Self-climbing type installation system of steel cable tower

An installation system and a technology for steel cable towers, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve problems such as increasing construction costs, improving work efficiency, and disadvantages, and achieving easy installation and dismantling, reduced disassembly, and clear force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] The self-climbing installation method of the steel cable tower of the present application can be realized by the self-climbing installation system of the steel cable tower, and the self-climbing installation system of the steel cable tower can be implemented more efficiently and conveniently. A self-climbing installation method for a cable tower; the self-climbing installation method for a cable tower is a method for using a self-climbing installation system for a cable tower, and the self-climbing installation system for a cable tower is a self-climbing installation system for a cable tower. The self-climbing installation method of the steel cable tower and the self-climbing installation system of the steel cable tower are interdependent and mutually conditioned.

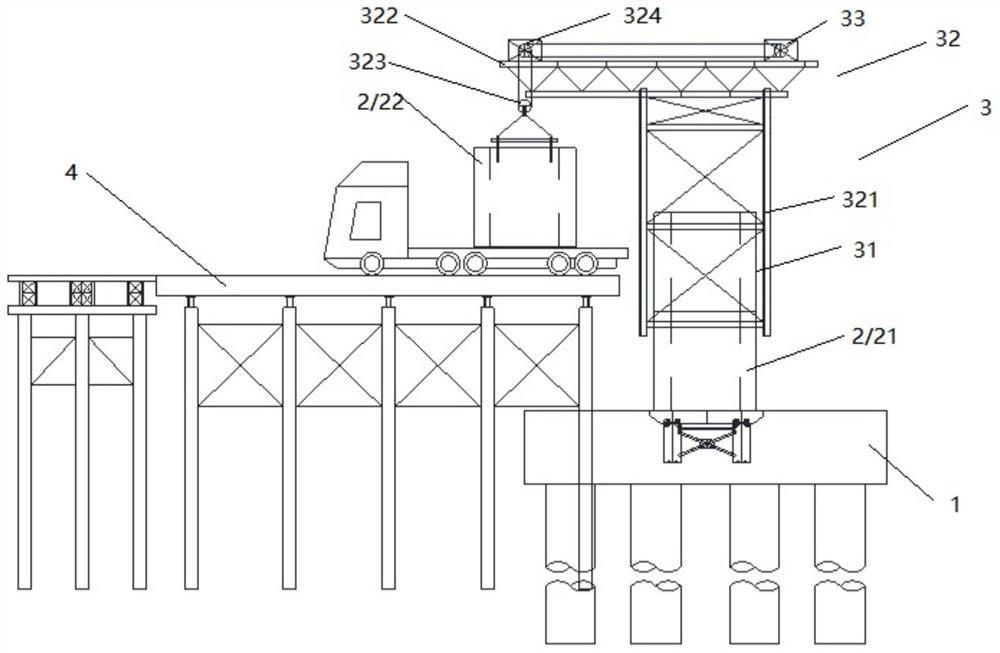

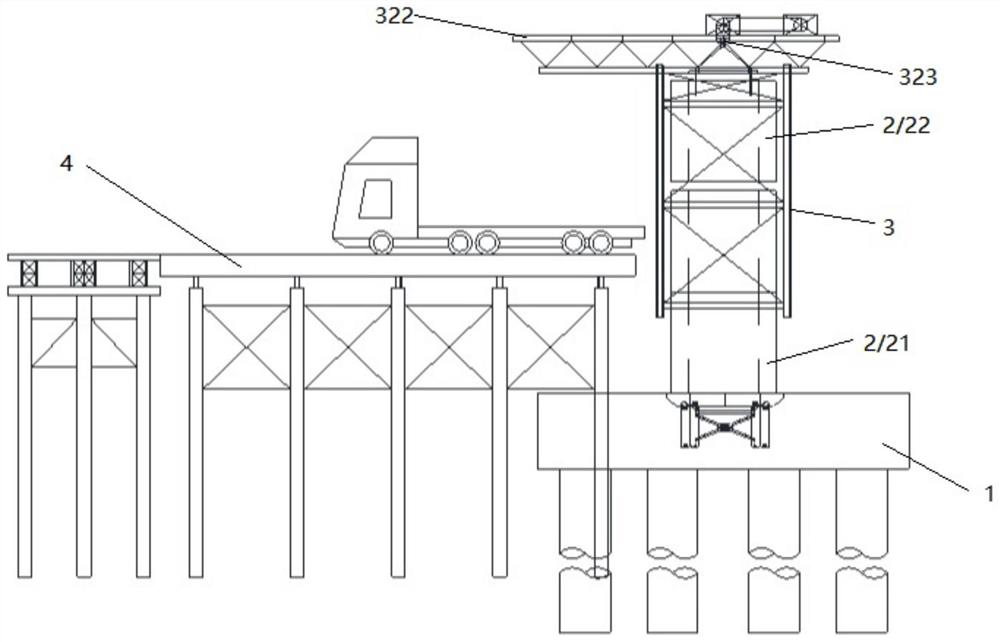

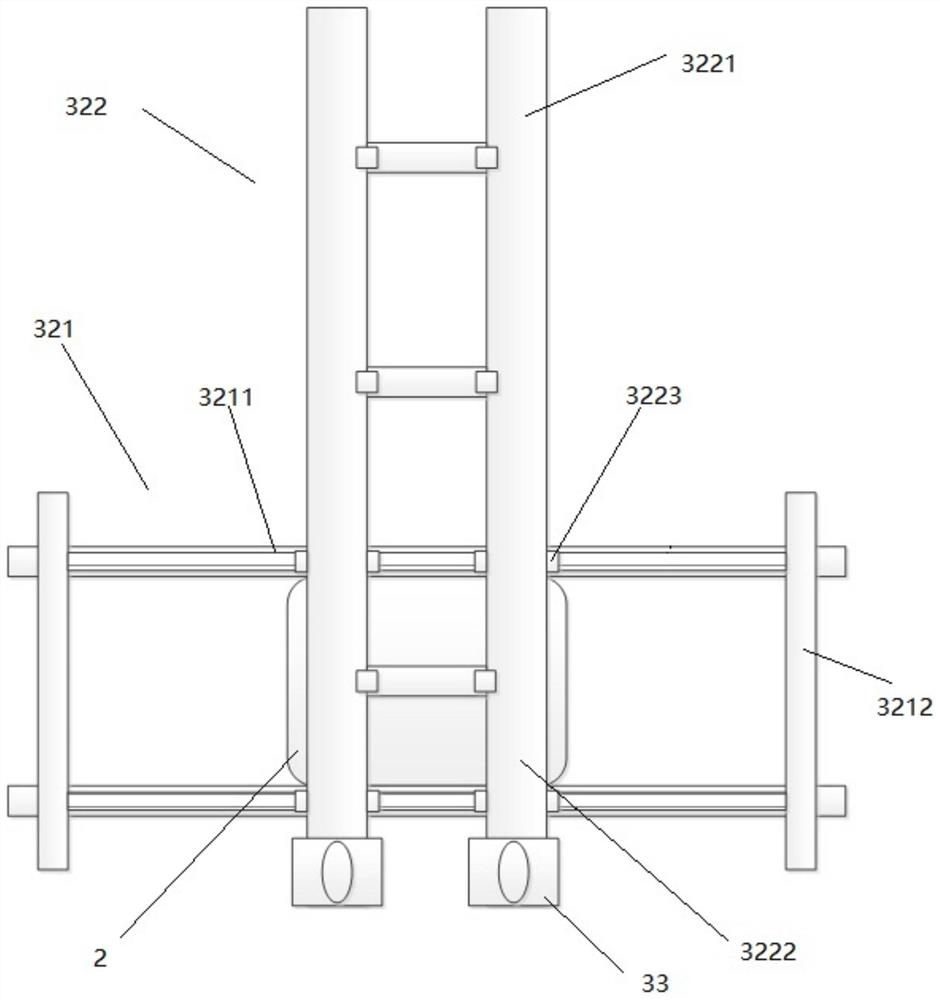

[0051] refer to figure 1 Before implementing the self-climb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com