A kind of co-ni-mn-si-tb giant magnetostrictive material and preparation method thereof

A co-ni-mn-si-tb, giant magnetostrictive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

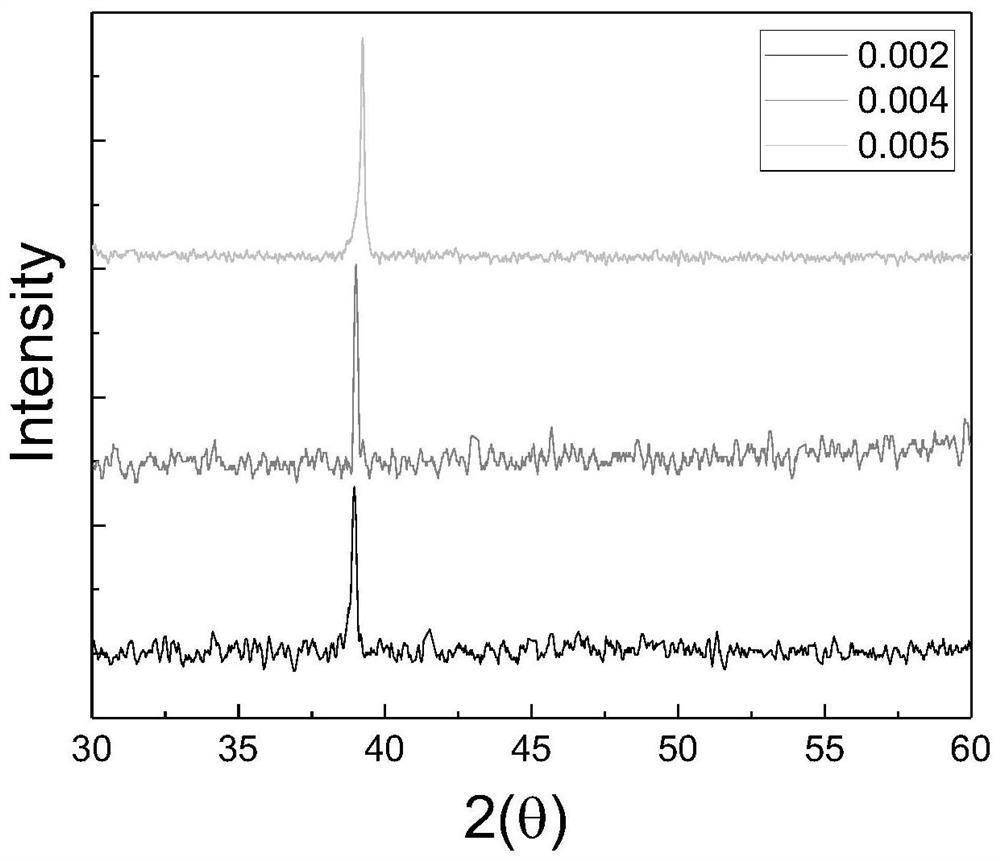

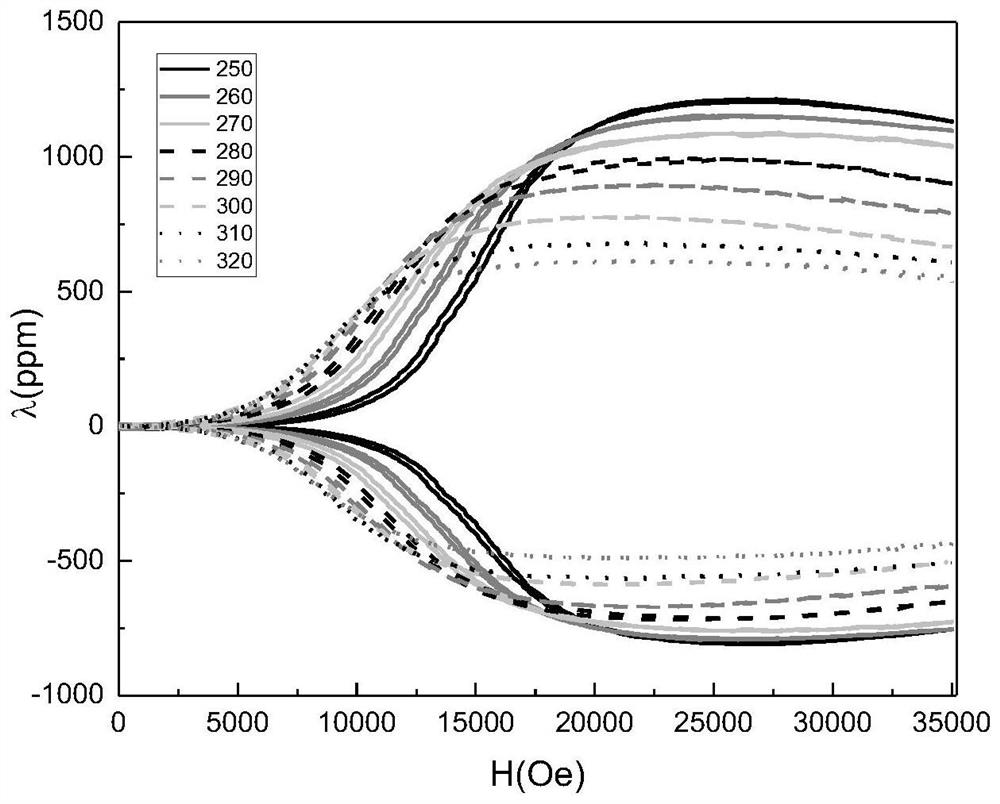

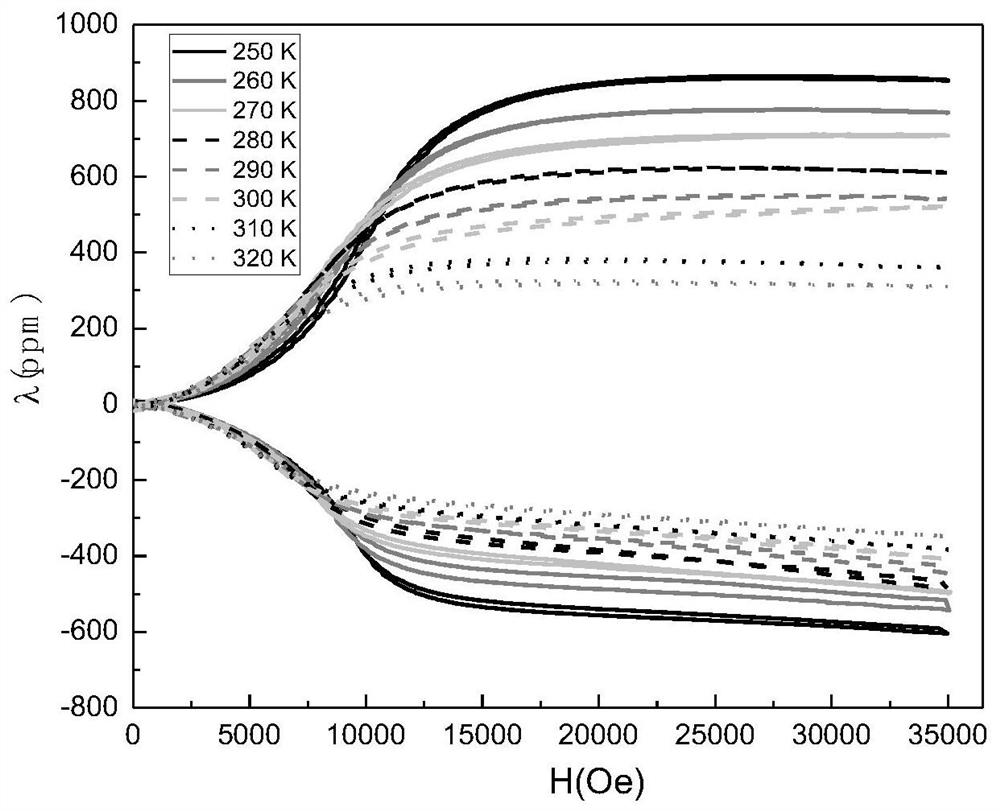

[0026] A Co-Ni-Mn-Si-Tb giant magnetostrictive material and a preparation method thereof, specifically implemented according to the following steps:

[0027] Step 1: Raw material ratio: according to the alloy chemical formula Co 0.97 Ni 0.03 MnSi (1-x) Tb x , x=0.002, take the Co, Ni, Mn, Si, Tb that take purity as 99.99%, carry out proportioning;

[0028] Step 2: Conventional vacuum arc melting: Put the elemental metals obtained by the ratio into the vacuum arc melting furnace, and place them according to the principle of higher melting point on top and lower melting point on the bottom; close the vacuum chamber, use mechanical pump and molecular pump Pull the vacuum in the chamber to 10 -5 Pa; filled with protective gas argon (ensure that the air pressure in the cavity is 0.06MPa to 0.09MPa lower than the atmospheric pressure); during the melting process, try to use a lower current, and ensure that the size of the melting current and the melting time of each group are eq...

Embodiment 2

[0033] A Co-Ni-Mn-Si-Tb giant magnetostrictive material and a preparation method thereof, specifically implemented according to the following steps:

[0034] Step 1: Raw material ratio: according to the alloy chemical formula Co 0.97 Ni 0.03 MnSi (1-x) Tb x , x=0.004, take the Co, Ni, Mn, Si, Tb that take purity as 99.99%, carry out proportioning;

