Novel multifunctional four-way reversing valve

A four-way reversing valve, multi-functional technology, applied in the field of reversing valves, can solve the problems of increasing pipeline resistance, increasing design and manufacturing costs, inconvenient connection, etc., and achieve the effect of reducing system energy consumption and reducing design and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

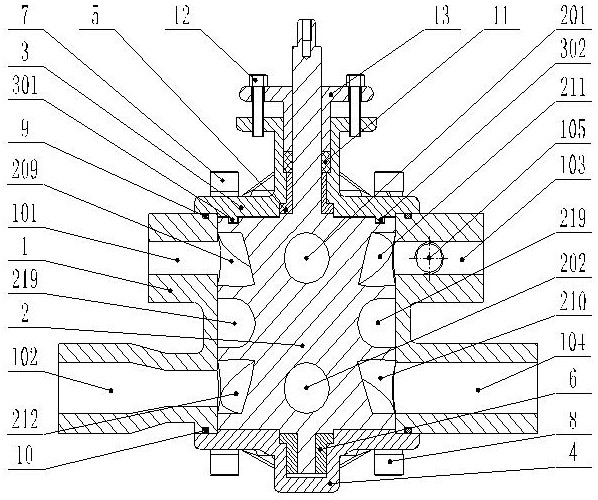

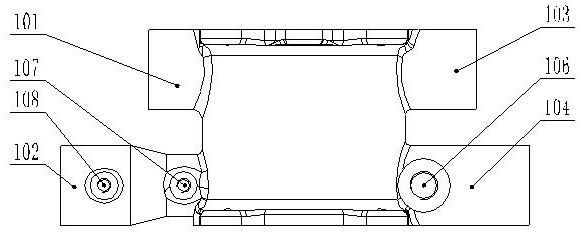

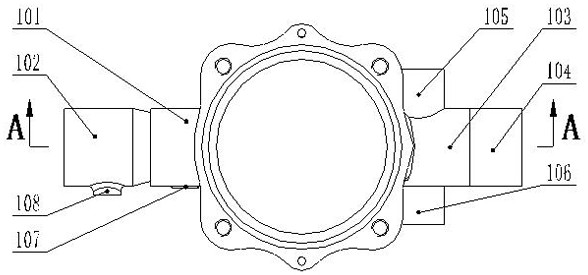

[0036] Such as Figure 1 to Figure 7As shown, a new multifunctional four-way reversing valve includes a valve seat 1 and a valve core 2, the valve seat 1 is cylindrical, the valve seat 1 includes 4 fluid connection ports, and the 4 fluid The connecting ports are horizontally connected with the valve seat 1 and communicated with the inner cavity of the valve seat 1, and the four fluid connection ports include a supply-side inlet 101 and a supply-side outlet 102 for connecting to the main supply-side system. The load-side inlet 103 and the load-side outlet 104 of the user-side system; the valve core 2 is sealed and rotatably assembled in the inner cavity of the valve seat 1, the rotation axis of the valve core 2 is in the up-down direction, and the upper rotation axis of the valve core 2 is provided with a useful At the connection part connected with the driving device, the upper part of the valve seat 1 is fixedly connected to the upper gland 3 by screw one 7, and the lower par...

Embodiment 2

[0048] The difference between this embodiment and embodiment 2 is that the third channel 203 and the fourth channel 204 on the valve core 2 have different structures. Such as Figure 12 As shown, the four passages on the spool 2 include a first passage 201, a second passage 202, a third passage 203 and a fourth passage 204, and the first passage 201 and the second passage 202 are formed by the through-spool 2 diameter straight holes, the first passage 201 is located above the second passage 202 and parallel to the second passage 202, the third passage 203 and the fourth passage 204 are formed by the passages arranged inside the valve core 2 Formed, the hole can be made of pipes, the third channel 203 and the fourth channel 204 are symmetrical to the center of the rotation axis of the valve core 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com