High-performance NdFeB permanent magnet material and preparation method thereof

A permanent magnet material, neodymium iron boron technology, applied in the direction of magnetic materials, inductors/transformers/magnet manufacturing, magnetic objects, etc., can solve the problems of unsatisfactory performance, large usage, low magnetic performance, etc., and achieve the maximum magnetic energy product , low price and cost, and the effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

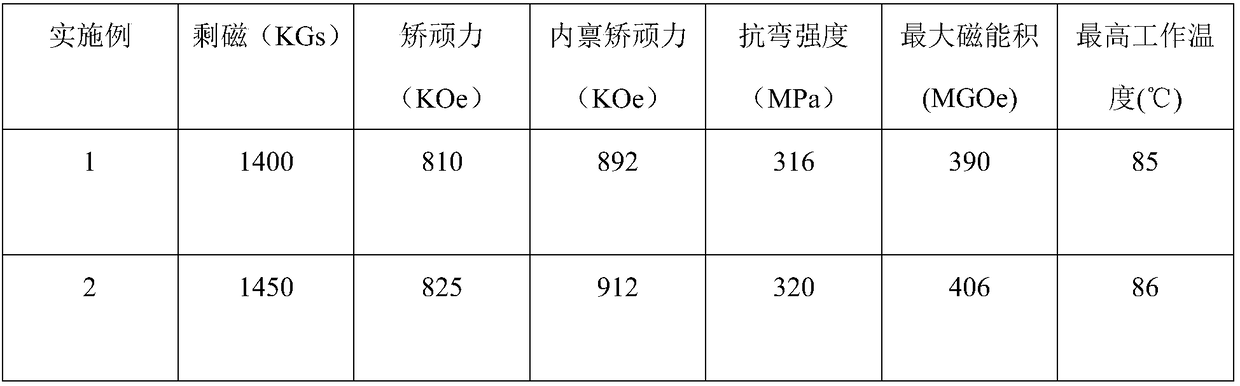

Examples

Embodiment 1

[0023] The permanent magnet material is composed of the following components in weight percentage: PrNd: 32%, Gd1%, Ga 0.1%, Zr0.1%, B 1%, Co0.3%, Al 0.3%, Cu 0.08%, Mo0. 15%, Ti 0.1%, LaCe 0.3%, and the balance is Fe.

[0024] The above-mentioned PrNd in the present invention is a PrNd alloy, wherein the Nd content is 2%.

[0025] The present invention also provides a method for preparing the above-mentioned NdFeB permanent magnet material, the preparation steps are:

[0026] (1) According to the composition and mass percentage of NdFeB magnets, the raw materials are mixed and smelted. After the smelting is complete, it is poured and cooled to form strips;

[0027] (2) carrying out hydrogen crushing and jet milling to the above-mentioned obtained strips to make powder;

[0028] (3) Putting the above-mentioned powder into a forming press mold under the protection of an inert gas and applying a magnetic field to carry out orientation, and press molding after orientation;

[...

Embodiment 2

[0035] The permanent magnet material is composed of the following components in weight percentage: PrNd: 32.5%, Gd 0.70%, Ga0.09%, Zr 0.08%, B 1.0%, Co 0.30%, Al 0.30%, Cu0.08%, Mo0 .20%, Ti 0.20%, LaCe 0.3%, and the balance is Fe.

[0036] Method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com