Automatic encapsulating machine for bottoms of square lithium-ion battery cells

A technology of lithium ion battery and coating machine, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing and other directions, can solve the problem of low efficiency of artificial coating, save the amount of adhesive tape, and achieve good consistency , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

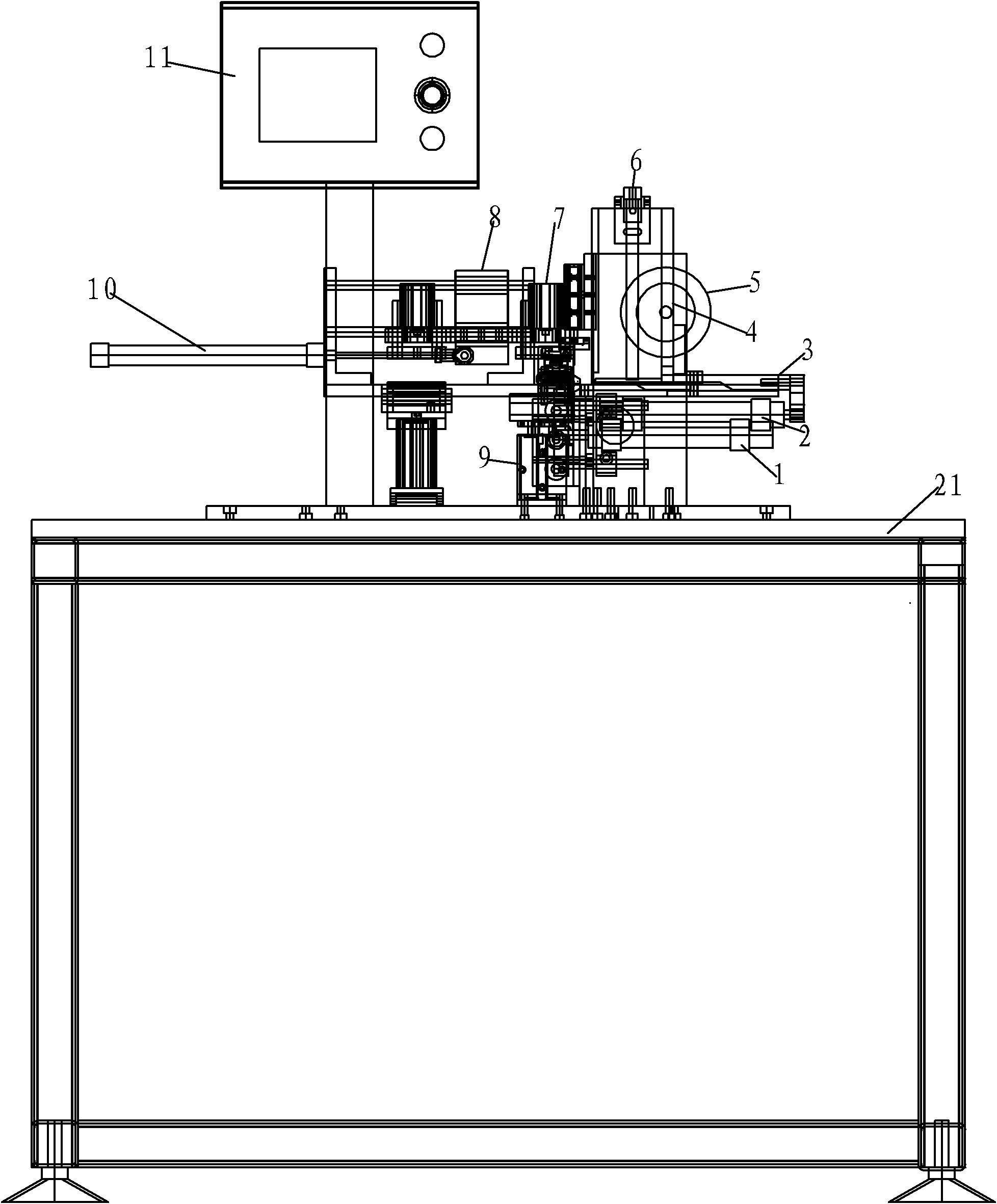

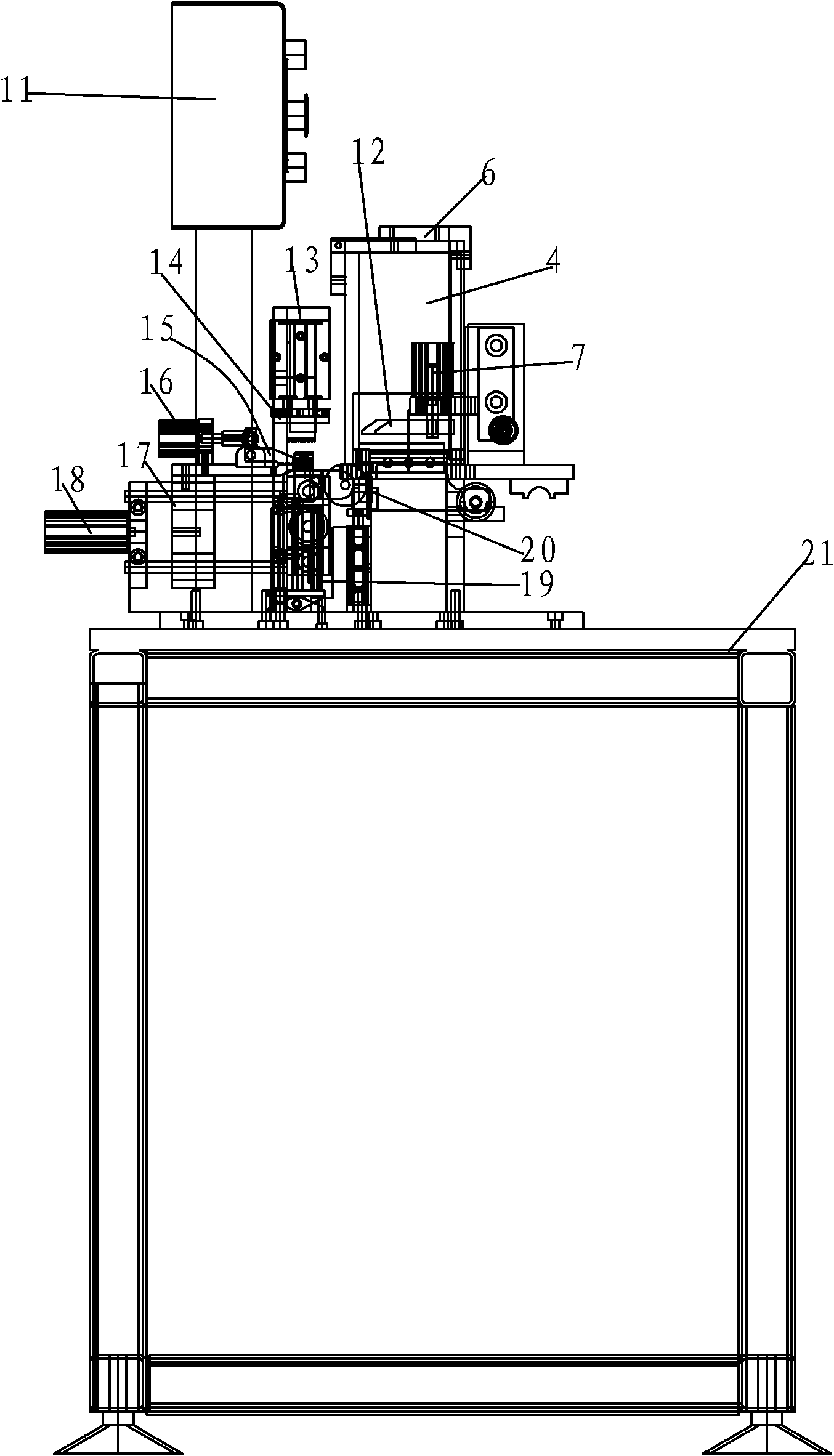

[0012] refer to Figure 1-Figure 2 , the present invention is a kind of automatic encapsulation of the bottom of a square lithium-ion battery cell, including a frame 21 and a cell blanking and transferring mechanism arranged on it, a cutting and adhesive paper mechanism, and a suction cup for sending the cell to the next step The feeding mechanism, the rubber rolling mechanism that completes the rubber wrapping, and the control and display mechanism.

[0013] The cell feeding and transferring mechanism includes a trough device, a cell moving plate and a feeding cylinder. The feeding chute device comprises a feeding chute 4, the upper wallboard of the feeding chute 4 is adjustable, and the electric core positioning block 6 is arranged on it, which can be turned up and adjusted. The feeding plate 3 is arranged under the lower trough 4, and the feeding plate 3 is pushed and fed by the feeding cylinder 2, and the battery cells to be coated are sent to the coating position, and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com