Automatic silkworm cocoon picking equipment

An automatic and equipment technology, applied in the decomposition and restoration of textiles, animal husbandry, recycling technology, etc., can solve the problems of troublesome operation, time-consuming and laborious, etc., and achieve better scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of silkworm cocoon automatic extraction equipment, such as figure 1 As shown, it includes a base 1, a material storage frame 2, a gear motor 3, a placement component 4, and a pressing component 5. A placing assembly 4 is connected, and a pressing assembly 5 is connected between the placing assembly 4 and the output shaft of the geared motor 3 .

[0068] When people need to pick silkworm cocoons, they first place the grid clusters in the placement component 4, then start the deceleration motor 3, and the output shaft of the deceleration motor 3 rotates to drive the components of the pressing component 5 to pick out the cocoons and drop them into the storage frame 2 Inside, then take out the square cluster, close the reduction motor 3 and get final product.

Embodiment 2

[0070] On the basis of Example 1, such as Figure 2-4 As shown, the placement assembly 4 includes a support frame 41, a first support rod 42, a placement plate 43, and a first discharge plate 44. The right side of the base 1 is connected to the support frame 41, and the left side of the base 1 is connected to the front and rear sides. A support rod 42 , a placement plate 43 is connected between the top of the first support rod 42 and the support frame 41 , and a first discharge plate 44 is connected to the right side of the placement plate 43 .

[0071] When people need to pick silkworm cocoons, they first place the grid clusters on the left side of the placement plate 43, and then push the grid clusters to the right to the right side of the placement plate 43. After pressing the component 5 to extract the cocoons, people place the grid Push the cluster to the right to remove it.

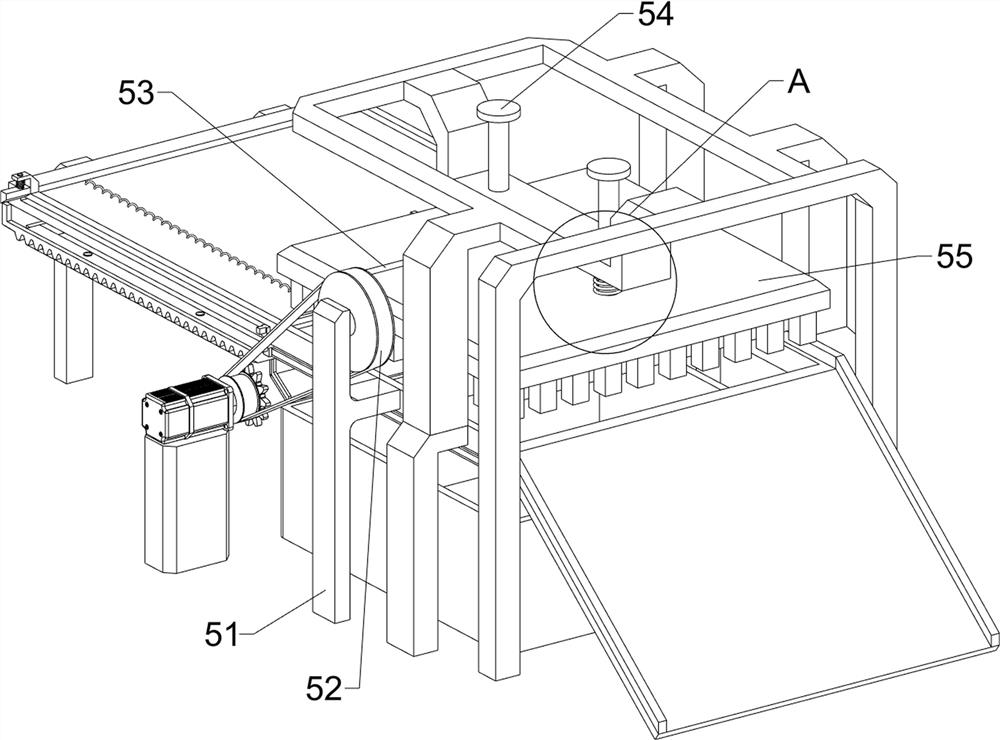

[0072] The pressing assembly 5 includes a second support rod 51, a transmission assembly 52, a ...

