Novel multi-stage centrifugal pump device and manufacturing method

A centrifugal pump and a new type of technology, which are applied to the components, pumps, and pump components of a pumping device for elastic fluids, can solve the problems of increased processing difficulty, many casting defects, affecting efficiency, etc., so as to achieve increased manufacturing costs, The effect of improving sealing performance and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below by specific examples.

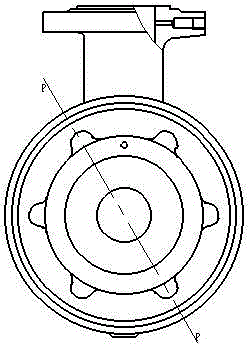

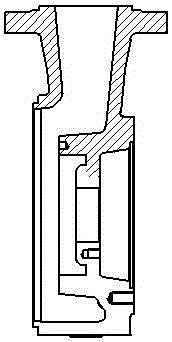

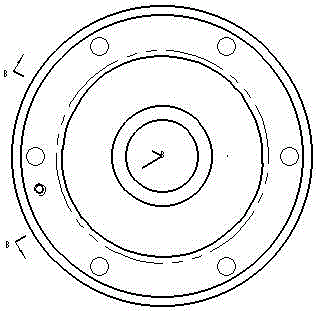

[0026] Combined with the accompanying drawings, a new type of multi-stage centrifugal pump device consists of a water inlet section (attached figure 1 , 2 ), outlet section (attached image 3 , 4 ), shaft box body, middle section, stuffing box body (attached Figure 5 , 6 ), the cooling device, the water inlet section and the water outlet section do not include the perforation seat and base for fixing the perforation rod, the stuffing box body is cast separately from the cooling device, the water inlet section, the water outlet section, the stuffing box body , The middle section is precision casted with high-priced materials, and the shaft body and cooling device are casted with low-priced materials.

[0027] attached Figure 7 , 8 It is the water inlet section of the prior art, with the improved attached figure 1 , 2 The inlet section shown is compared with the attached Figure 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com