Vertical shaft cable and steel wire rope lowering and clamping device

A technology of wire rope and card device, applied in cable laying equipment and other directions, can solve the problems of cable and wire rope winding, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

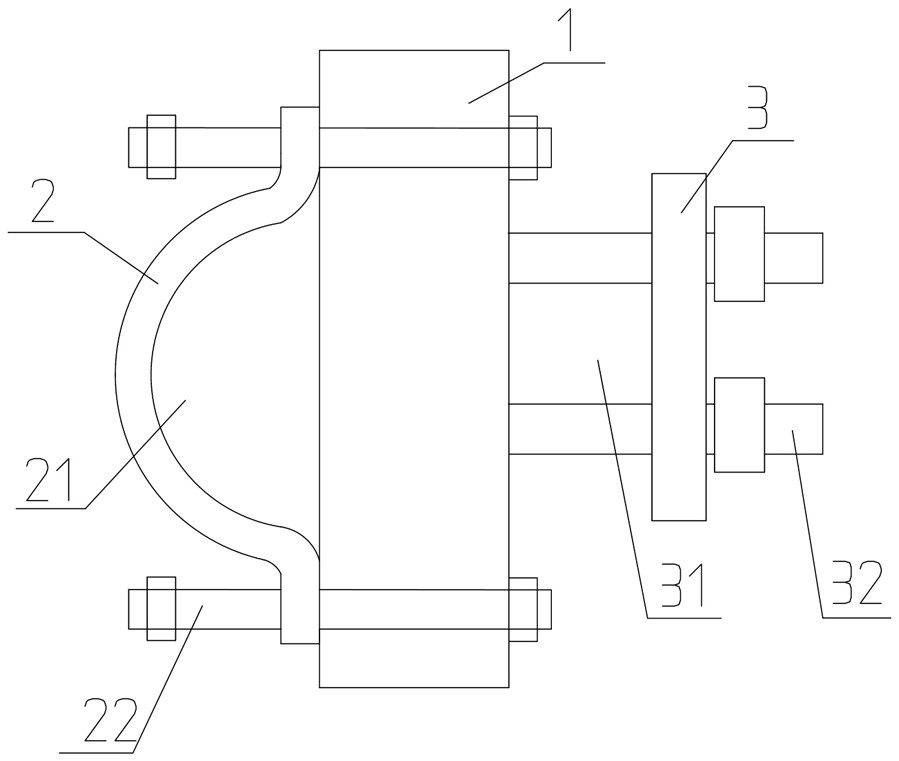

[0019] The invention provides a shaft cable and wire rope lowering device, such as figure 1 shown.

[0020] The shaft cable and wire rope lowering card device includes a lowering clamp body 1 and a first adjustment part corresponding to the left side of the lowering clamp body and a second adjustment part located on the right side of the lowering clamp body 1; the first adjustment part includes an arc The support baffle 2, and the arc-shaped support baffle 2 is buckled on the lower clamp body 1 and forms an accommodating cavity 21 for passing cables between the lower clamp body 1; the second adjustment part includes a The upper limit baffle 3 and a hollow cavity 31 for passing the wire rope is formed between the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com