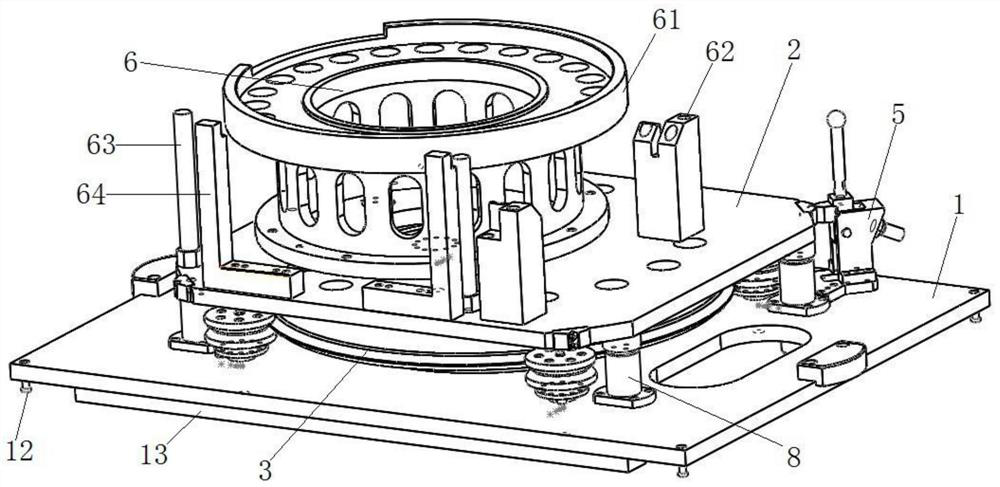

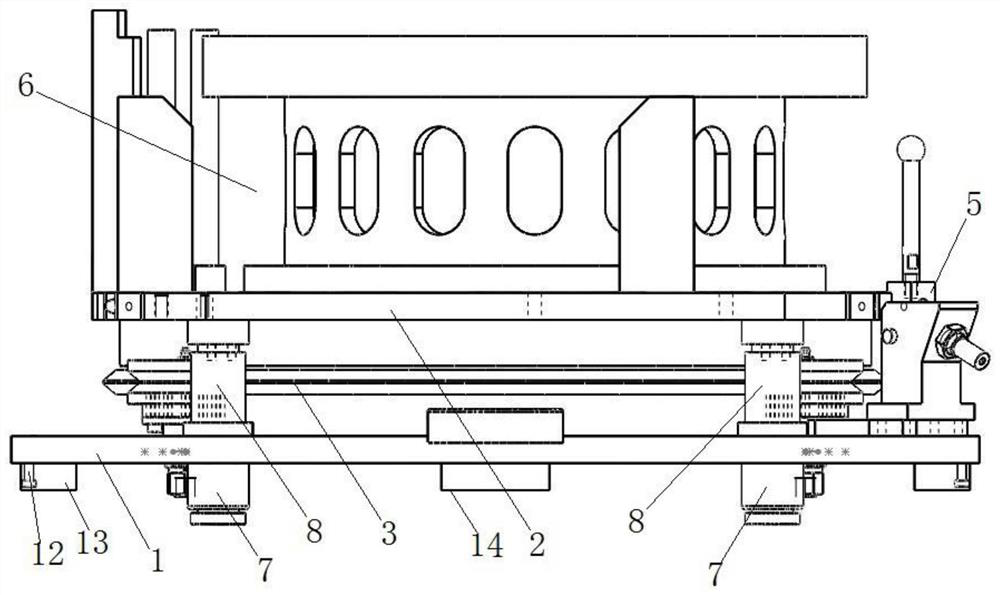

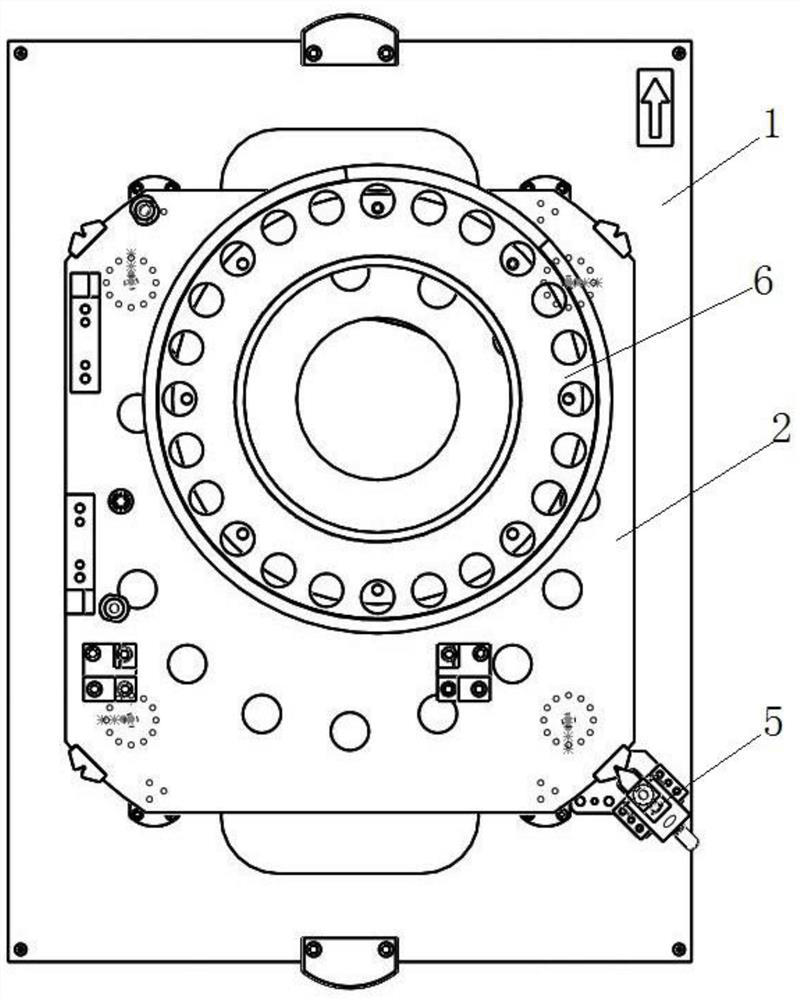

Conveying tray for transmission assembly line

A transmission and assembly line technology, applied in transportation and packaging, metal processing, metal processing equipment, etc., can solve problems affecting transmission detection and press-fitting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] The difference from Embodiment 1 is that in this embodiment, the above-mentioned anti-rotation structure includes a guide column with a non-circular cross section, such as an ellipse or a square. By making the cross-section of the guide column non-circular, the positioning plate 2 can be prevented from rotating relative to the turntable 3 by its own non-circular cross-section.

Embodiment 3

[0050] The difference between it and Embodiment 1 or Embodiment 2 is that in this embodiment, a runner is also included, and the runner is rotatably installed on the surface of the bottom plate 1, and the runner is rotatable with the bottom plate 1 through the axle and the runner bearing. Connection, such as turntable 3 and base plate 1. The circumferential side wall of the runner is in contact with the circumferential side wall of the turntable 3 . The setting of the runner makes the external drive mechanism, such as the motor installed on the base plate 1, the motor drive the runner to rotate through mechanical connection, and the runner drives the turntable 3 to rotate through friction, compared with the one in the first embodiment. Manual or other ways to realize the rotation of the positioning plate 2, the efficiency of this embodiment is better.

Embodiment 4

[0052] It differs from Embodiment 1 or Embodiment 2 in that: if Figure 7 and Figure 8 As shown, the present embodiment is similar to Embodiment 3, and a rotatable runner 9 is installed on the surface of the bottom plate 1, and the runner 9 is rotatably connected with the bottom plate 1 through the wheel shaft and the runner bearing, and the circumferential side wall of the runner 9 It is in contact with the circumferential side wall of the turntable 3; but in this embodiment, the number of runners 9 is not less than three, and the three runners 9 are evenly distributed in the circumferential direction. In this embodiment, the preferred runners 9 have four Secondly, in the present embodiment, the contact surface of the runner 9 and the turntable 3 is V-shaped, that is, the circumferential side wall of the runner 9 is provided with an annular groove with a V-shaped opening, and the circumferential side wall of the turntable 3 is set to Inverted V shape cooperates with runner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com