Enamel firing bracket used for firing enamel ornaments

An enamel and jewelry technology, applied in the field of jewelry processing tools, can solve the problems of uneven shapes and sizes, waste of financial resources and space, and many shapes and specifications, so as to increase the scope of application, simple and easy operation, and safer. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

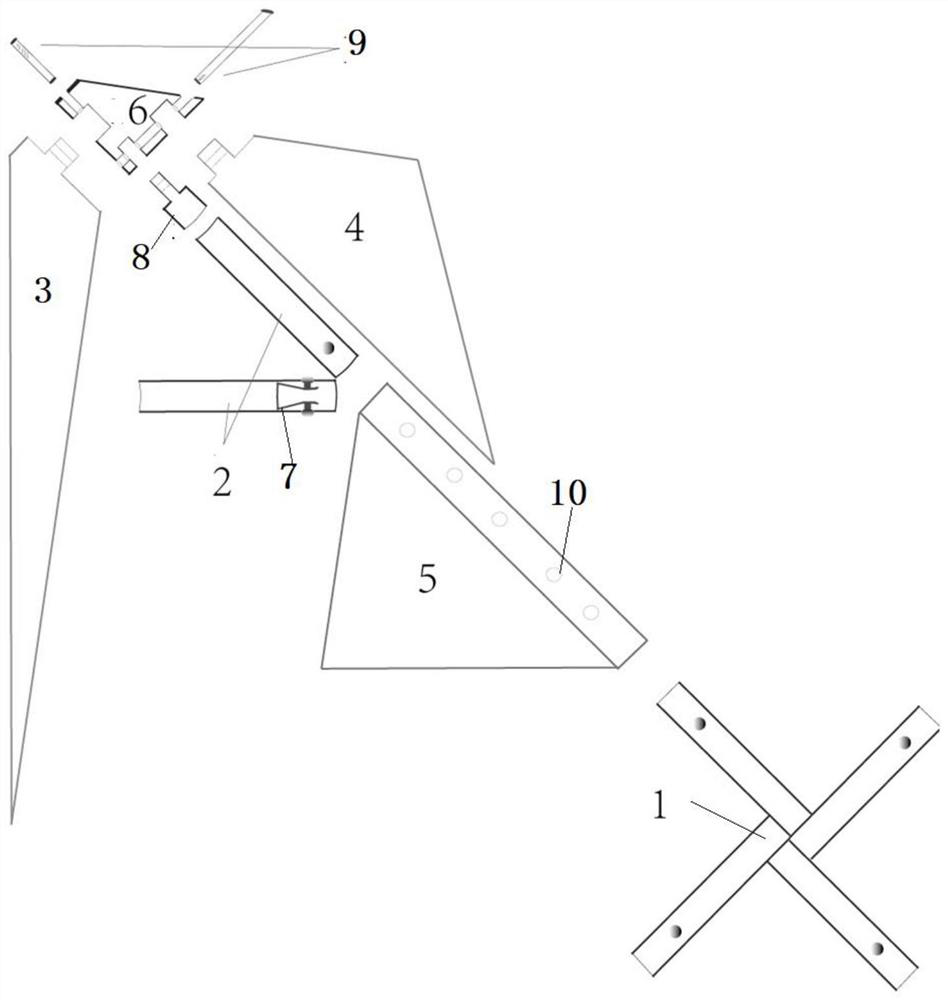

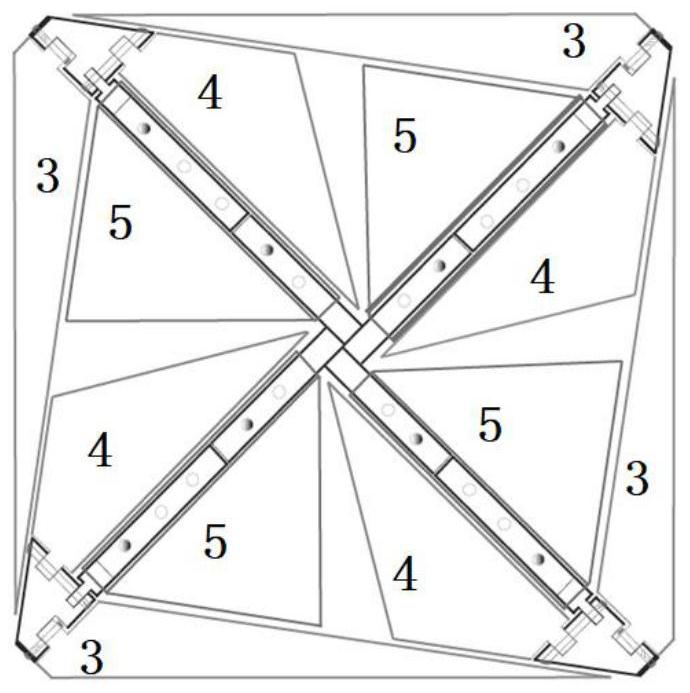

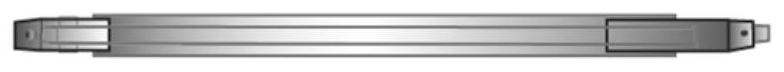

[0038] see Figure 1-3 , an enamel firing bracket for firing enamel ornaments in this embodiment, comprising: a central bracket 1, three layers of triangular brackets and angle irons 6, wherein the central bracket 1 forms a cross extending outward from the center The main shaft, the outer outline is square or rectangular, and the overall shape is square or rectangular; the triangular support is a structure that can be opened and closed, and can be flat or erected according to needs. The three-layer triangular support is fixed on the central support by folding. On the rack 1, the three-layer triangular support is an openable structure, which can be squared or erected according to needs. During use, the three-layer triangular support can be opened and closed according to needs, and folded into a plane after use, which saves space and does not have to be tied. Risk of injury; the angle iron 6 is used to connect the center bracket 1 and the three-layer triangular bracket, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com