Electrode cooling structure and butt welding machine thereof

A cooling structure and electrode technology, applied in the direction of cooling electrodes, electrode characteristics, resistance welding equipment, etc., can solve the problems of low production efficiency of steel rings, unstable welding quality, troublesome alignment of steel ring gaps, etc., to achieve strong practicability and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

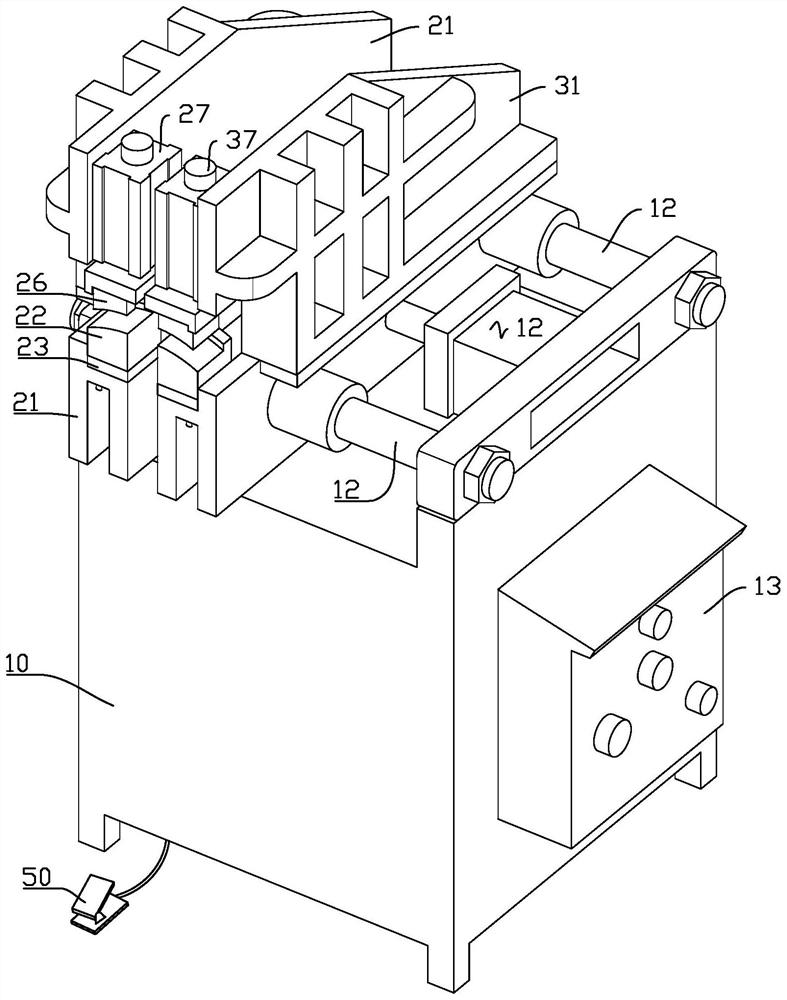

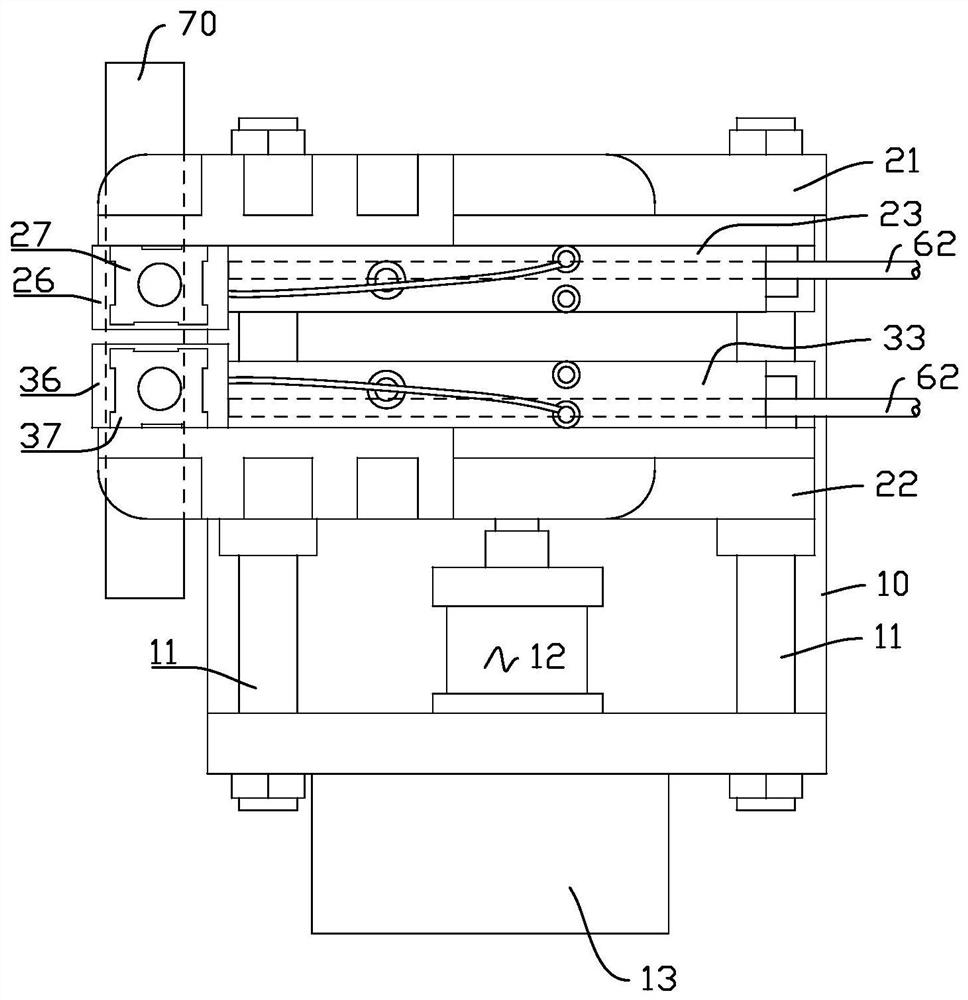

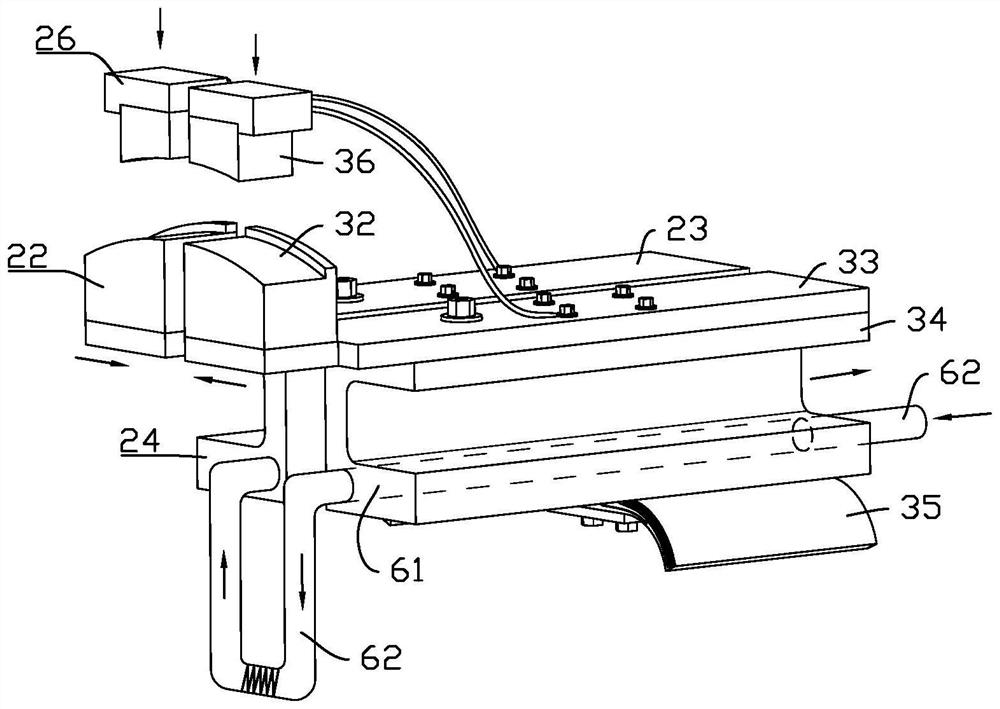

[0022] refer to Figure 1 to Figure 6 , the present invention discloses a butt welding machine, comprising a frame 10 as a bearing body, a pair of guide rods 11 arranged on the frame 10, a left mounting seat 21 and a right mounting seat 31 arranged on the guide rods 11, Several components on the left mounting base 21 and the right mounting base 31, power supply module, cooling module and control system.

[0023] Specific reference figure 1 , The frame 10 is in the shape of a cube as a whole, and the side of the frame 10 is provided with a control cabinet 13 for installing some switches and control systems. A pair of guide rods 11 are horizontally and parallelly arranged above the frame 10, and then the two guide rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap