Robot-based gas meter smart verification system and method

A gas meter and robot technology, which is applied to instruments, measuring devices, testing/calibration devices, etc., can solve the problems of many verification steps, time-consuming and laborious, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

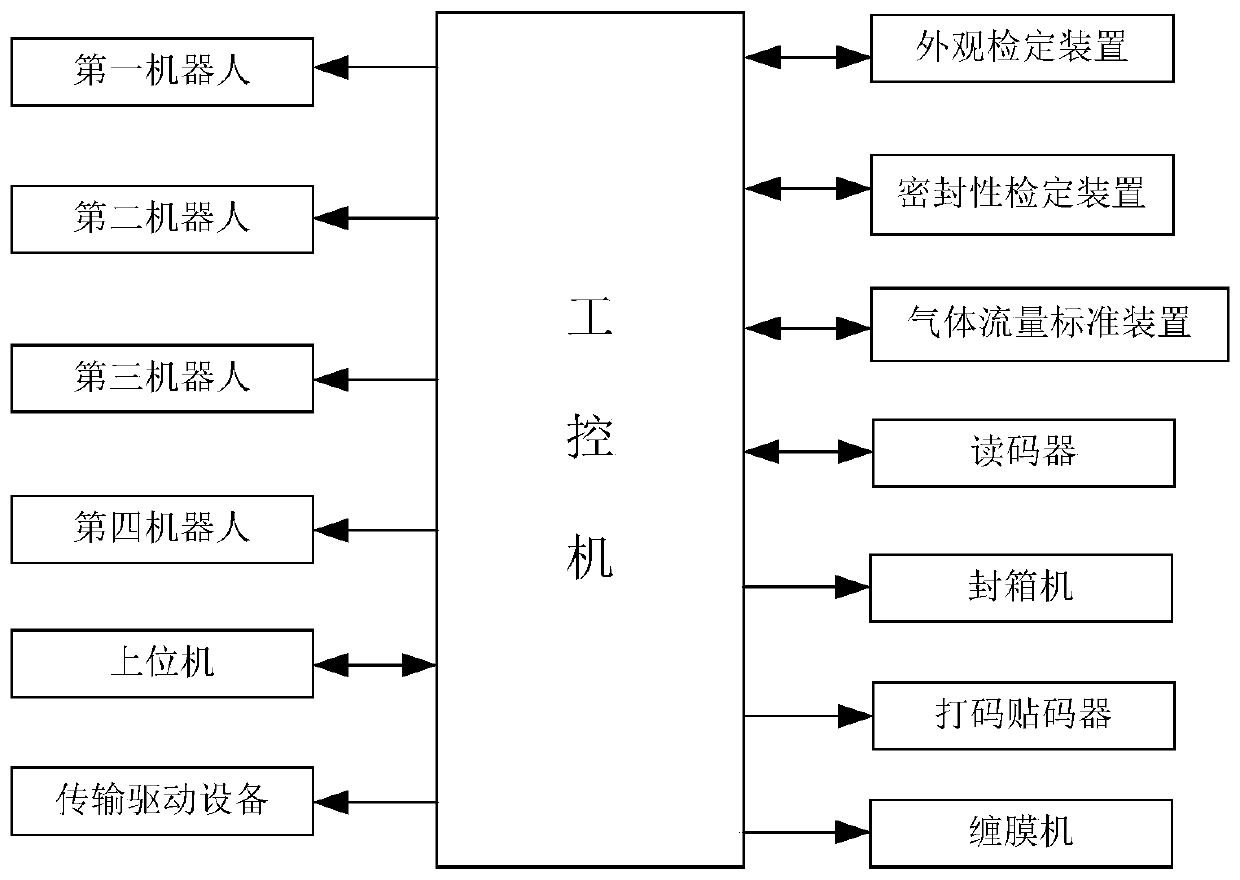

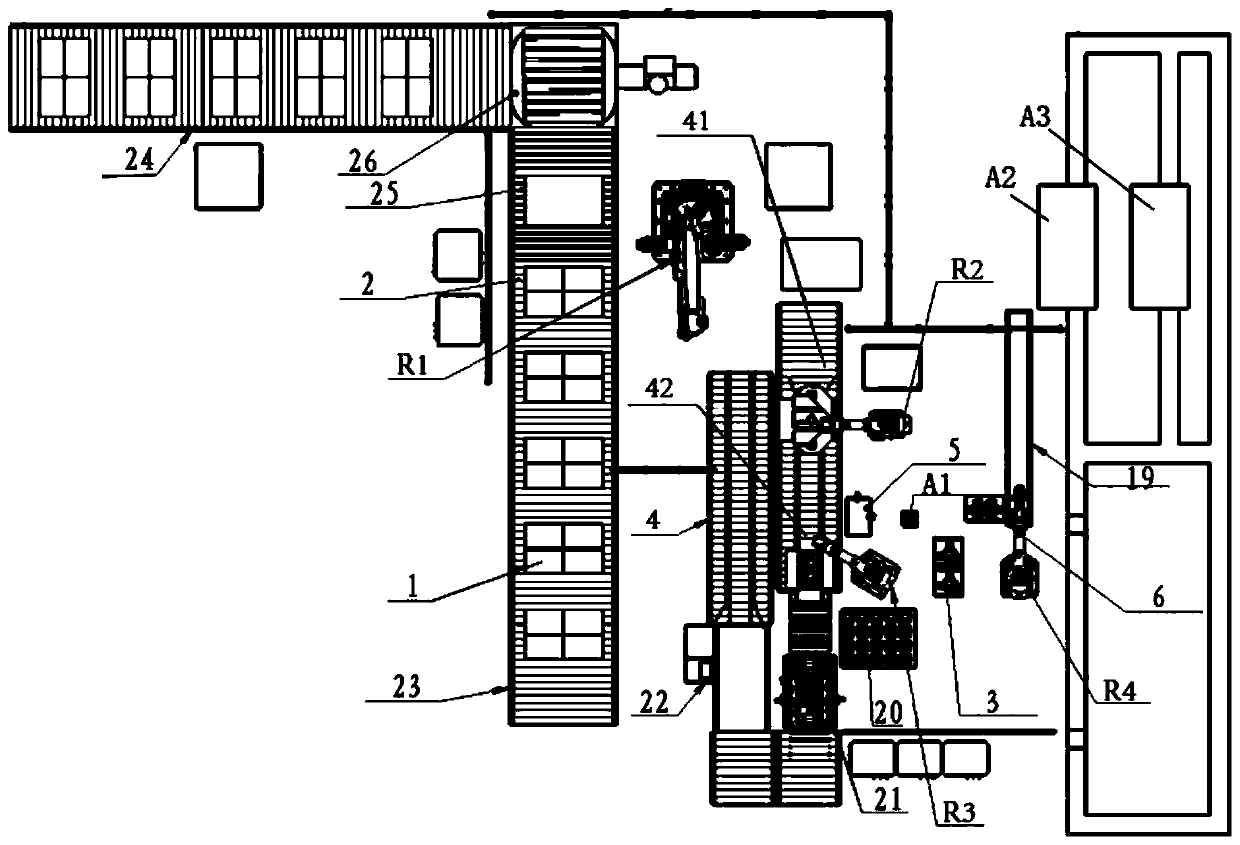

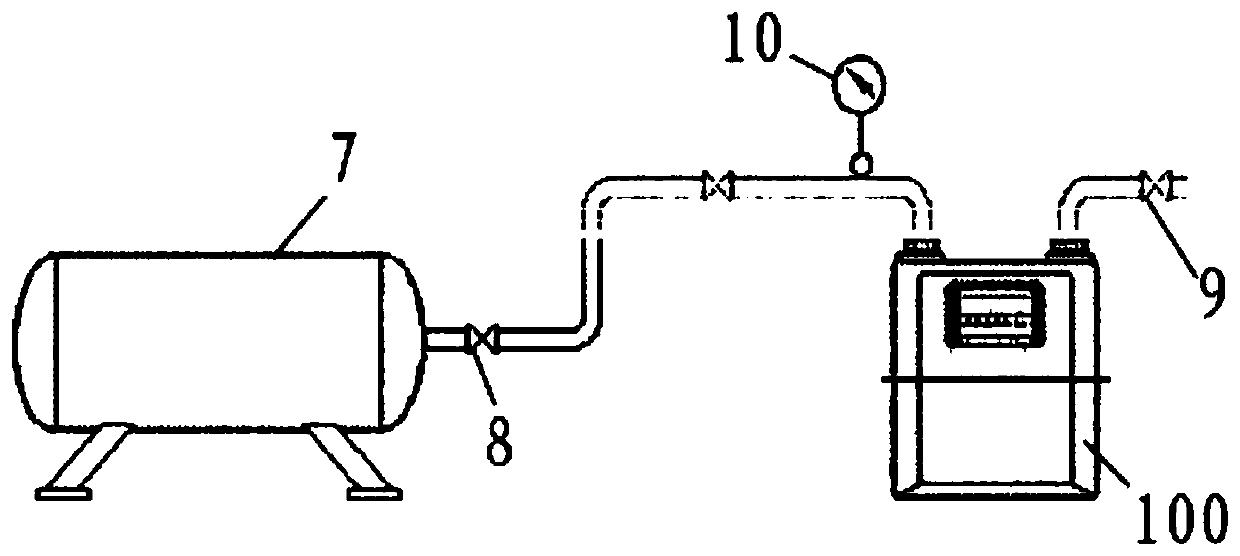

[0068] The invention discloses a smart verification system for gas meters based on robots, such as figure 1 and figure 2 As shown, it includes: industrial computer, unstacking station 2 for placing palletizing materials 1, transmission line 4, cover opening positioning platform 3, verification station, and the first robot R1, the second robot R2, and the third robot R3 and the fourth robot R4. The transmission driving device of the transmission line is connected to the industrial computer, and the transmission work is controlled by the industrial computer. The transmission line is sequentially provided with an unpacking station 41 and a picking / packing station 42 along the transmission direction. The verification station includes the appearance verification platform A1 and the sealing and flow verification tooling platform.

[0069] The first robot, the second robot, the third robot and the fourth robot are respectively connected to the industrial computer, and the industri...

Embodiment 2

[0130] The present invention discloses a gas meter smart verification method based on the robot-based gas meter smart verification system described in Embodiment 1, such as Figure 5 As shown, the steps are as follows:

[0131] Step S1, the industrial computer sends a control command to the first robot, and the first robot transports each box body equipped with a gas meter in the unstacking station to the front end of the transmission line.

[0132] Step S2, the industrial computer sends a control command to the second robot, and when each box moves to the unpacking station following the transmission line, the box is unpacked by the second robot.

[0133] Step S3, the industrial computer sends a control command to the third robot, and when each box moves to the picking / packing station following the transmission line, the gas meter in the box on the picking / packing station is transported to the verification station by the third robot On the appearance inspection platform of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com