Welding, positioning and flaw detection method for automobile muffling pipe

A technology for mufflers and automobiles, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of low welding seam inspection and repair efficiency, inability to make targeted improvements, and inability to mark cracks in time, so as to improve the efficiency and convenience of flaw detection and positioning. Repair welding, convenient and quick removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

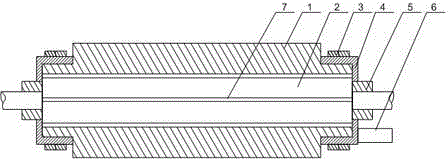

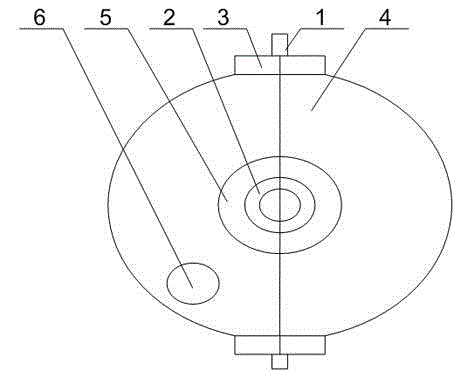

[0025] Such as figure 1 and figure 2 As shown, this embodiment includes the following steps,

[0026] (A) First place the main part of the outer tube 2 in the filling cavity, and the two ends of the outer tube 2 are fastened by the fixing ring 5;

[0027] (B) The two partition plates 1 are attached to the outer walls of the upper and lower sides of the outer tube 2 respectively, and then the movable ends of the two half cylinders 4 are connected and fixed;

[0028] (C) Start to inject gypsum slurry into the injection hole 6 until the gypsum slurry fills the cavity completely;

[0029] (D) The end of the outer tube 2 fastened by the fixing ring 5 is connected to the trachea, and the trachea injects compressed air into the outer tube 2;

[0030] The above-mentioned steps include two semi-cylindrical bodies 4 with both ends closed and hinged to each other and fixing rings 5 fixed at both ends of the semi-cylindrical body 4, the fixing ring 5 is coaxial with the semi-cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com