Dispensing compensation system and compensation method based on glue flow detection

A flow detection and compensation system technology, applied in the field of dispensing compensation, can solve the problems that the glue volume cannot be accurately weighed, the glue is easy to stick to the needle, and the weighing method is not ideal, so as to achieve stable compensation of glue, Good market application value, the effect of improving debugging efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

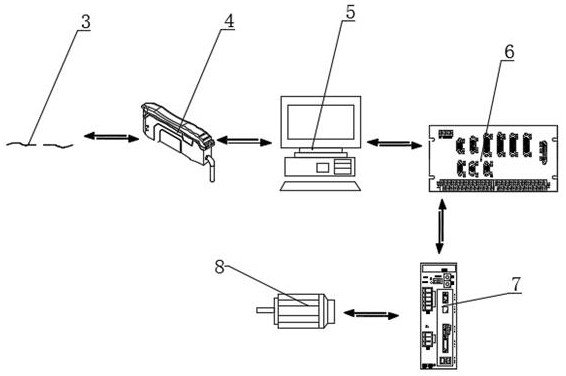

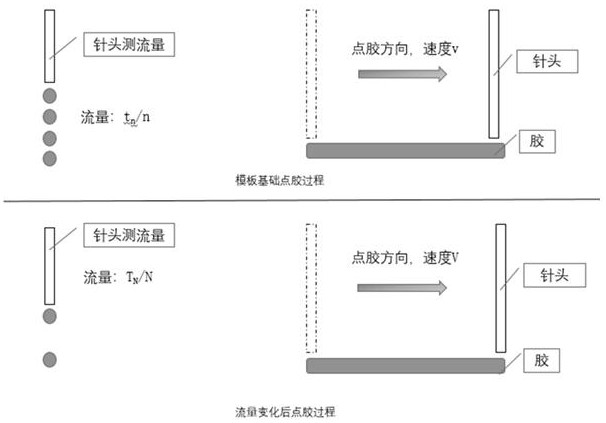

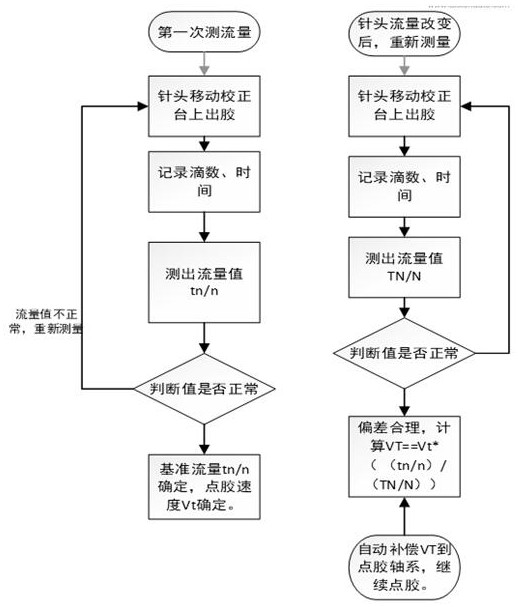

[0035] Such as Figure 1 to Figure 5 As shown, Embodiment 1 of the present invention: a dispensing compensation system based on glue flow detection, including a glue receiving mechanism, a fixing seat 1, an optical fiber sensor 3, an amplifier 4, a PC industrial computer 5, a driver 7 and dispensing execution Motor 8, the fixed seat 1 is arranged directly below the dispensing needle of the dispensing equipment, the material receiving mechanism is arranged at the middle and upper part of the fixed seat 1, and the optical fiber sensor 3 is arranged at the upper part of the fixed seat 1 And located directly above the material receiving mechanism, the optical fiber sensor 3 is connected to the amplifier 4 through a connecting line, the amplifier 4 is connected to the PC industrial computer 5 through a connecting line, and the PC industrial computer 5 is connected to the The driver 7 is connected through a connection line, the driver 7 is connected with the dispensing execution mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com