Cable insulation layer grinding machine

A cable insulation and grinding machine technology, which is applied in the direction of grinding racks, grinding machine parts, grinding machines, etc., can solve the problems of slow construction progress, low work efficiency, and heavy processing workload, and achieve convenient use and grinding The effect of uniform degree and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to achieve technical means, the creation characteristics, the achievement of the present invention is readily understood, and the present invention is further illustrated in connection with the specific illustration below.

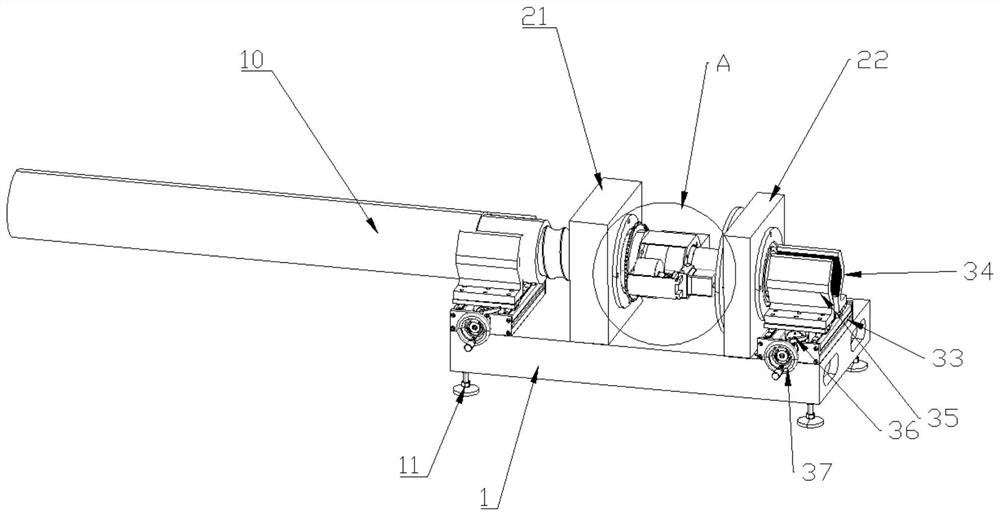

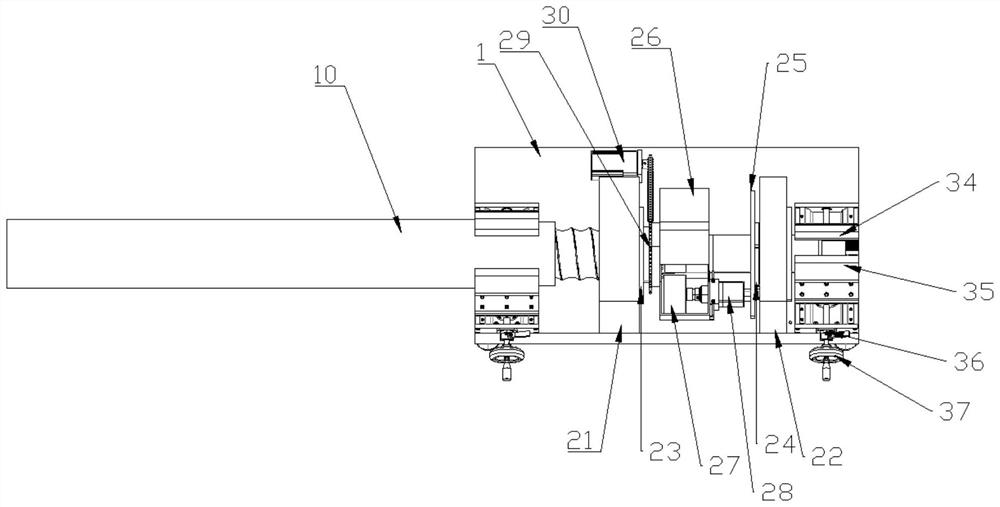

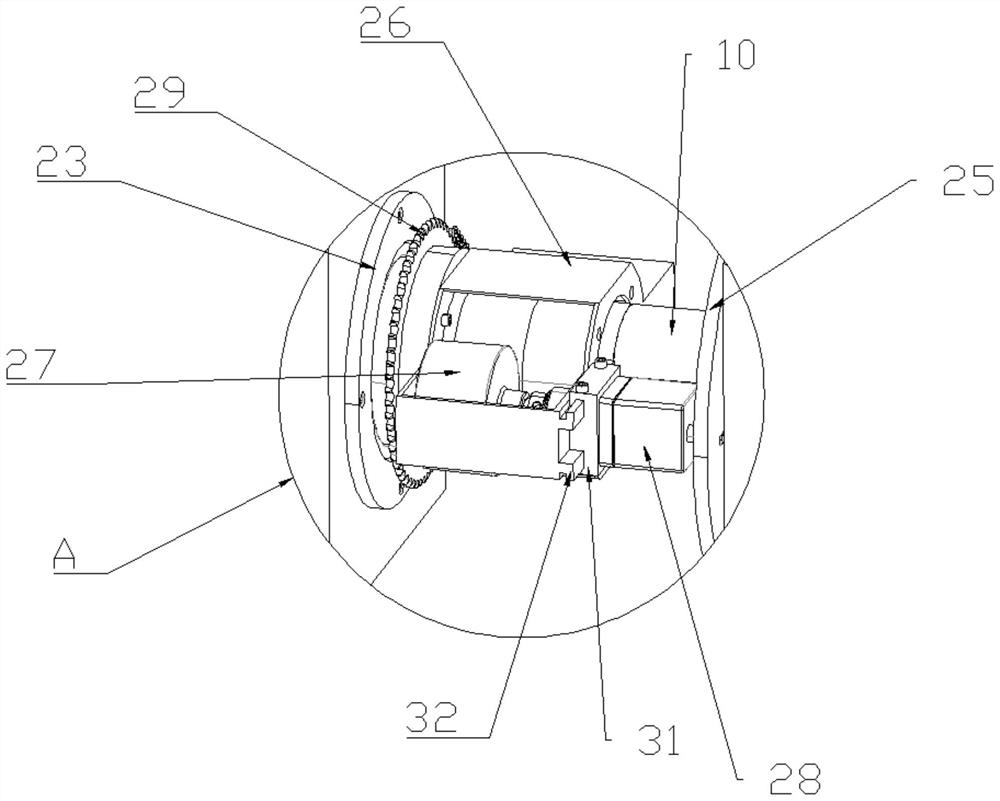

[0017] Such as Figure 1 ~ 3 Distance

[0018] This embodiment provides a cable insulating layer grinding machine, including a base 1 and a grinding device and a clamping mechanism disposed on the base 1, the clamping mechanism being disposed on both sides of the grinding device, including symmetry The first bracket 21 and the second bracket 22 are disposed on the base 1, mounted between the first support 21 and the second bracket 22, and the intermediate mounting of the first support 21 has first. The bearing sleeve 23, the outer end of the first bearing sleeve 23 is rotatably connected to the grinding wheel mechanism, and the intermediate corresponding position of the second support 22 is provided with a second bearing sleeve 24, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com