A muffler assembly

A muffler and assembly technology, which is applied in the field of auto parts, can solve the problems that the verification test is difficult to achieve, and the muffler assembly does not have adjustability, etc., so as to facilitate the change of noise cancellation ability and flow resistance, and a wide range of motion , verify the effect of work convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

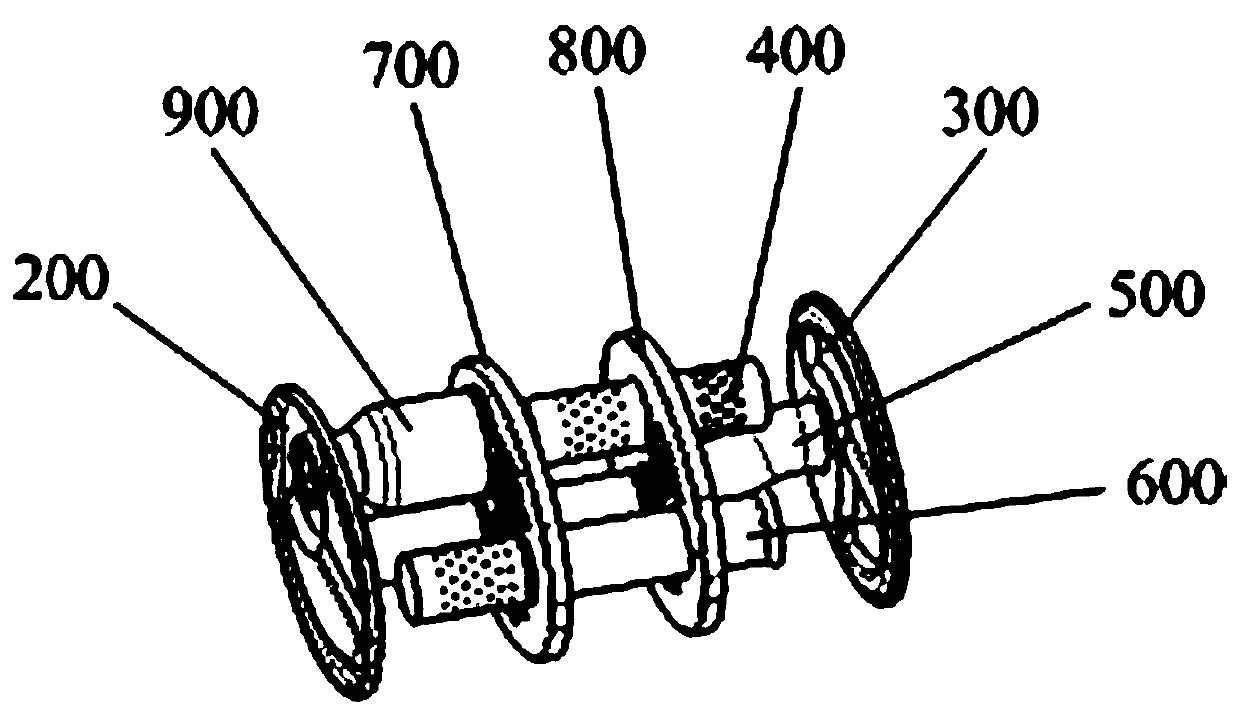

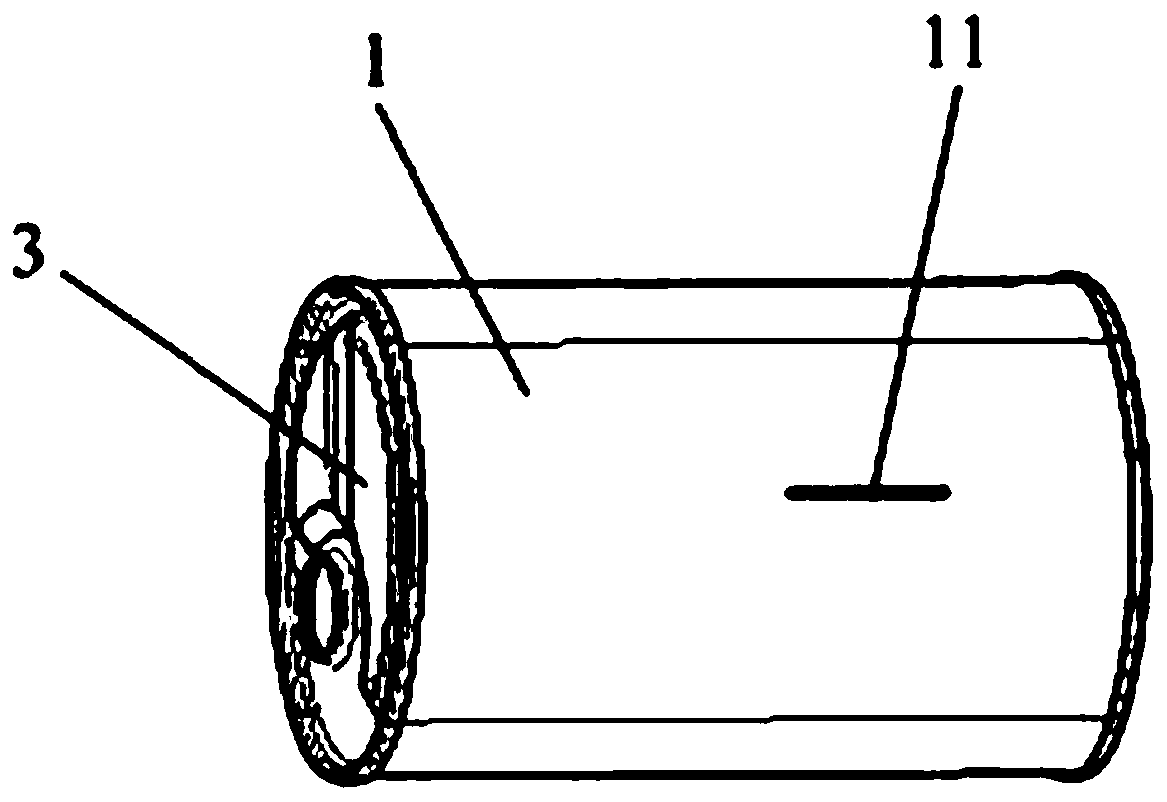

[0033] Such as Figure 3-Figure 5 As shown, the embodiment of the present invention provides a muffler assembly, including a housing 1, a first bottom plate 2, a second bottom plate 3, a first partition 4 and an auxiliary plate 5; the housing 1 is open at both ends Cylindrical structure, the first bottom plate 2 and the second bottom plate 3 are arranged at both ends of the housing 1 and form a cavity with the housing 1, the first partition plate 4 and the auxiliary The board 5 is arranged in parallel in the cavity and separates the cavity, and the sub-board 5 is slidably connected with the inner wall of the housing 1; the first partition 4 is provided with a through hole 6, so that The through hole 6 is provided with an elastic diaphragm, and the elastic diaphragm is provided with a slit; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com