Virus treatment system for elevator car

A treatment system and elevator car technology, applied in the field of virus treatment systems, can solve the problems of increased workload of operators, heavy workload of operators, inconvenient elevator operation, etc., achieve good disinfection effect, good spraying effect, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

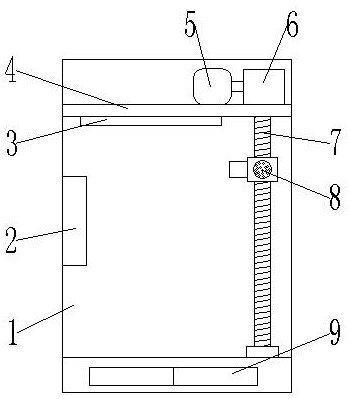

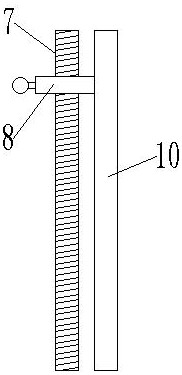

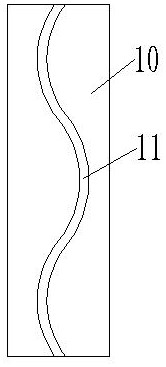

[0038] like Figure 1-5 As shown, a virus treatment system for an elevator car includes a car 1; the top inside the car 1 is provided with a support plate 4, and the upper side of the support plate 4 is provided with a first motor 5; The output shaft of the first motor 5 is connected with a speed changer 6, and the output shaft of the first motor 5 is connected with the input shaft of the speed changer 6; the output shaft of the speed changer 6 is connected with a threaded rod 7; There is a disinfection mechanism 8, and the first motor 5 drives the threaded rod 7 to rotate, so that the disinfection mechanism 8 moves up and down; the inside of the car 1 is provided with a guide plate 10; the guide plate 10 is provided with a guide groove 11; One side of the rod 7; one end of the disinfection mechanism 8 is connected with the guide groove 11; the lower side of the support plate 4 is provided with a disinfection lamp 3, and the disinfection lamp 3 is an ultraviolet lamp, which re...

Embodiment 2

[0047] The difference from Embodiment 1 is that in order to enable the sprayer to work fully and fully disinfect the inner wall of the car, the trajectory curve S of the guide groove, the rotational speed W of the output shaft of the transmission, and the pitch P of the threaded rod satisfy the following relationship: S=A·sinWPT; wherein, A is the correlation coefficient, and the value range is 0.8-1.2; the unit of W is n / s; the unit of P is mm, and T is time, and the unit is s. When A is less than 0.8, the swinging range of disinfection mechanism 8 is small, and the inner wall of the car cannot be fully disinfected, and the disinfection medium sprayed by disinfection mechanism 8 cannot cover the bottom of the inner side of car 1; when A is greater than 1.2, the disinfection The amplitude of the swing of mechanism 8 is relatively large, and the sterilizing medium ejected by sterilizing mechanism 8 cannot evenly cover the bottom of the inner side of car 1, and dead spots of ster...

Embodiment 3

[0049] In conjunction with Embodiment 2, when A is 0.6, the swing angle of the disinfection mechanism 8 in the car 1 is 40 degrees, and after the disinfection mechanism 8 moves from the top of the threaded rod 7 to the bottom, the coverage of the disinfectant on the side wall of the car rate is 50%, that is, the car 1 cannot be fully disinfected; when A is 0.8, the swing angle of the disinfection mechanism 8 in the car 1 is 50 degrees, and the disinfection mechanism 8 moves from the top of the threaded rod 7 to the After the bottom, the coverage rate of the disinfectant on the side wall of the car is 80%, basically realizing the disinfection in the car 1; when A is 1, the swing angle of the disinfection mechanism 8 in the car 1 is 65 degrees, After the disinfection mechanism 8 moves from the top of the threaded rod 7 to the bottom, the coverage rate of the disinfectant solution on the side wall of the car is 85%, basically realizing the disinfection in the car 1; when A is 1.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com