Valve combination structure with front pressure reducer

A combined structure and pressure reducer technology, applied in the aerospace field, can solve problems such as launch mission failure and easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

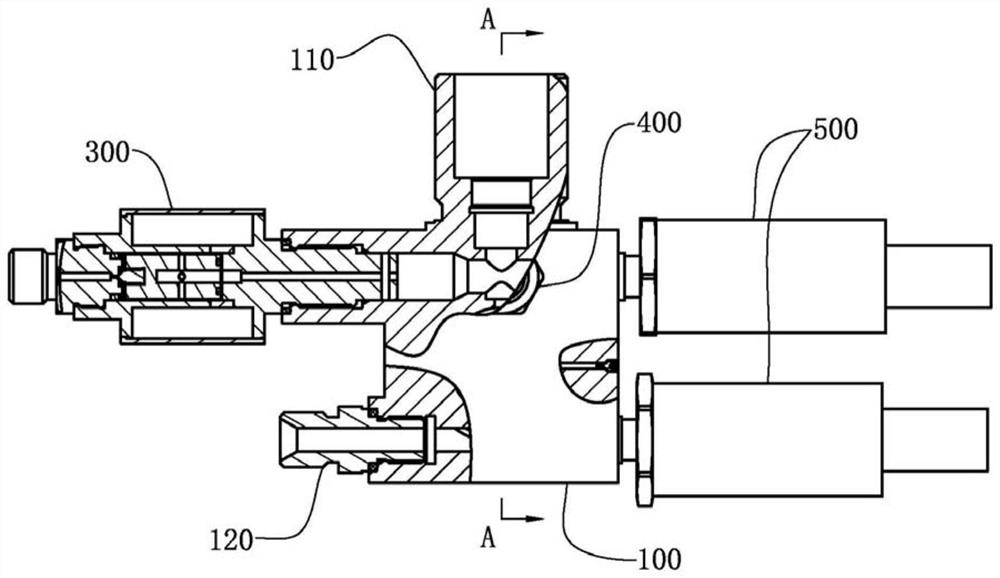

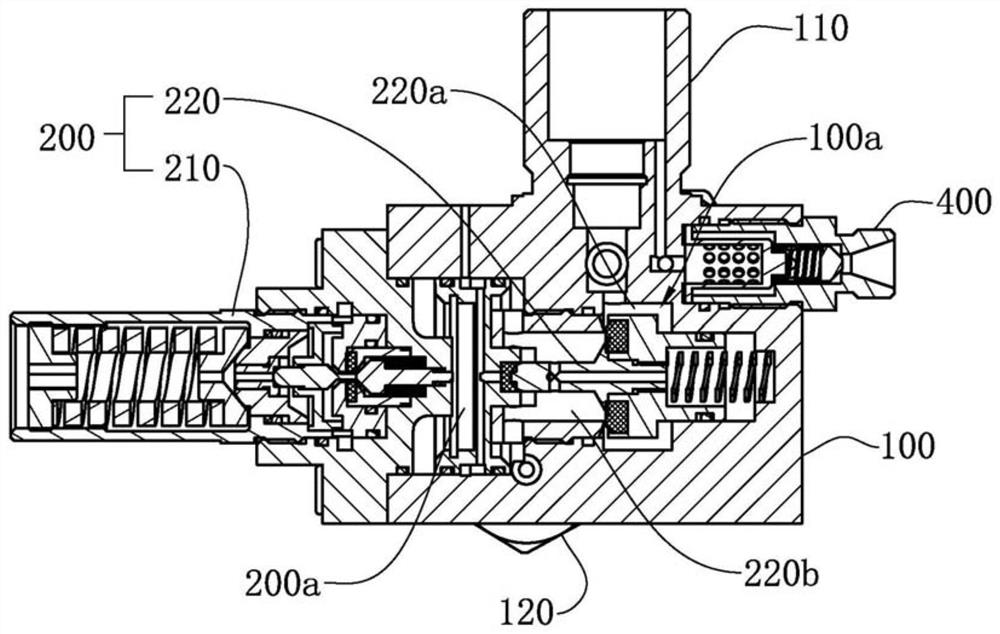

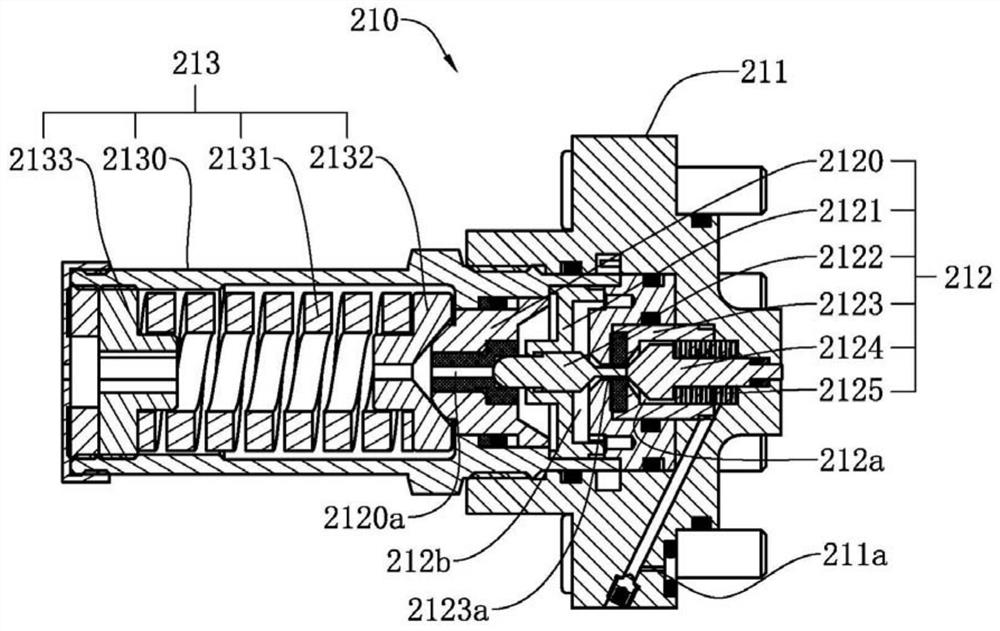

[0057] see Figure 1 to Figure 7 , the present embodiment provides a pressure reducer in front of the valve combination structure, which is applied to the extrusion conveying system of the rocket engine. Through the integrated combination method, the welding structure is reduced, and the installation process of the gas pipeline valve is improved. Improve the reliability of the system.

[0058] The rocket engine extrusion conveying system also includes a gas cylinder and a storage tank. The gas cylinder and the storage tank are connected by a valve combination structure in front of the pressure reducer. The gas cylinder is used to provide gas, and the valve combination in front of the pressure reducer The structure is used to control the output gas pressure of the gas cylinder, and then control the pressure of the air pillow of the storage tank.

[0059] Please refer to figure 1 and figure 2 The combined structure of the pressure reducer provided in this embodiment includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com