Embodiment 3

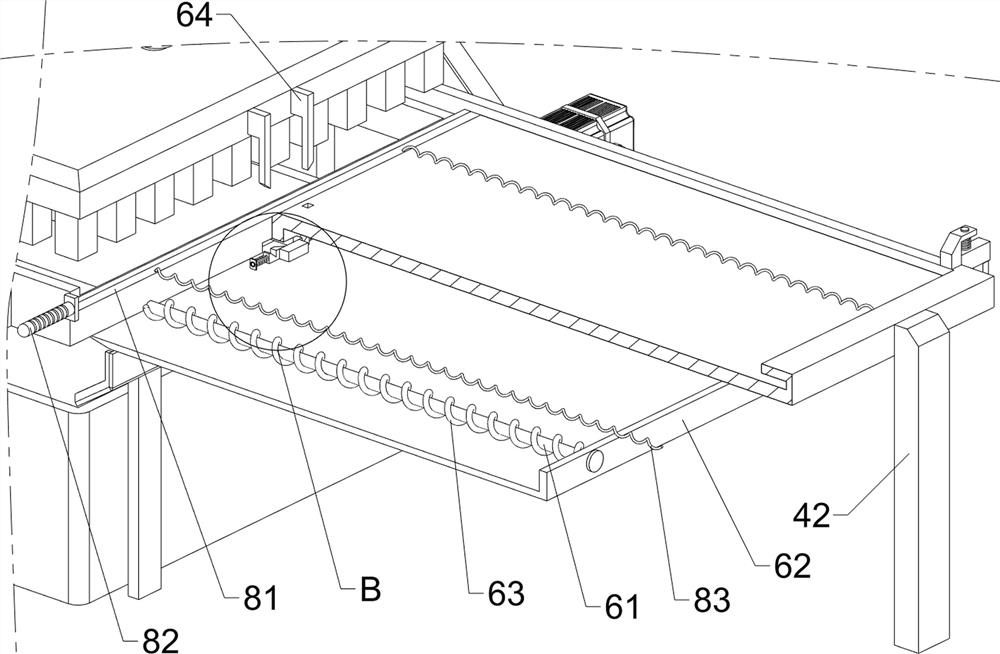

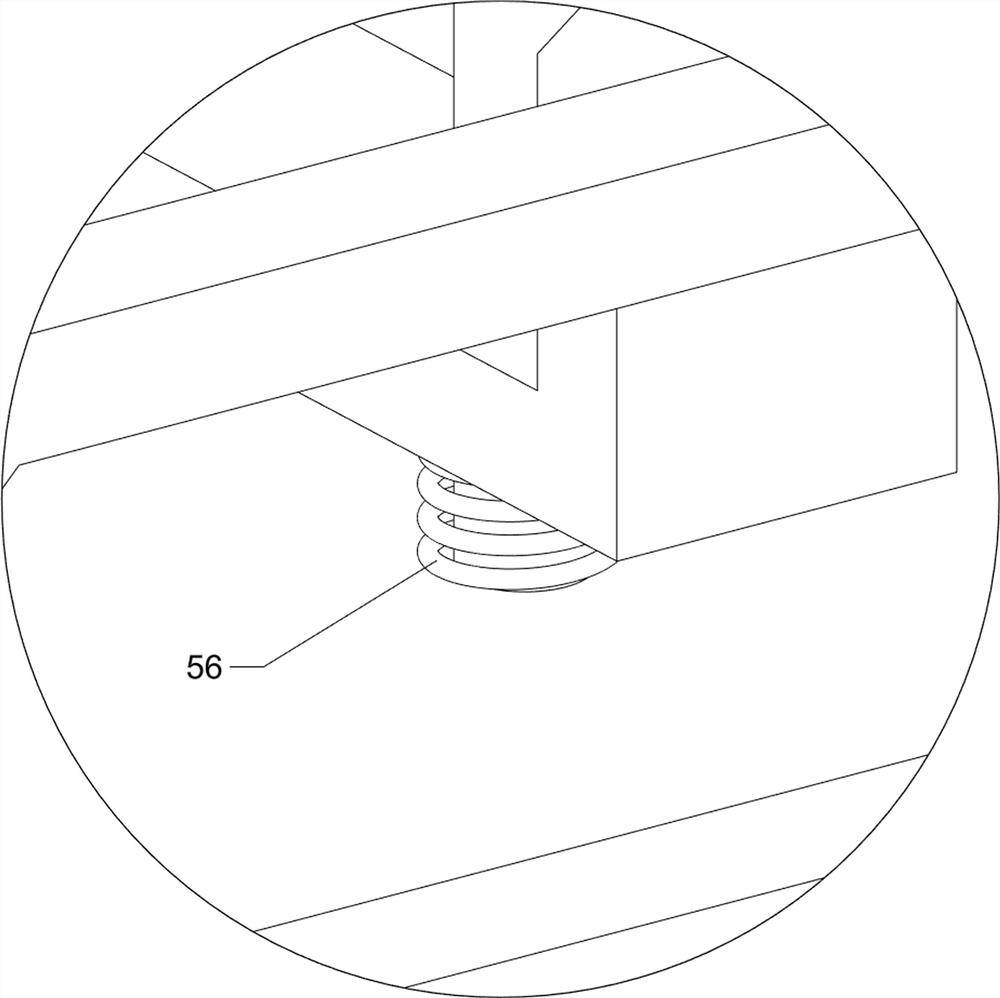

[0075] On the basis of Example 2, such as Figure 5-11 As shown, it also includes a scraping assembly 6, and the scraping assembly 6 includes a second guide rod 61, a scraper 62, a second spring 63, a first wedge block 64, a third guide rod 65, a second wedge block 66 and a second wedge block 66. Three springs 67, the front and rear sides of the middle part of the placement plate 43 are connected with a second guide rod 61, and a scraper 62 is slidably connected between the second guide rods 61, and the scraper 62 is slidably connected with the placement plate 43. The second spring 63 is connected between the side and the placement plate 43, and the second spring 63 is sleeved on the outside of the second guide rod 61. The front and rear sides of the left part of the pressing plate 55 are connected with the first wedge-shaped block 64, and the top of the right side of the scraper 62 Both front and rear sides are slidingly connected with a third guide rod 65, and the inside of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap