Preparation technology and quality control method of lotus root and lotus root charcoal control extract

A quality control method and technology of preparation process, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of restricting application and promotion, and achieve the effect of efficient quality control and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] This example proposes the preparation process of the lotus root control extract.

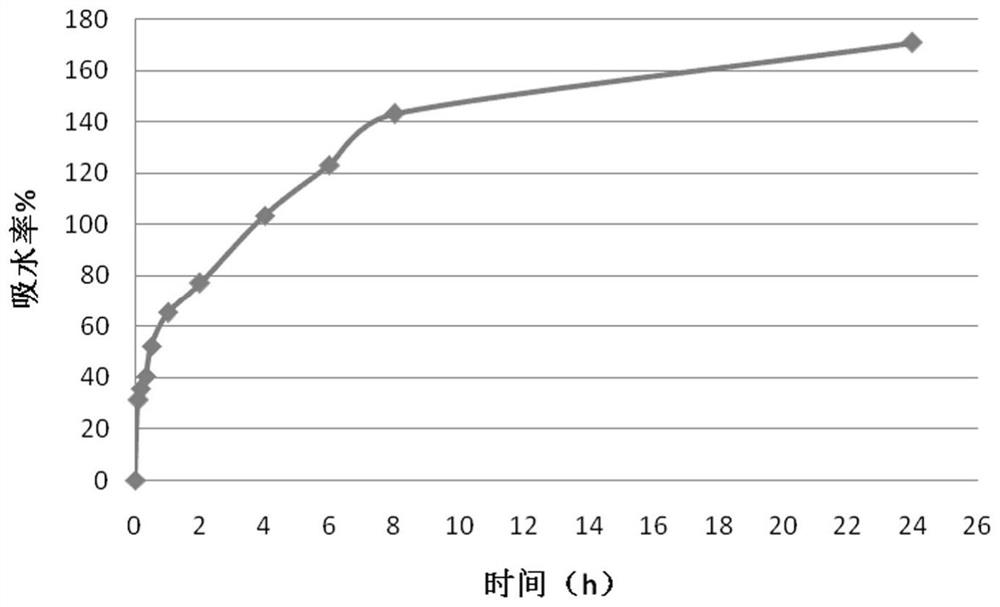

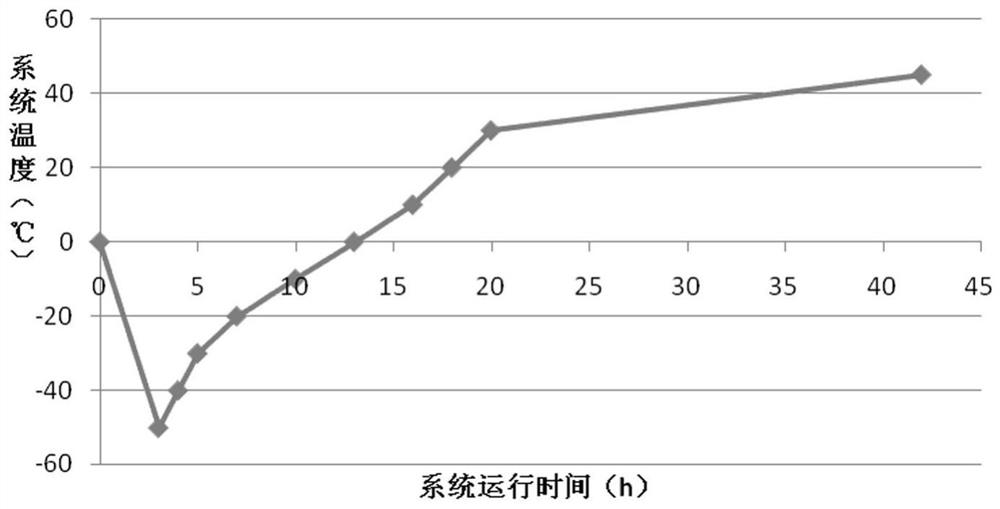

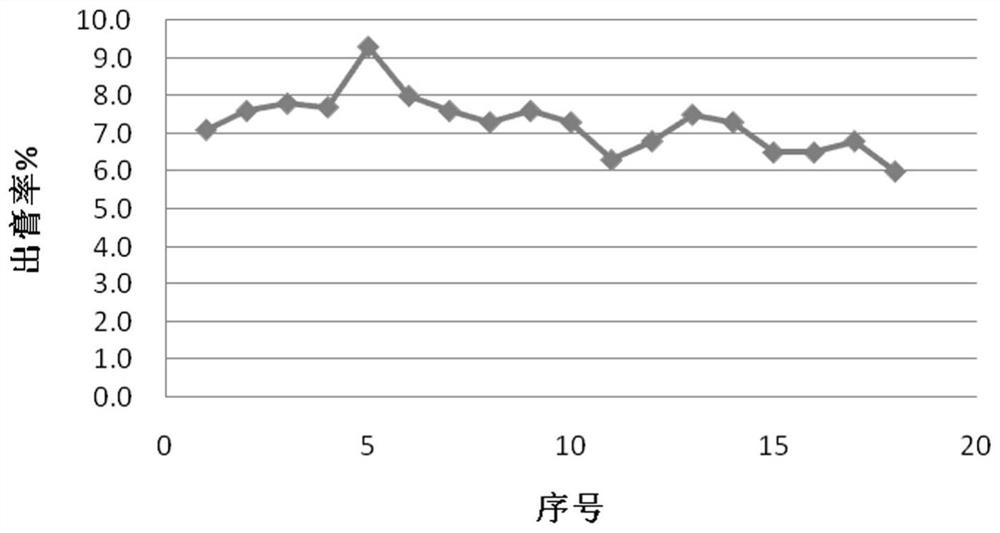

[0097] Take 100g of lotus root decoction slices, add water to decoct twice, add 9 times of water to the first decoction (the height of the decoction slices should be 2-5cm below the liquid surface), soak for 30 minutes, first boil with strong fire, then switch to slow fire for 30 minutes, Use a 200-mesh sieve to filter while it is hot, and the filtrate is quickly cooled to room temperature in a cold water environment; add 7 times the water for the second decoction (the height of the liquid surface should be 2 to 5 cm), first boil it with a strong fire, and then switch to a slow fire. For 20 minutes, use a 200-mesh sieve to filter, combine the water decoction, and quickly cool the filtrate to room temperature in a cold water environment. Under ~60% environment, according to the batch of decoction, quickly collect powder (the range of powder collection rate should be 5.0-10.0%), weigh, pack...

Embodiment 2

[0136] This example relates to the preparation of 18 batches of lotus root control extracts. According to the preparation process described in Example 1, 18 batches of lotus root medicinal materials were taken to prepare the lotus root control extract.

[0137] 1. source

