Calibration device and method for checking operating speed of elevator speed limiter

A technology of elevator speed limiter and action speed, applied in the directions of transportation, packaging, elevators, etc., can solve the problems of low precision, complicated operation, low verification efficiency, etc., and achieve the effect of improving work efficiency, wide application prospect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] This embodiment uses Samsung's S3C6410X (ARM11) embedded microprocessor as the data processing module and the APC220-43 module as an example to illustrate the following.

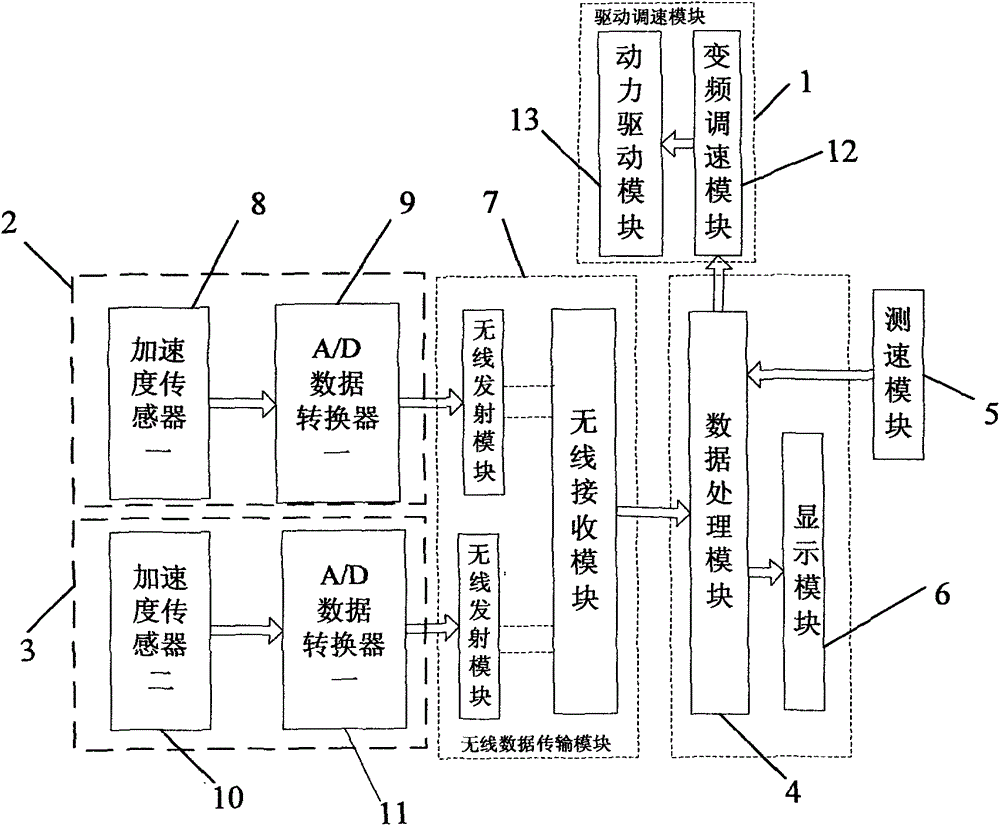

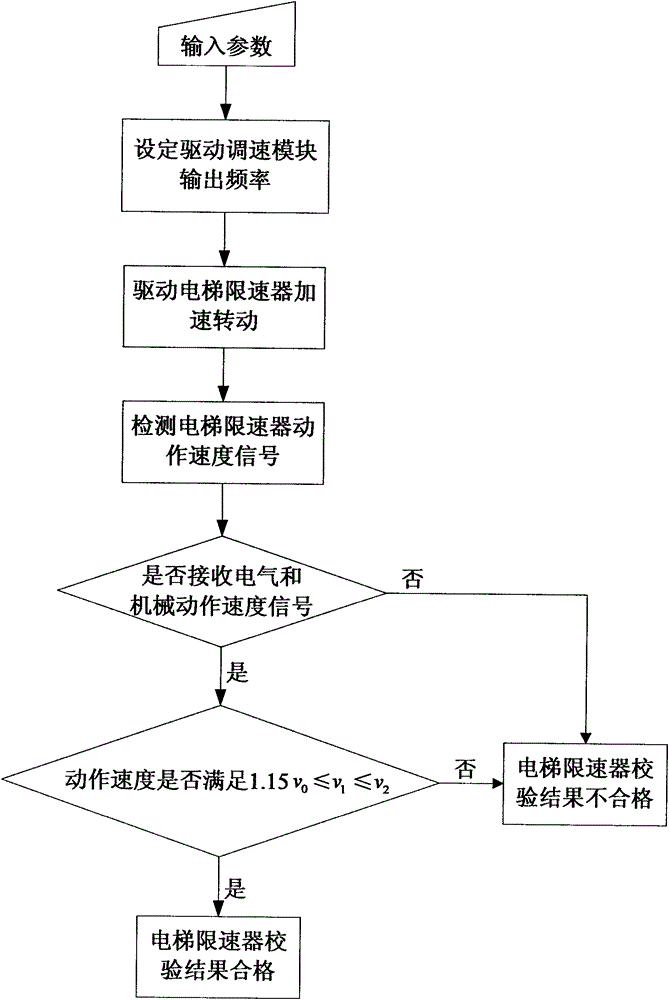

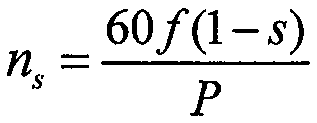

[0053] The module structure diagram of the elevator speed limiter action speed verification device of the present invention is as follows figure 1 As shown, the verification device includes a drive speed regulation module 1 for driving the elevator speed governor sheave to rotate; an electrical action detection module 2 for detecting the electrical action signal of the elevator speed governor; The mechanical action detection module 3 of the action signal; the data processing module 4 for receiving the signals of the electrical action detection module 2 and the mechanical action detection module 3 in real time and controlling the drive speed regulation module 1; the speed measurement module 5 connected with the data processing module 4 signal , to measure the rotation speed of the elevator speed govern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com