Wood table leg cutting and forming equipment

A technology for forming equipment and tables, applied in sawing equipment, unloading equipment, sawing components, etc., can solve problems such as inaccurate cutting lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

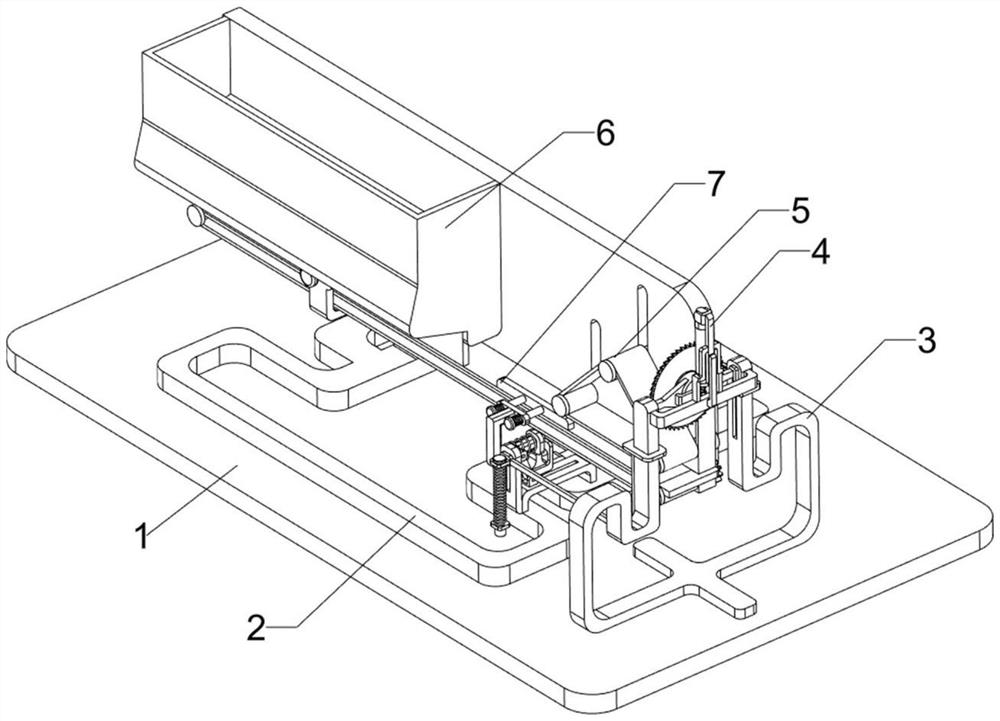

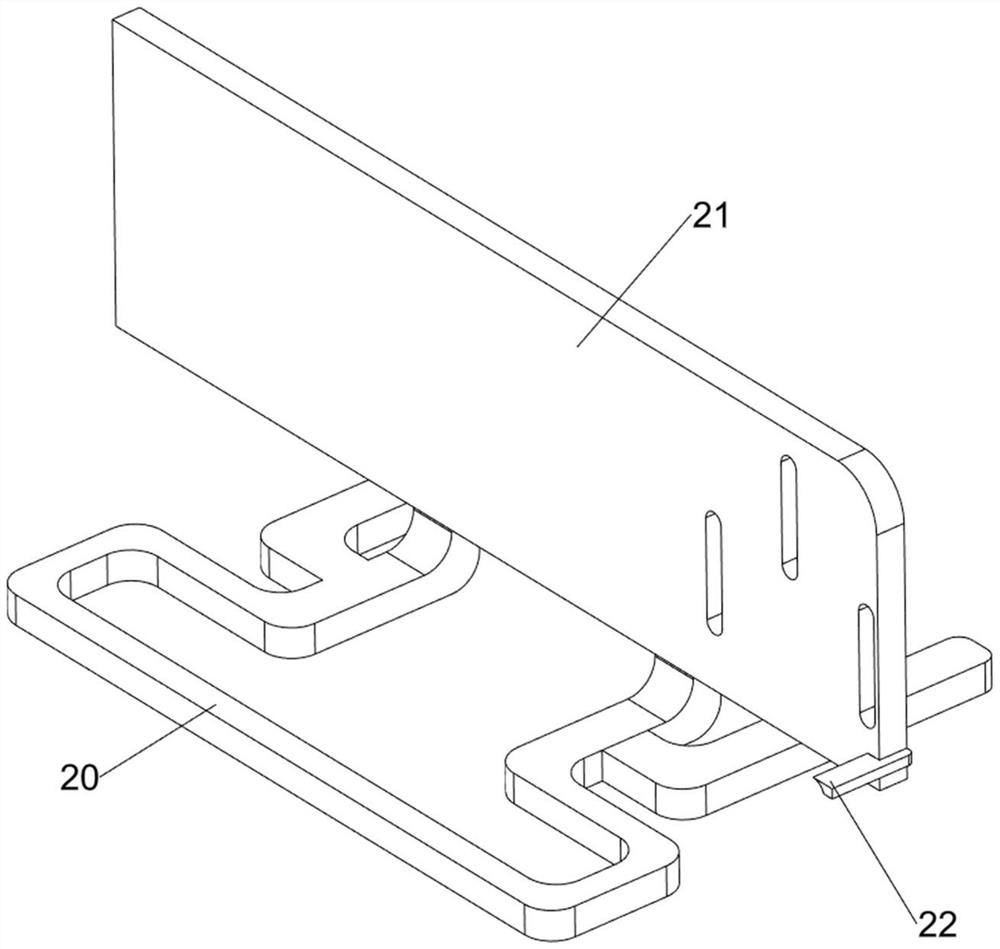

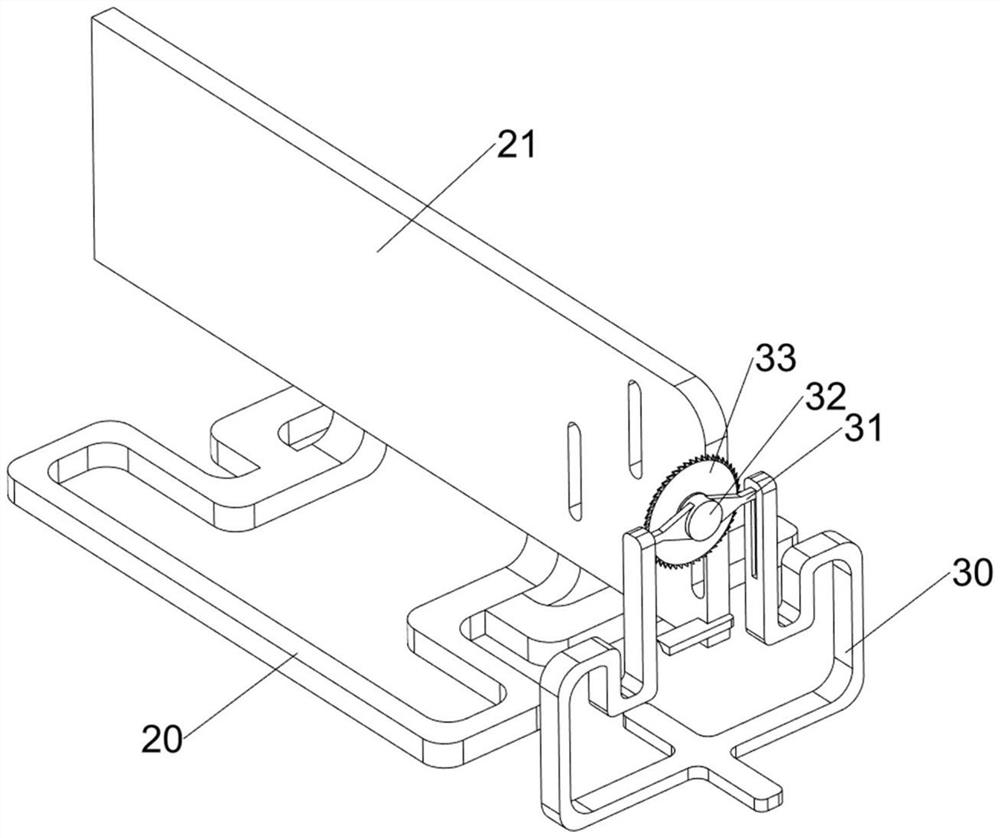

[0032] A kind of wooden table leg cutting molding equipment, such as figure 1 , figure 2 with image 3 As shown, it includes a base 1, a placing mechanism 2 and a sawing mechanism 3, the base 1 is provided with a placing mechanism 2, and the top right side of the base 1 is provided with a sawing mechanism 3.

[0033] When people need to use this device, first people will pull up the sawing mechanism 3, and place one end of the wooden block on the placement mechanism 2, so that the wooden block is located below the sawing mechanism 3, and then the sawing mechanism 3 can be started to make the saw Breaking mechanism 3 rotates, and then people move sawing mechanism 3 downwards, and sawing mechanism 3 cuts the block, and people move upwards sawing mechanism 3 when the cutting is completed, and people move the block to the right at the same time. A cut is prepared, so that the rapid cutting of the wood block can be realized by repeating it constantly. When people do not need to ...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11Shown, also comprise up and down mechanism 4, and up and down mechanism 4 comprises the 3rd installation frame 40, cylinder 41 and the second connection block 42, the right side of the second installation frame 30 top is provided with the 3rd installation frame 40, the 3rd mounting frame 40 A cylinder 41 is arranged on it, and a second connecting block 42 is arranged at the upper end of the telescoping rod of the cylinder 41, and the second connecting block 42 is connected with the first mounting block 31 .

[0039] After people place the planks, they can then start the servo motor 32 and the cylinder 41, and then control the cylinder 41 telescopic rod to move up and down, and the cylinder 41 telescopic rod drives the first mounting block 31 to move up and down through the second connecting block 42, so that it can be real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com