Compressor assembly and air conditioner

A technology for compressors and components, which is applied in the direction of compressors, refrigeration components, machines/engines, etc. It can solve the problems that the vibration-damping structure is difficult to meet the vibration-damping requirements, the axial and longitudinal vibration of the compressor, and the reduction of user comfort, etc., to achieve Good adaptability, reduced excitation, and improved vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

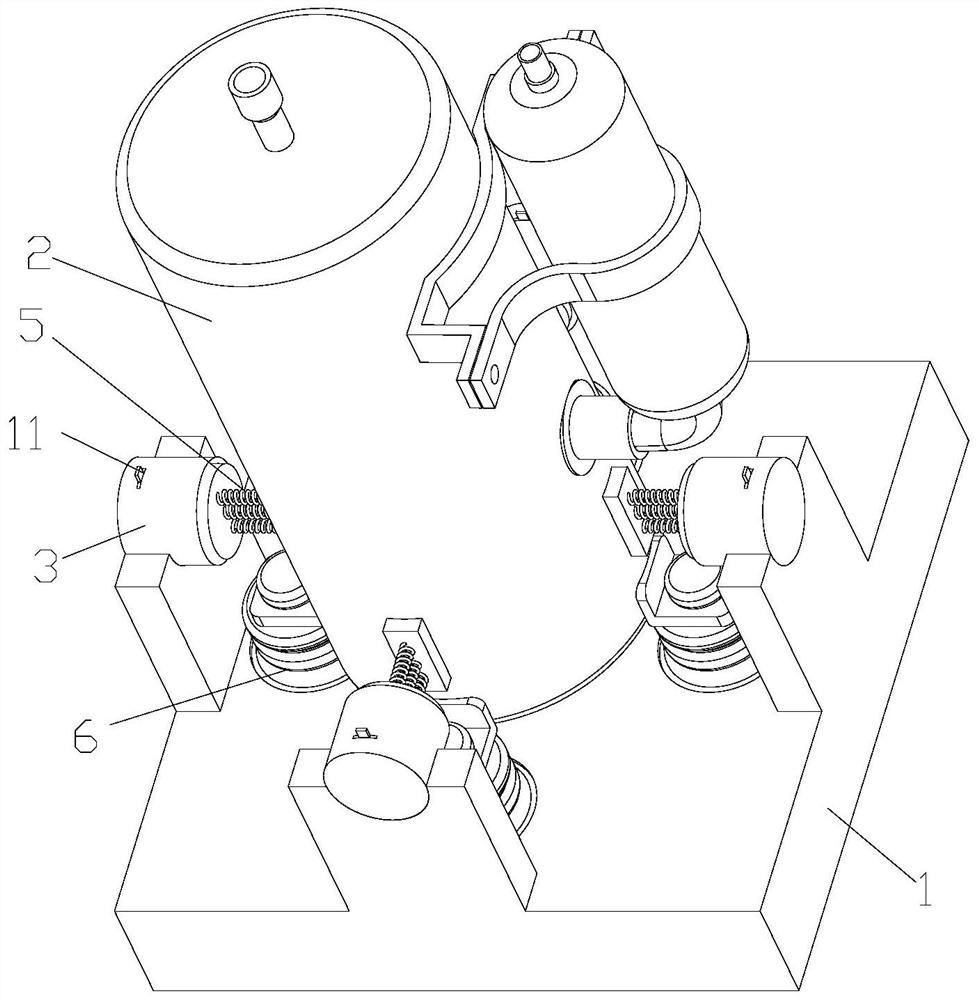

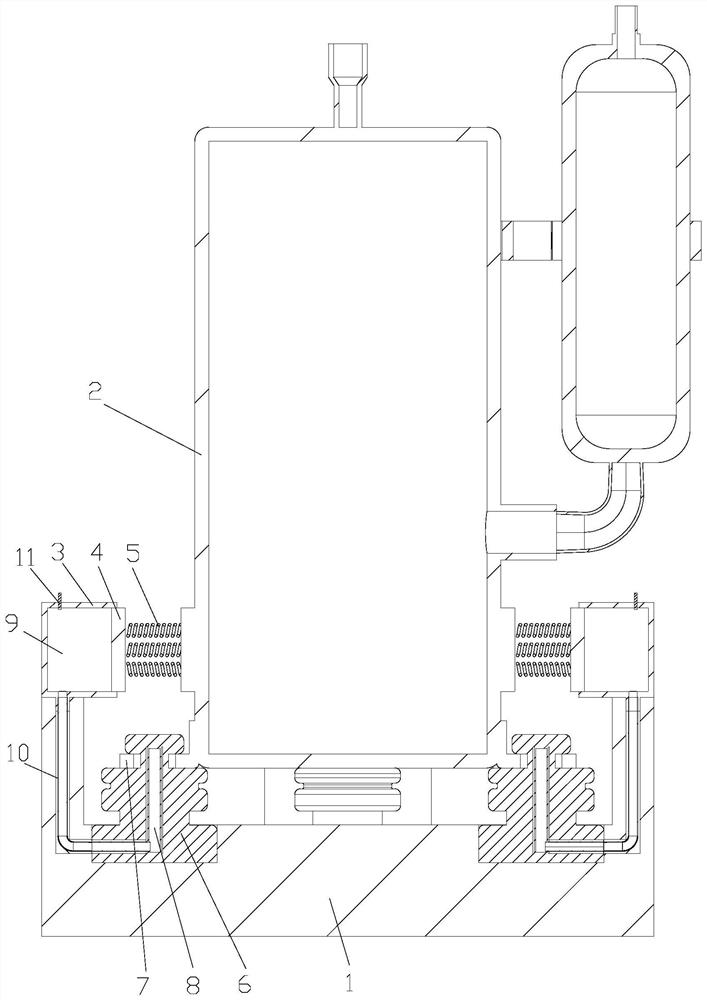

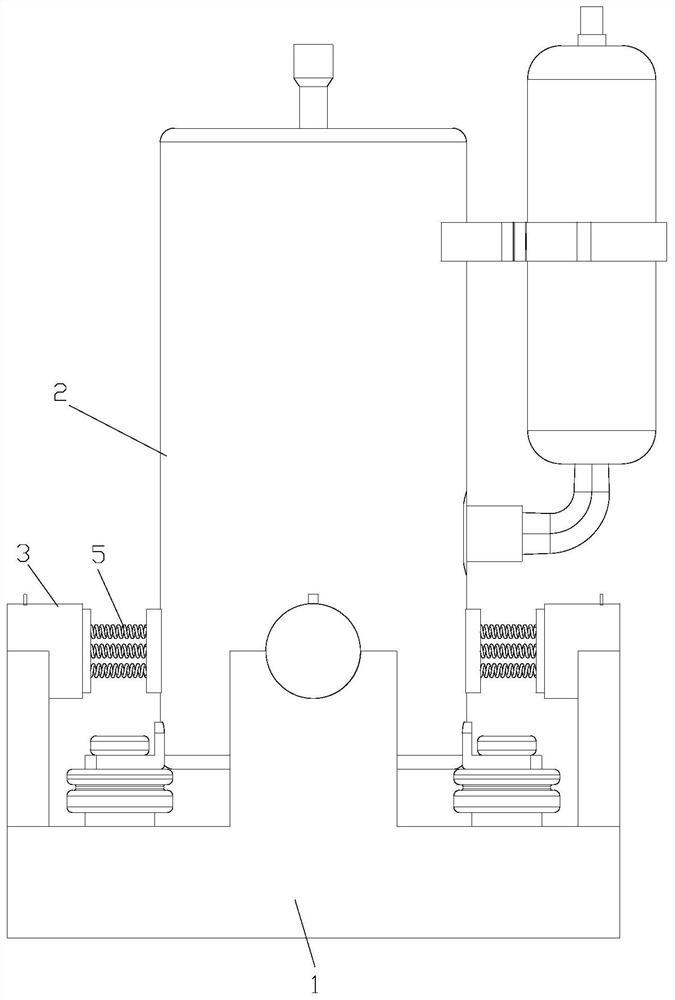

[0024] see in conjunction Figure 1 to Figure 3 As shown, according to the embodiment of the present application, the compressor assembly includes a chassis 1, a compressor body 2, a first damping structure and a second vibration damping structure, and the first vibration damping structure is connected between the chassis 1 and the compressor body 2 , and provide the compressor main body 2 with a vibration damping force in the radial direction, the second damping structure is connected between the chassis 1 and the compressor main body 2, and provide the compressor main body 2 with an axial vibration damping force .

[0025] The main body of the compressor 2 performs vibration reduction in the radial direction through the first vibration reduction structure, and performs vibration reduction in the axial direction through the second vibration reduction structure, so the first vibration reduction structure and the second vibration reduction structure can simultaneously compress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com