Capacitance calibration effect evaluation method and system

A technology of capacitance and calibration points, which is applied in the field of evaluation of capacitance calibration effects, can solve problems such as large electromagnetic interference of machine tools, plate movement, poor grounding, etc., and achieve the effect of easy decision and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

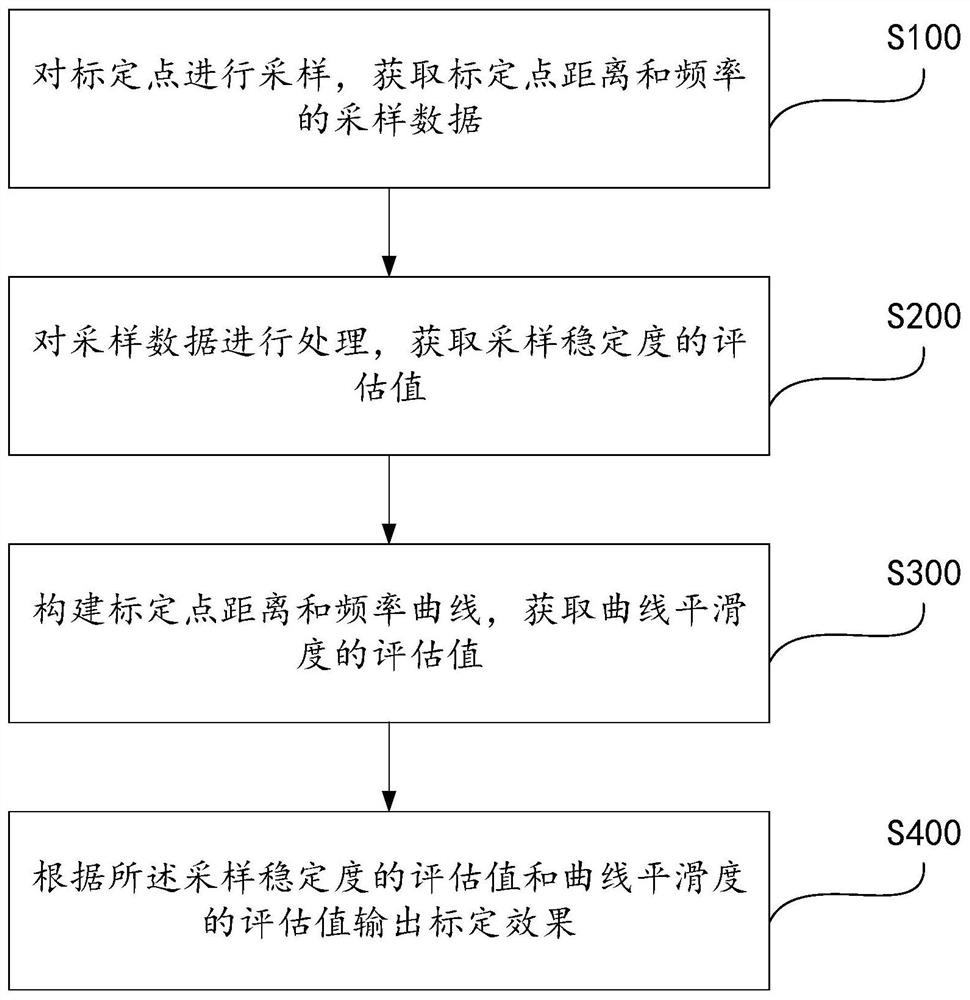

[0077] A method for evaluating the effect of capacitance calibration, such as figure 1 shown, including the following steps:

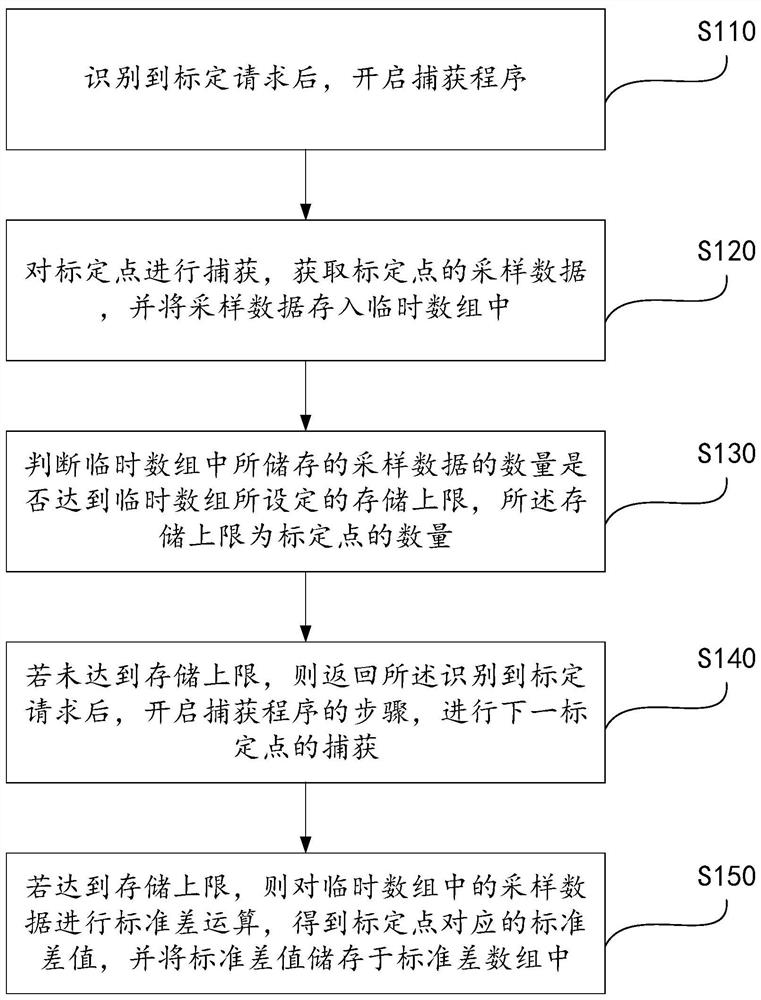

[0078] S100: Sampling the calibration point to obtain sampling data of calibration point distance and frequency;

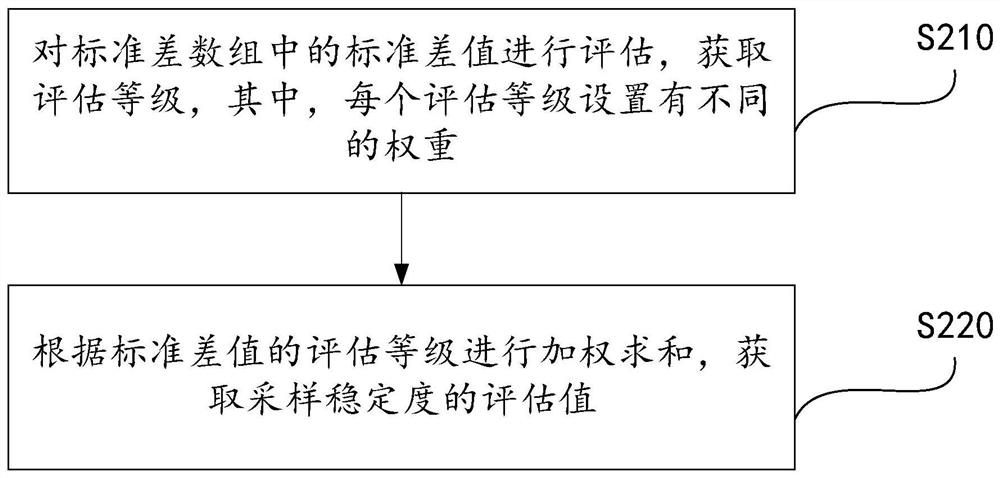

[0079] S200: Process the sampling data to obtain an evaluation value of sampling stability;

[0080] S300: Construct calibration point distance and frequency curve, obtain the evaluation value of curve smoothness;

[0081] S400: Output a calibration effect according to the evaluation value of the sampling stability and the evaluation value of the curve smoothness.

[0082] The evaluation method of the capacitance calibration effect provided by the embodiment of the present application obtains the sampling data of the calibration point in the calibration program, obtains the evaluation value of the sampling stability according to the sampling data, and then constructs the distance and frequency curve of the calibration point according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com