Building decoration material aluminum-plastic plate molding processing method

A technology for building decoration materials and processing methods, which is applied in the field of aluminum-plastic panel preparation, can solve problems such as increased operating costs, troublesome operation, and damage to aluminum-plastic panels, and achieves the goals of controlling the bending angle, improving bending quality, and improving convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

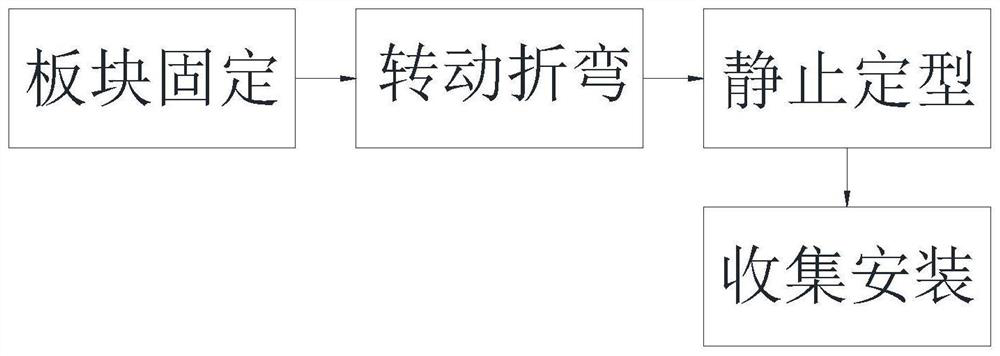

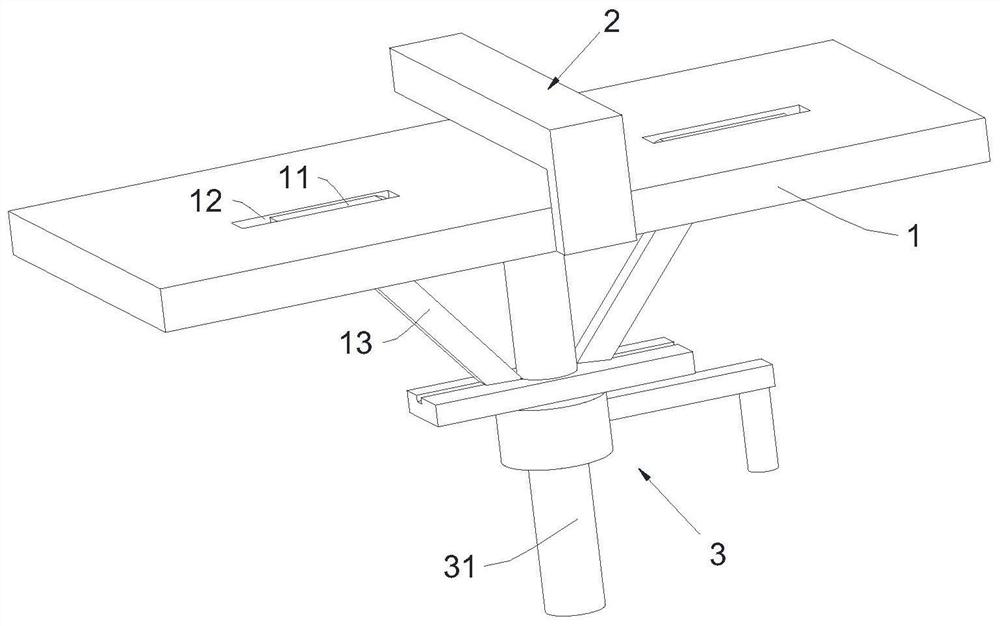

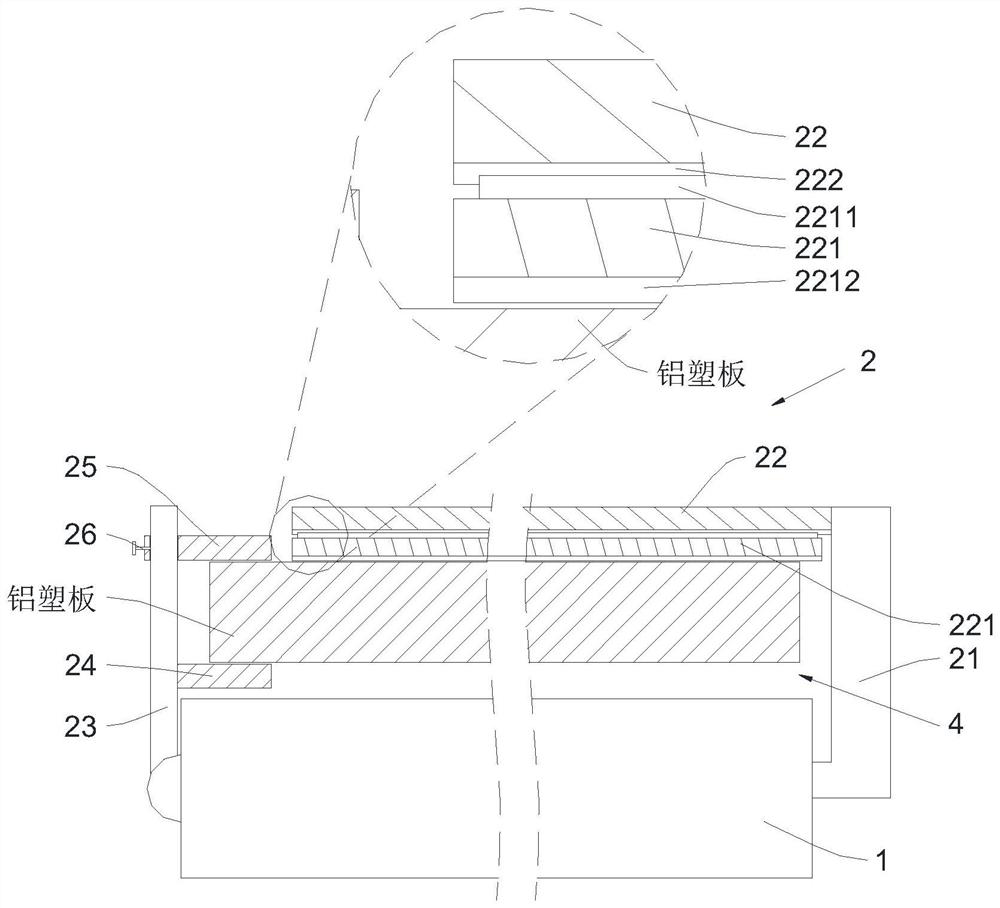

[0034] refer to figure 2 As shown, it is a molding processing method of aluminum-plastic panels for building decoration materials disclosed in the present invention. In order to facilitate the bending and adjustment of the angle of the aluminum-plastic panels during actual production, it includes a pair of aluminum-plastic panels for bending adjustment. Bending equipment, the aluminum-plastic plate bending equipment includes a fixed plate 1, the side of the fixed plate 1 is provided with a positioning device 2 for positioning the aluminum-plastic plate, and one side of the fixed plate 1 is rotated and installed to drive the aluminum-plastic plate to bend. drive rod 11, the fixed plate 1 is provided with an embedding groove 12 for the drive rod 11 to be embedded and installed, and the side of the fixed plate 1 far away from the drive rod 11 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com