High-precision vibration absorber

A shock absorber, high-precision technology, applied in the functional characteristics of spring/shock absorber, spring/shock absorber, vibration suppression adjustment, etc., can solve the problem of mass component adjustment step size, difficulty in meeting precise frequency modulation, and non-adjustable spring stiffness and other issues, to achieve the effect of improving cross-section utilization, compact structure, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

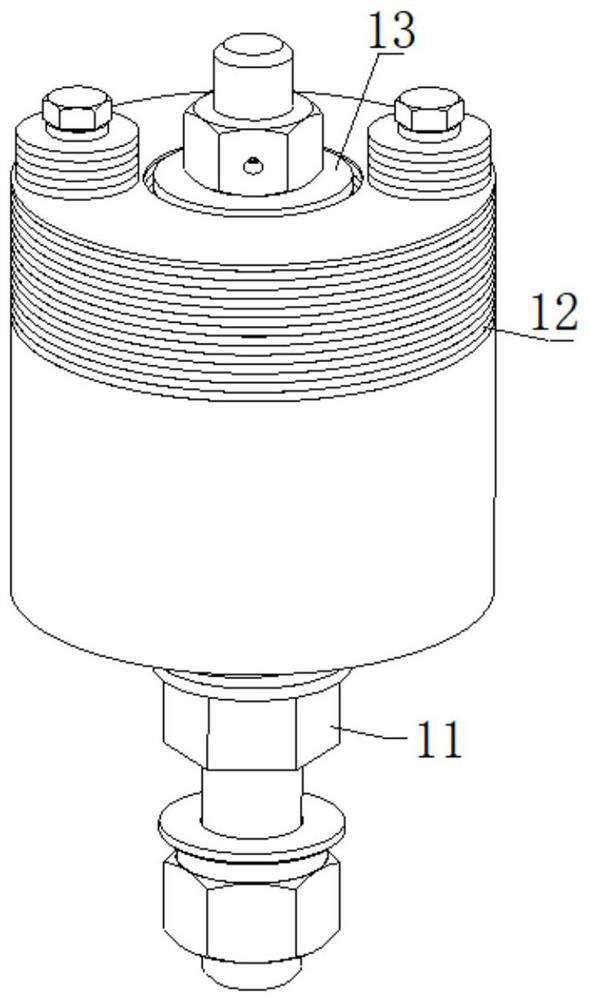

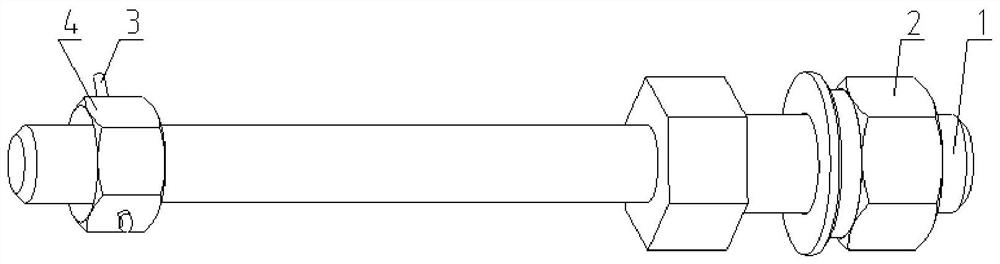

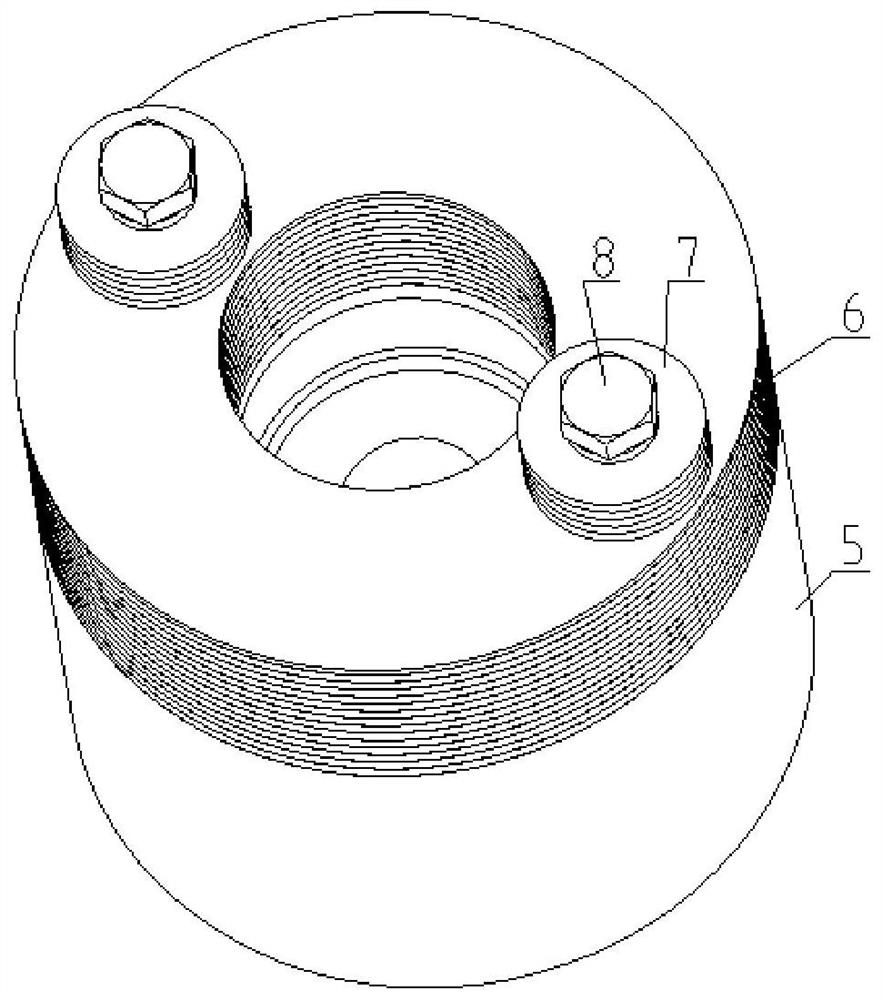

[0033] Such as figure 1 As shown, the shock absorber includes: a support assembly 11, a mass assembly 12 and an elastic assembly 13; as figure 2 As shown, the support assembly 11 includes: a guide rod 1, a threaded fastener I2, a positioning pin 3 and a positioning nut 4; as image 3 As shown, the mass assembly 12 includes: a mass block 5, a mass sheet 6, a mass pad 7 and a threaded fastener II 8; as Figure 4 As shown, the elastic component 13 includes: a positioning cylinder 9 and a spring 10; wherein, each component of the shock absorber in this embodiment is made of metal (mass 5, mass sheet 6 and mass pad 7 are made of steel), which has performance Stability, high and low temperature resistance, anti-corrosion and anti-rust, radiation resistance, oil resistance.

[0034] The connection relationship of the shock absorber is: the elastic assembly 13 clamps the mass assembly 12 in the middle for shock absorption, the elastic assembly 13 is fixed on the support assembly 11...

Embodiment 2

[0048] On the basis of Embodiment 1, the materials of mass block 5, mass sheet 6, and mass pad 7 can be changed from steel to copper with a higher density. In this way, the size of mass element 11 can be further reduced to make vibration absorption The device is more compact.

Embodiment 3

[0050] On the basis of Embodiment 1 or 2, the mass pad 7 can be changed to a standard flat washer to reduce manufacturing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com