A kind of method of al-re alloy modified zinc alloy

A zinc alloy and alloy technology, applied in the field of die-casting zinc alloy, can solve the problems of low tensile strength, easy cracking and deformation, poor toughness, etc., and achieve the effect of increasing tensile strength, increasing yield strength and improving microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

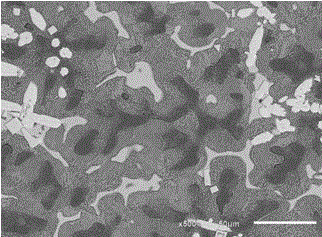

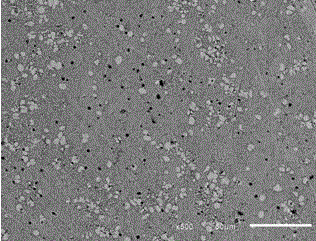

Image

Examples

Embodiment example

[0025] Experimental preparation of 200kg modified die-casting zinc alloy, the steps are as follows:

[0026] 1. Smelting and metamorphic master alloy

[0027] Melting Huoju No. 3-Al-RE master alloy, its composition weight percentage is as follows:

[0028] Torch No. 3 4.8Kg;

[0029] Al-RE1.2Kg.

[0030] (1) Prepare the smelting and Al-RE mixture of Torch No. 3 first, raise the temperature to 620°C, and stir evenly after 60 minutes.

[0031] (2) After heat preservation for 15-25 minutes, cast out of the furnace at a temperature of 600°C.

[0032] 2. Ingredients

[0033] Analyze the components of the configured master alloy and calculate the mass ratio of each component. Then prepare No. 3 and master alloy of the required torch to ensure accuracy, and its composition weight percentage is as follows:

[0034] Torch No. 3 194Kg;

[0035] Huoju No. 3-Al-RE master alloy 6Kg.

[0036] 3. Melting

[0037] Filling and melting: Prepare the master alloy and the torch No. 3 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com