Automatic high-temperature adhesive tape wrapping device

A high-temperature tape, automatic technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of high labor stress, high-temperature tape position, different tightness, unfavorable processing automation introduction, etc., to achieve quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

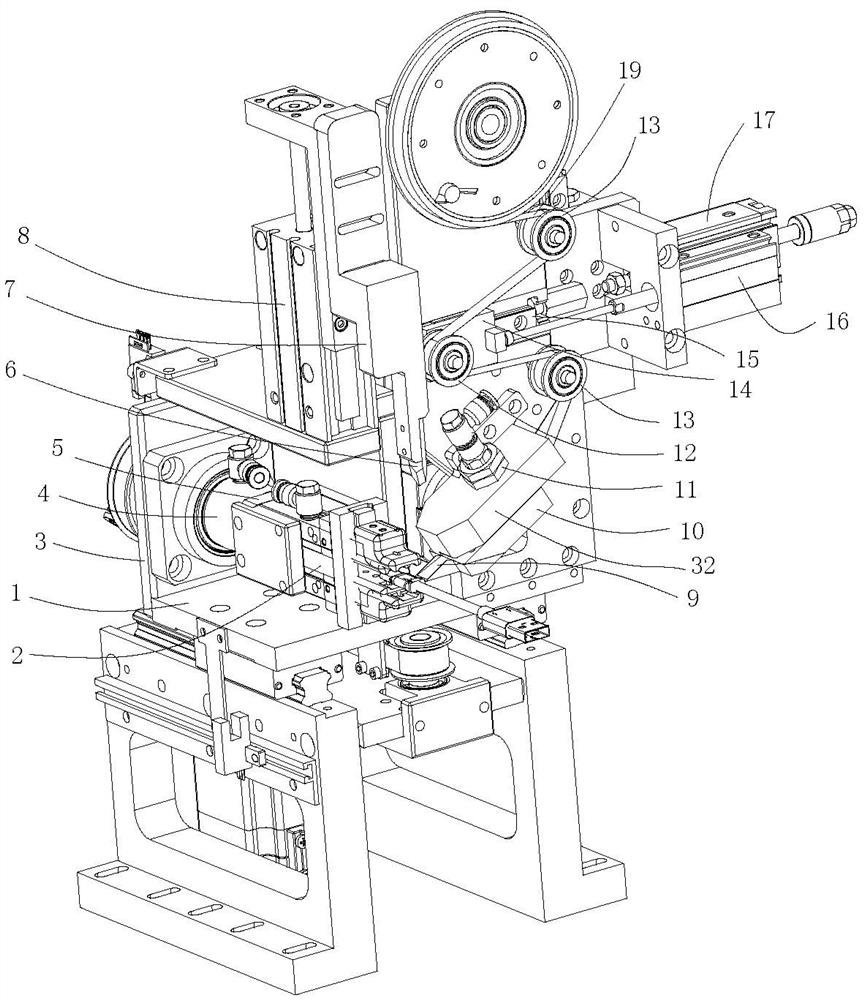

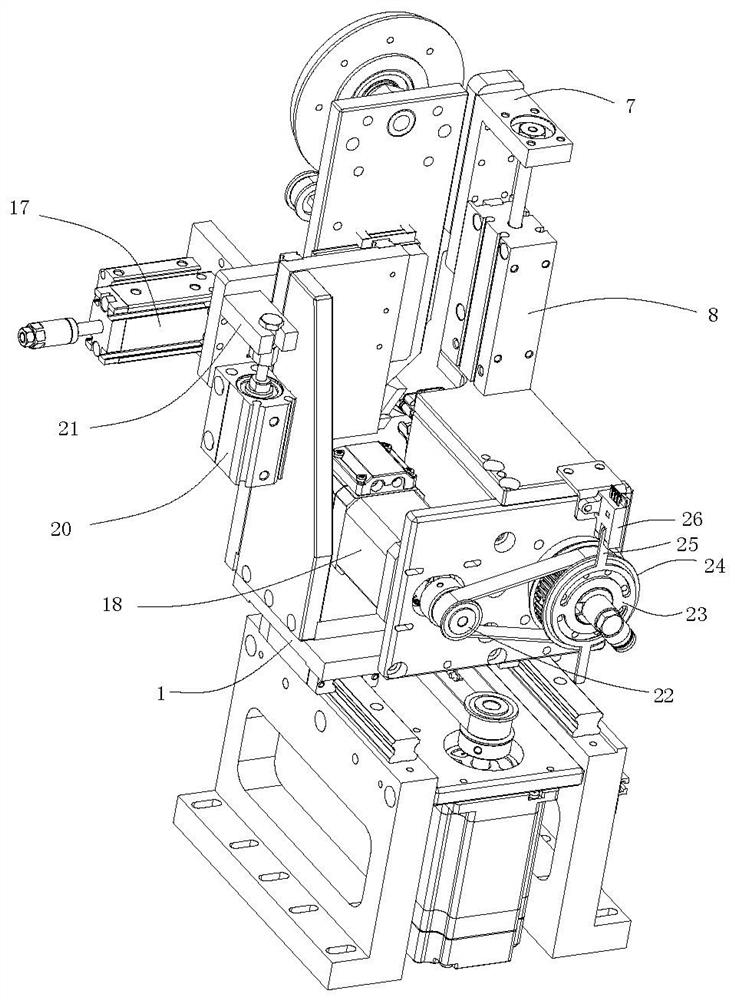

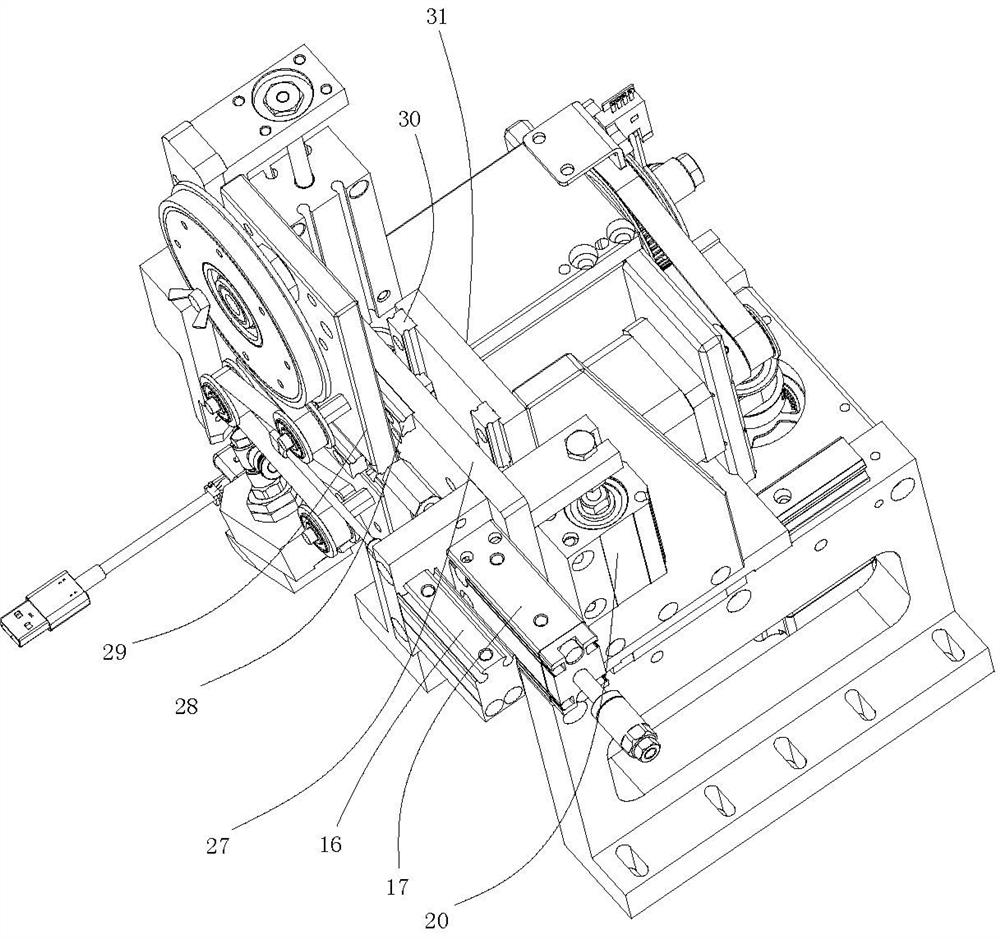

[0025] Embodiment 1: a kind of device of wrapping high-temperature adhesive tape 19 automatically, it comprises

[0026] The substrate 1 is fixed with a jig 2 for clamping the cable connector, and the jig 2 is connected with a rotating mechanism for driving the jig 2 to rotate,

[0027] A passive conveying mechanism for conveying the high-temperature adhesive tape 19 to the cable, the passive conveying mechanism includes a clamping mechanism for clamping the high-temperature adhesive tape 19, the clamping mechanism includes an upper fixing block 32, and the middle part of the lower end surface of the upper fixing block 32 is set There is a channel 33 for the passage of the high temperature adhesive tape 19, the lower end of the upper fixed block 32 is connected with the bottom block 10, the middle part of the upper end surface of the upper fixed block 32 is provided with a through hole 34 communicating with the channel 33, and the upper end surface is connected with a A movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com