Floor fire-fighting vertical pipe construction installation mechanism and installation method

An installation mechanism and fire-fighting technology, which is applied to motor vehicles, lifting devices, mechanical equipment, etc., can solve the problems of damaged floor boards, high-quality fire-fighting pipes, and easy impact on floor boards, etc., and achieves the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

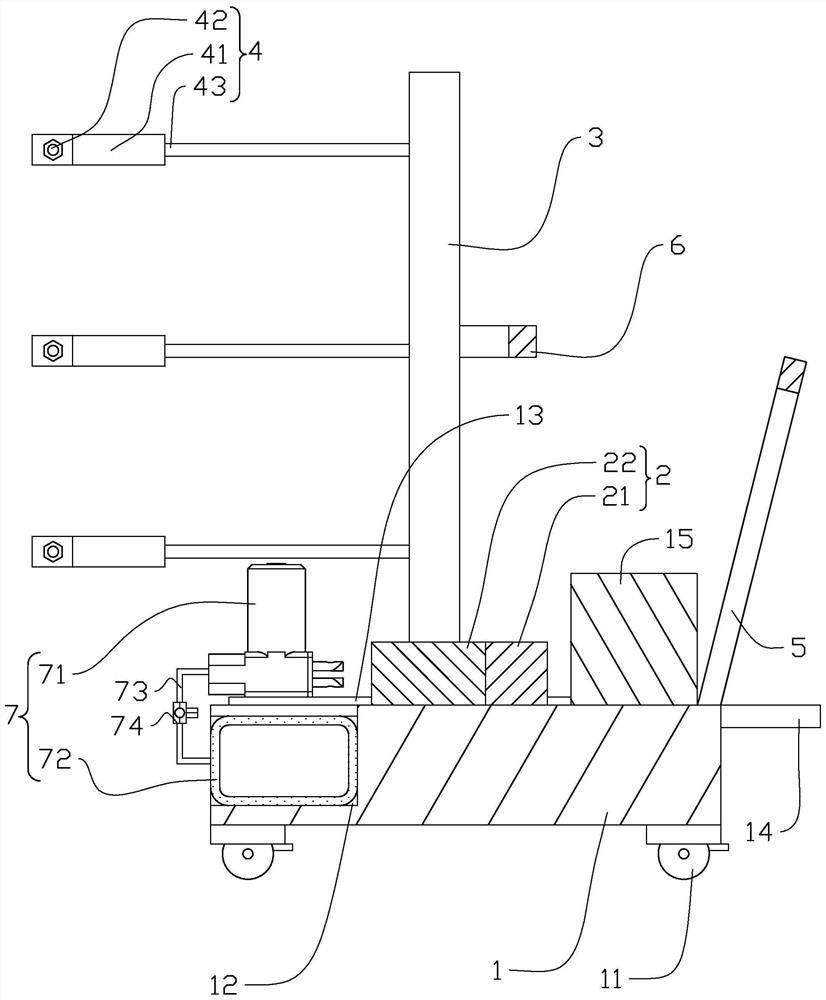

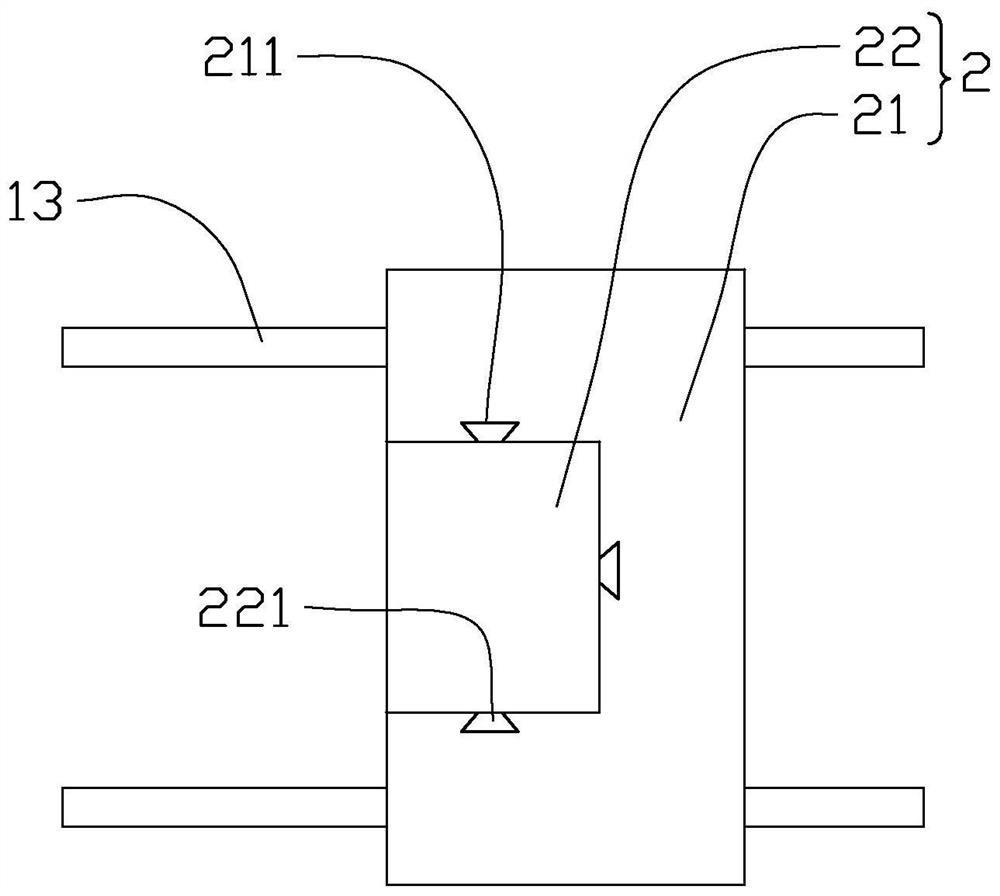

[0025] The following is attached Figure 1-2 The application is described in further detail.

[0026] The embodiment of the present application discloses a construction and installation mechanism for a fire riser in a floor. refer to figure 1 The construction and installation mechanism for the fire-fighting riser in the floor includes a car body 1, a mobile seat 2 arranged on the car body 1, a fixed column 3 vertically arranged on the mobile seat 2, and a fixed column for clamping the fire-fighting vertical pipe fixed with the fixed column 3. The clamping frame 4 of the pipe, the push armrest 5 fixed on the vehicle body 1 , the push handle 6 fixed on the fixed column 3 and the slowing device 7 arranged on the vehicle body 1 . The vehicle body 1 is in the shape of a rectangular seat, and four brake universal wheels 11 are fixedly installed on its bottom surface, and the four brake universal wheels 11 are respectively arranged at four corners of the bottom surface of the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com