Radiation self-shielding industrial online CT

A radiation shielding and self-shielding technology, applied in shielding, material analysis using wave/particle radiation, nuclear engineering, etc., can solve problems such as conflict, small size, and self-shielding devices can only be detected offline, to improve detection efficiency, The effect of flexible application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

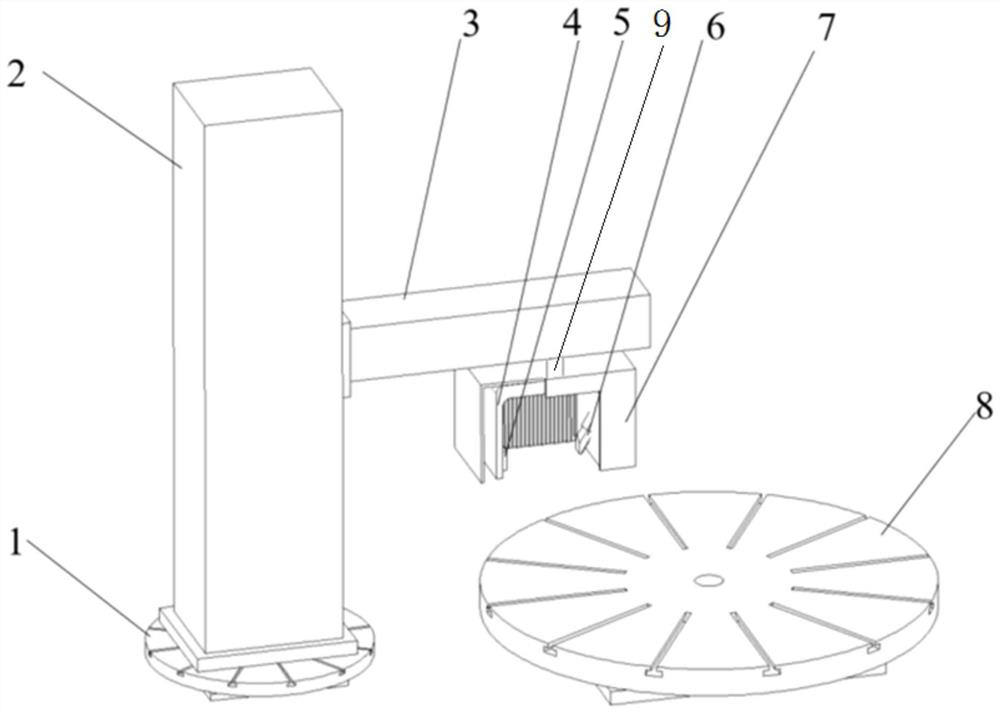

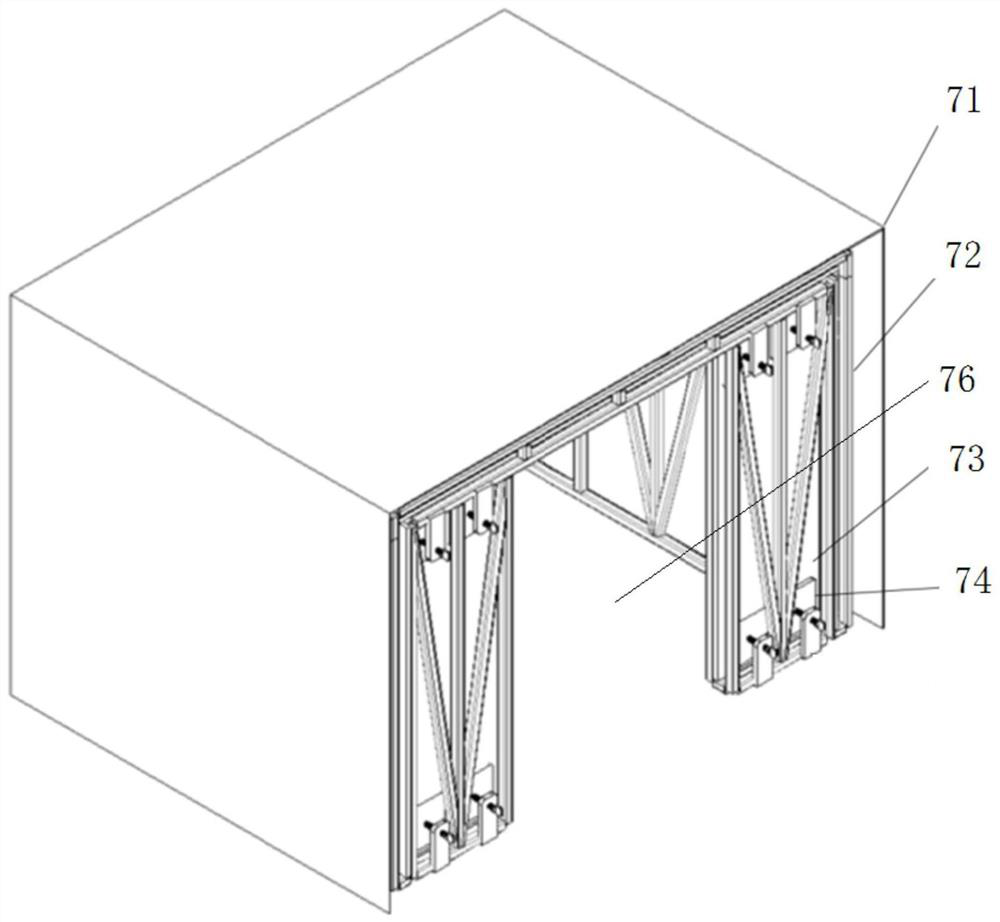

Embodiment 1

[0053] Such as Image 6 It is shown that the radiation self-shielding industrial online CT of the present invention can detect defects in the additive manufacturing process online. In this embodiment, the object 10 to be tested is a large ring-shaped part, and the detection system composed of the mounting bracket 4, the detector 5, the radiation source 6 and the radiation shielding chamber 7 moves to a large On the top of the ring part, different magnification ratios can be realized through the radial movement of the crossbeam 3, and an appropriate magnification ratio is selected according to the actual situation for detection. At this time, the printing head 11 performs the arc additive manufacturing process, and the large ring part It is driven to make a uniform rotational movement, so that part of the newly formed part enters between the detector 5 and the ray source 6 for detection. Since the detection system can only partially scan large ring parts, the rotating mechanism...

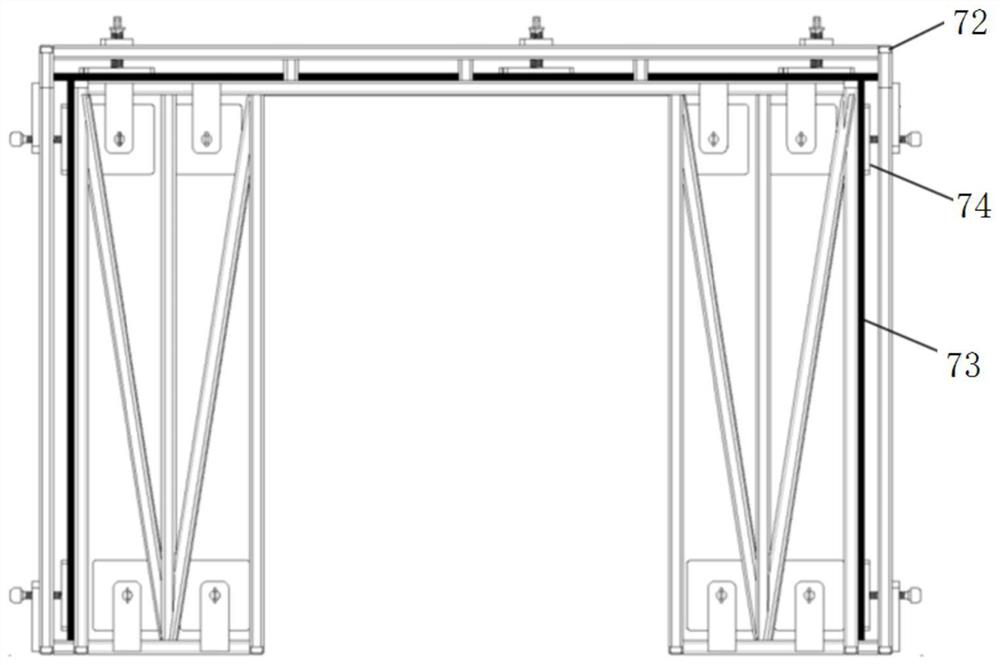

Embodiment 2

[0055] Such as Figure 7 It shows that the radiation self-shielding industrial online CT of the present invention can detect the defects in the additive manufacturing process offline. In this embodiment, the object 10 to be tested is a large ring-shaped part, and the detection system composed of the mounting bracket 4, the detector 5, the radiation source 6, and the radiation shielding chamber 7 runs to the circular shape under the drive of the column turntable 1, the column 2, and the beam 3. On the top of the part, different magnification ratios can be realized through the radial movement of the beam 3. After selecting a suitable magnification ratio for detection according to the actual situation, the detection starts from the bottom end of the ring part, and the workpiece turntable 8 drives the ring part to rotate at a constant speed. One week, at the same time the detector 5 and the ray source 6 complete a week of detection. After completing the industrial CT scan of the f...

Embodiment 3

[0057] Such as Figure 8 It is shown that the radiation self-shielding industrial on-line CT of the present invention performs off-line detection of small parts. Driven by the column turntable 1, column 2, and beam 3, the installation bracket 4, the detector 5, the radiation source 6, and the radiation shielding chamber 7 are located above the parts to be measured as a whole, and make the parts to be measured as a whole in the cone of the radiation source 6. Within the range of the X-ray beam, the radial movement on the crossbeam 3 combined with the rotational movement of the detection system ensures that the part to be tested is within the range of the X-ray cone beam, the ray source 6 and the detector 5 are turned on, and the workpiece turntable 8 drives the part to be tested to perform a rotational movement. The entire test is completed after one week of scanning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com