[0035] Step 2: Conventional vacuum arc melting: Put the elemental metals obtained by the ratio into the vacuum arc melting furnace, and place them according to the principle of higher melting point on top and lower melting point on the bottom; close the vacuum chamber, use mechanical pump and molecular pump Pull the vacuum in the chamber to 10 -5 Pa; filled with protective gas argon (ensure that the air pressure in the cavity is 0.06MPa to 0.09MPa lower than the atmospheric pressure); during the melting process, try to use a lower current, and ensure that the size of the melting current and the melting time of each group are eq...

Embodiment 3

[0040] A Co-Ni-Mn-Si-Tb giant magnetostrictive material and a preparation method thereof, specifically implemented according to the following steps:

[0041] Step 1: Raw material ratio: according to the alloy chemical formula Co 0.97 Ni 0.03 MnSi (1-x) Tb x , x=0.005, take the Co, Ni, Mn, Si, Tb that take purity as 99.99%, carry out proportioning;

[0042] Step 2: Conventional vacuum arc melting: Put the elemental metals obtained by the ratio into the vacuum arc melting furnace, and place them according to the principle of higher melting point on top and lower melting point on the bottom; close the vacuum chamber, use mechanical pump and molecular pump Pull the vacuum in the chamber to 10 -5 Pa; filled with protective gas argon (ensure that the air pressure in the cavity is 0.06MPa to 0.09MPa lower than the atmospheric pressure); during the melting process, try to use a lower current, and ensure that the size of the melting current and the melting time of each group are eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetostriction | aaaaa | aaaaa |

| magnetostriction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com