Portable Automatic Calibrator

A calibrator and portable technology, applied in the field of checking the tipping bucket rain sensor, can solve the problems of uncontrollable rain intensity, inability to simulate rain intensity, inconvenient to carry, etc., to eliminate interference factors and the possibility of misoperation ,Convenient for checking and verification work, the effect of comprehensive software functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

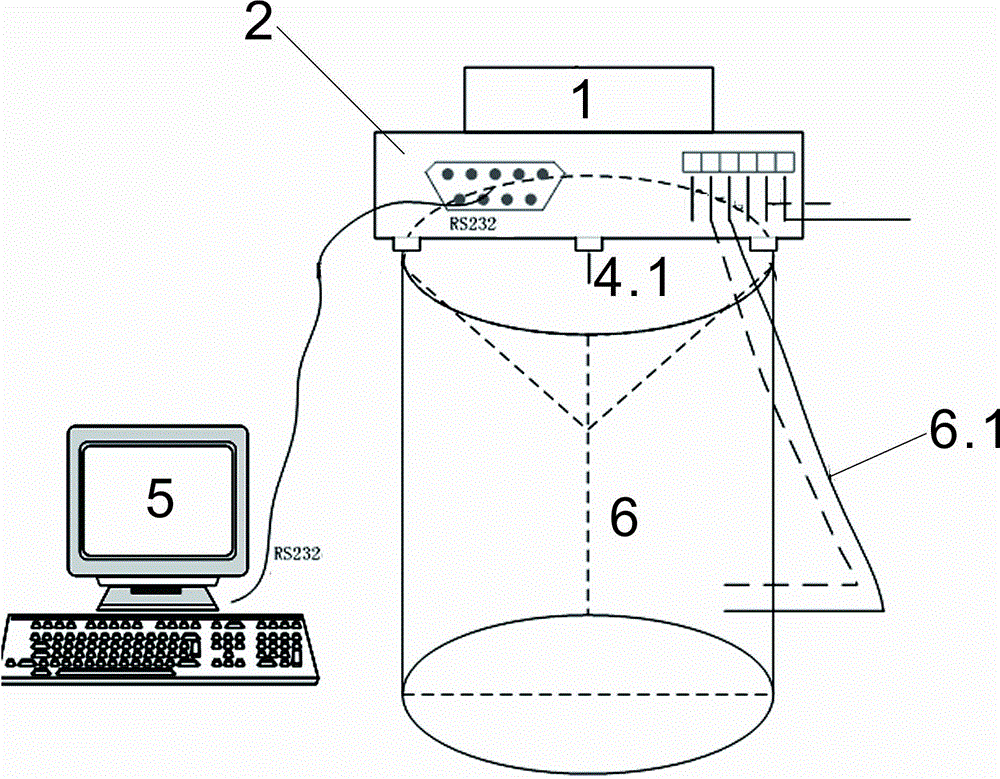

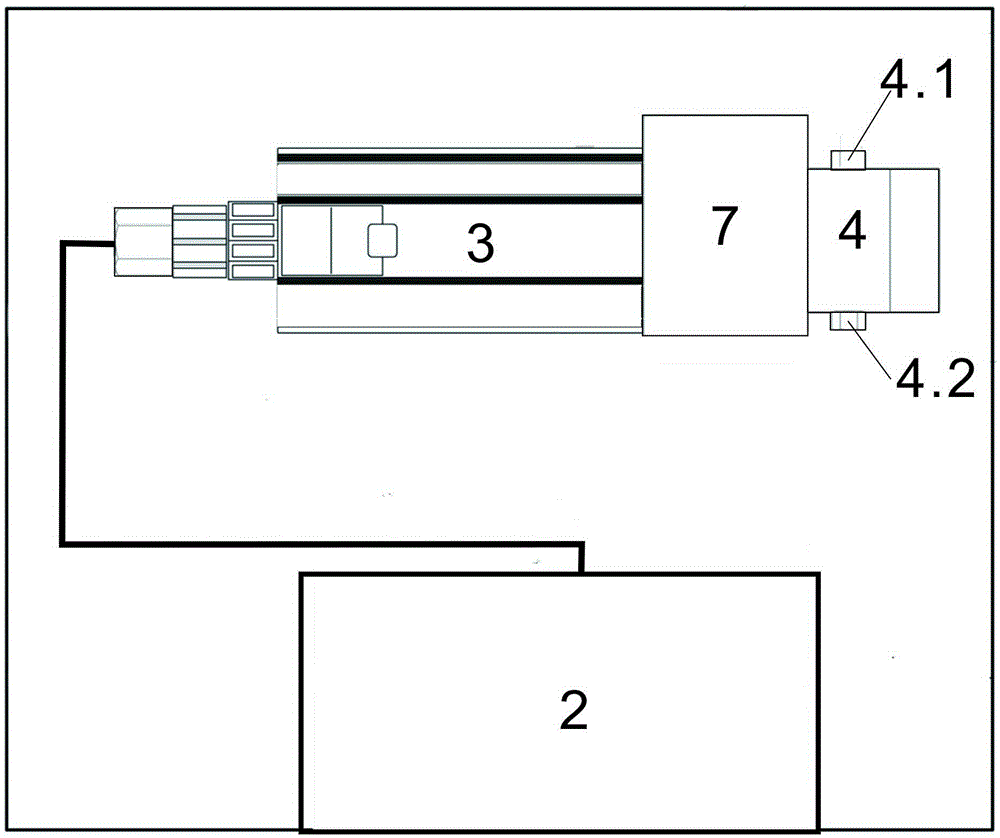

[0021] Such as figure 1 , figure 2 As shown, a portable automatic calibration instrument includes a water storage container 1, a main control circuit board 2, a DC motor 3, a micrometering pump 4, a PC 5, and the PC 5 is connected to the main control circuit board 