Control rod driving mechanism and anti-deflection claw assembly thereof

An anti-deflection and hooking claw technology, which is applied in the field of nuclear reactors, can solve the problems of reducing the reliability and service life of the control rod driving mechanism, the control rod driving mechanism cannot keep a fixed vertical state, and the moving armature of the hooking claw assembly is deflected. Reliability and service life, simple and compact construction, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

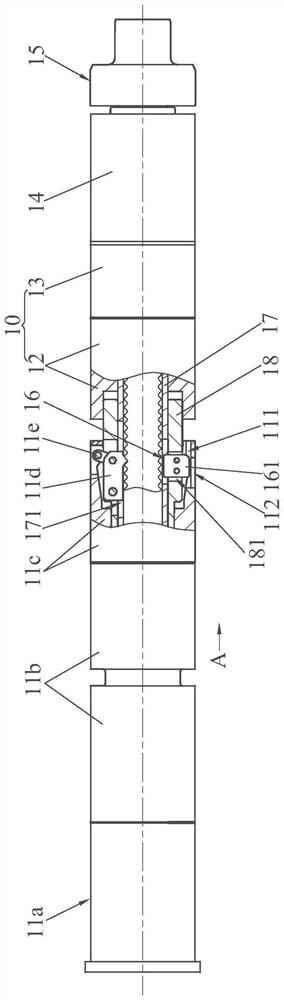

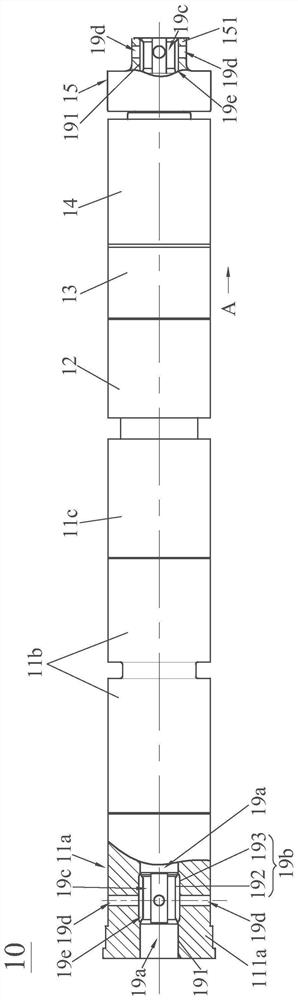

[0039] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

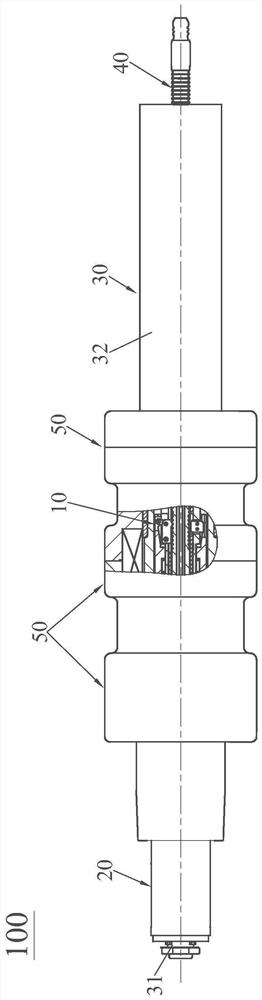

[0040] see figure 1 , The control rod driving mechanism 100 of the present invention includes an anti-deflection hook assembly 10 , a rod position detector assembly 20 , a pressure casing assembly 30 , a driving rod assembly 40 and a coil assembly 50 . The rod position detector assembly 20 is set on the stroke sleeve 31 in the pressure-resistant shell assembly 30, so as to give the actual position signal of the drive rod assembly 40 when the control rod drive mechanism 100 of the present invention is in operation; the drive rod assembly 40 is installed in the sealing shell 32; the coil assembly 50 is set outside the sealing shell 32, and is used to provide power for the action of the anti-deflection hook assembly 10; The gripping, lifting, and inserting functions of the rod assembly 40, while the driving rod assembly 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com