A kind of preparation method of methanol fuel decomposition catalyst with high stability

A methanol fuel, high-stability technology, applied in electrolysis components, electrolysis process, electrodes, etc., can solve the problems of decreased activity, affect catalytic activity, reduce catalyst stability, etc., achieve increased activity, improve catalytic performance, inhibit liquid phase The effect of the formation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

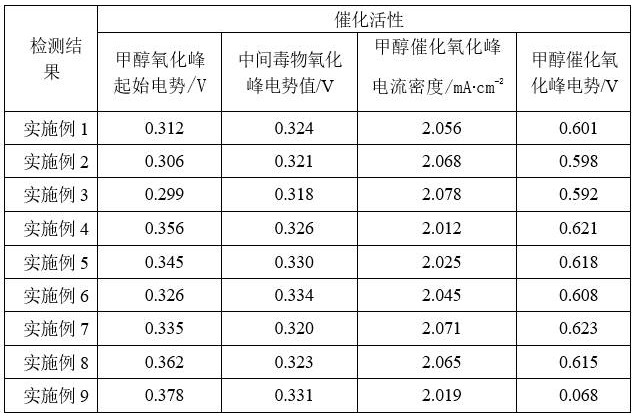

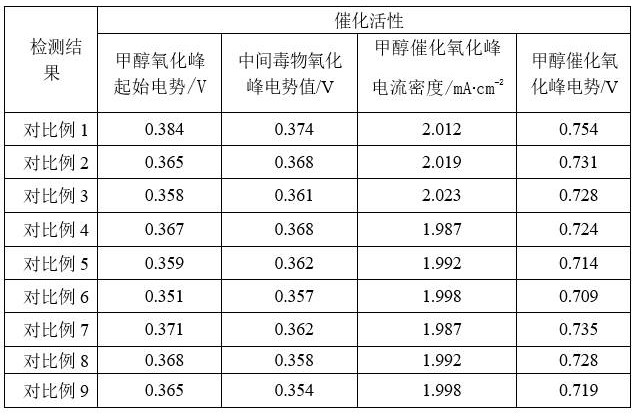

Examples

Embodiment 1

[0034]According to the molar ratio of Cu:Mg:Al 1:2:1, take copper nitrate, magnesium nitrate and aluminum nitrate and mix them respectively. According to the mass ratio of 1:25, take the mixture and add it to deionized water, stir and mix and collect the dissolved solution, according to the volume ratio of 1:1, add the dissolving solution to the 10% sodium carbonate solution by mass fraction, stir and mix and magnetically stir to obtain the base liquid, add dropwise 5% sodium hydroxide solution by mass fraction to the base liquid, stir and mix And control the pH of the matrix liquid to be 9. After the dropwise addition is completed, stir and mix and leave it to stand at room temperature for 3 hours, remove the lower layer of precipitate and place it at 75°C for crystallization treatment for 3 hours to obtain crystallized particles and wash them with deionized water After the washing liquid is neutral, then vacuum freeze-dry, crush and pass through a 500-mesh sieve, take the sie...

Embodiment 2

[0038] According to the molar ratio of Cu:Mg:Al 1:2.5:1, take copper nitrate, magnesium nitrate and aluminum nitrate and mix them respectively, according to the mass ratio of 1:25, take the mixture and add it to deionized water, stir and mix and collect the dissolved solution, according to the volume ratio of 1:1, add the dissolving solution to the 10% sodium carbonate solution by mass fraction, stir and mix and magnetically stir to obtain the base liquid, add dropwise 5% sodium hydroxide solution by mass fraction to the base liquid, stir and mix And control the pH of the matrix liquid to be 9. After the dropwise addition is completed, stir and mix and leave it to stand at room temperature for 4 hours, remove the lower precipitate and place it at 77°C for crystallization treatment for 4 hours to obtain crystallized particles and wash them with deionized water After the washing liquid is neutral, then vacuum freeze-dry, crush and pass through a 500-mesh sieve, take the sieved pa...

Embodiment 3

[0042] According to the molar ratio of Cu:Mg:Al 1:3:1, take copper nitrate, magnesium nitrate and aluminum nitrate and mix them respectively. According to the mass ratio of 1:25, take the mixture and add it to deionized water, stir and mix and collect the dissolved solution, according to the volume ratio of 1:1, add the dissolving solution to the 10% sodium carbonate solution by mass fraction, stir and mix and magnetically stir to obtain the base liquid, add dropwise 5% sodium hydroxide solution by mass fraction to the base liquid, stir and mix And control the pH of the matrix liquid to be 10. After the dropwise addition is completed, stir and mix and place it at room temperature for 3-5 hours of static aging, remove the lower precipitate and place it at 80°C for crystallization treatment for 5 hours to obtain crystallized particles and use deionized Wash with water until the washing liquid is neutral, then vacuum freeze-dry, crush and pass through a 500-mesh sieve, take the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com