2, and the main control circuit board 2 is connected to the DC motor 3, and the DC motor 3 is connected to the micro metering pump 4.

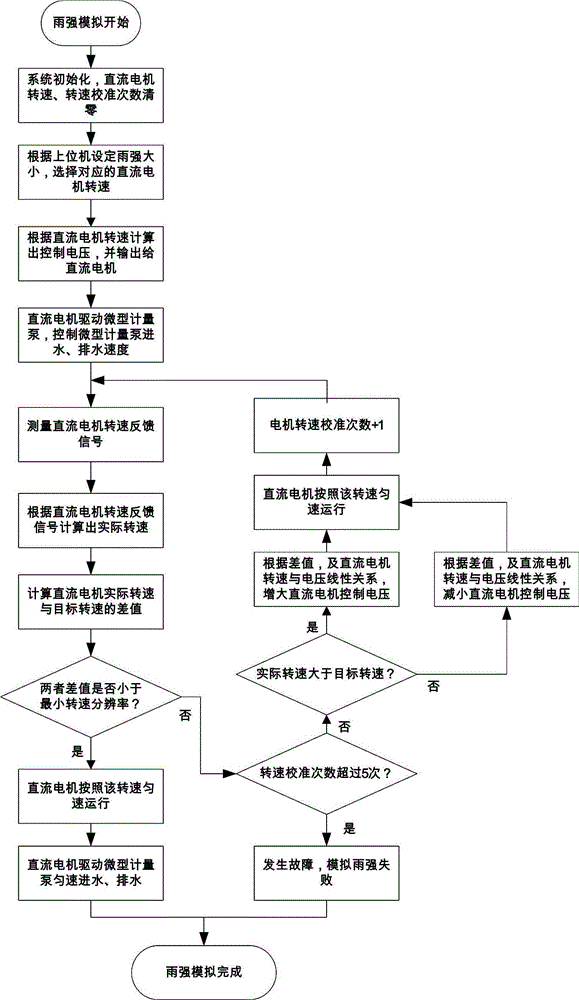

[0022] PC machine 5 comprises operating software, and described operating software can be run in WINDOWS system, comprises a set of calibration program, communicates with main control circuit board 2, can notify main control circuit 2 to initiate calibration task, display calibration Check the calibration process and results, and set working parameters such as simulated rainfall intensity, total rainfall, and rain sensor resolution. The operating software of PC 5 can set the following working parameters: simulated rain intensity, calibration rate to determine total displacement, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com