[0138] Collect 18 batches of lotus root medicinal materials from Shuangliu in Sichuan, Shiyan in Hubei, Xixiang in Henan and other production areas, and process them according to the selection method in Example 1. Since the 18 batches of lotus root medicinal materials have been processed at the place of origin to remove impurities, washed, and dried, and almost no impurities exist in the medicinal materials, the medicinal materials of lotus root joints can be regarded as decoction pieces at the place of origin at the same time, and used as raw materials for the preparation of control extracts.

[0139] The above 18 batches of medicinal materials all meet the requirements of the 2015 edition of the Chinese P...

Embodiment 3

[0161] This example is a quality control method for the lotus root control extract. Of course, this quality control method can also be applied to the quality control of the lotus root formula granules or its single Chinese medicine preparation.

[0162] 1. Experimental instruments and materials

[0163] High performance liquid chromatography: Agilent 1260 high performance liquid chromatography, Waters e2695 high performance liquid chromatography, Shimadzu 20AD high performance liquid chromatography;

[0164] Electronic balance: ME204E / 02, MS205DU, XP26 (Mettler-Toledo Instrument Co., Ltd.);

[0165] Ultrapure water machine: cell type 1810A (Shanghai Mole Scientific Instrument Co., Ltd.);

[0166] Ultrasonic cleaner: KQ-600DB type (600W, 40KHz; Kunshan Ultrasonic Instrument Co., Ltd.);

[0167] Chromatographic column: ZORBAX Eclipse XDB-C18 Analytical 4.6×250mm 5-Micron, Diamonsil 5μm C18(2) 250×4.6mm, XBridge C18 5μm 4.6×250mm, Kromasil 100-5-C18 4.6×250mm.

[0168] 2. Reag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com