Gluing method of single-sided positive and negative welding battery module

A battery module, positive and negative technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of many types and quantities of production equipment, complex production processes, high production costs, etc., to shorten production time and improve production Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

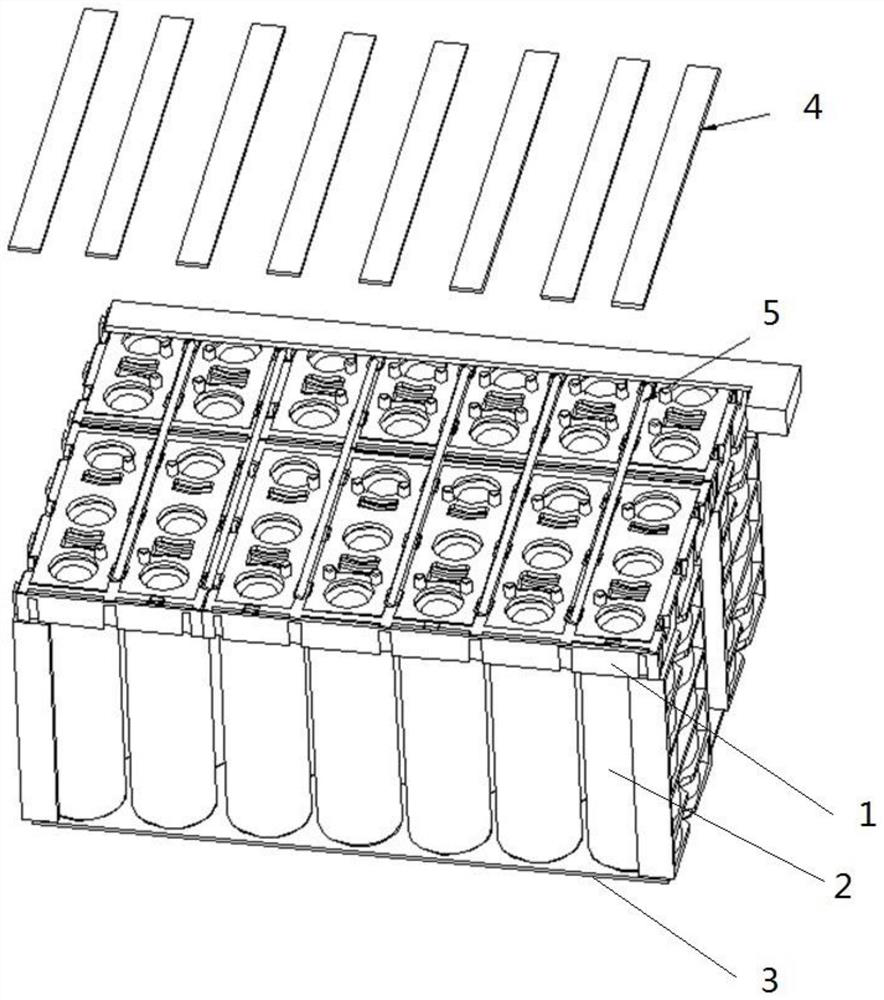

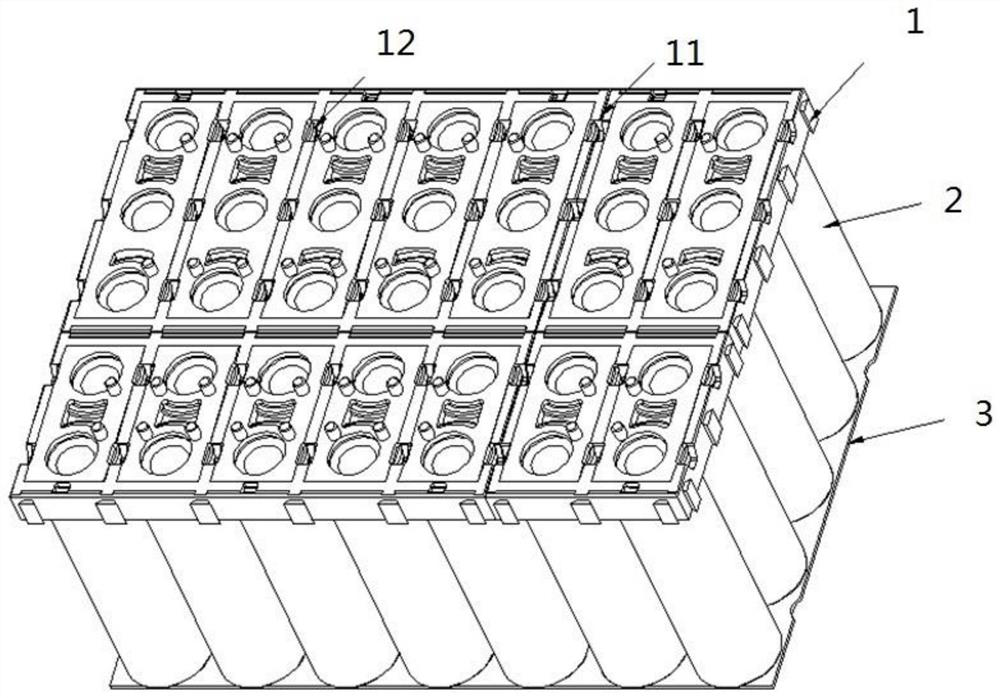

[0024] Such as Figure 1 to Figure 4 As shown, a single-sided positive and negative welding battery module glue method includes the following steps:

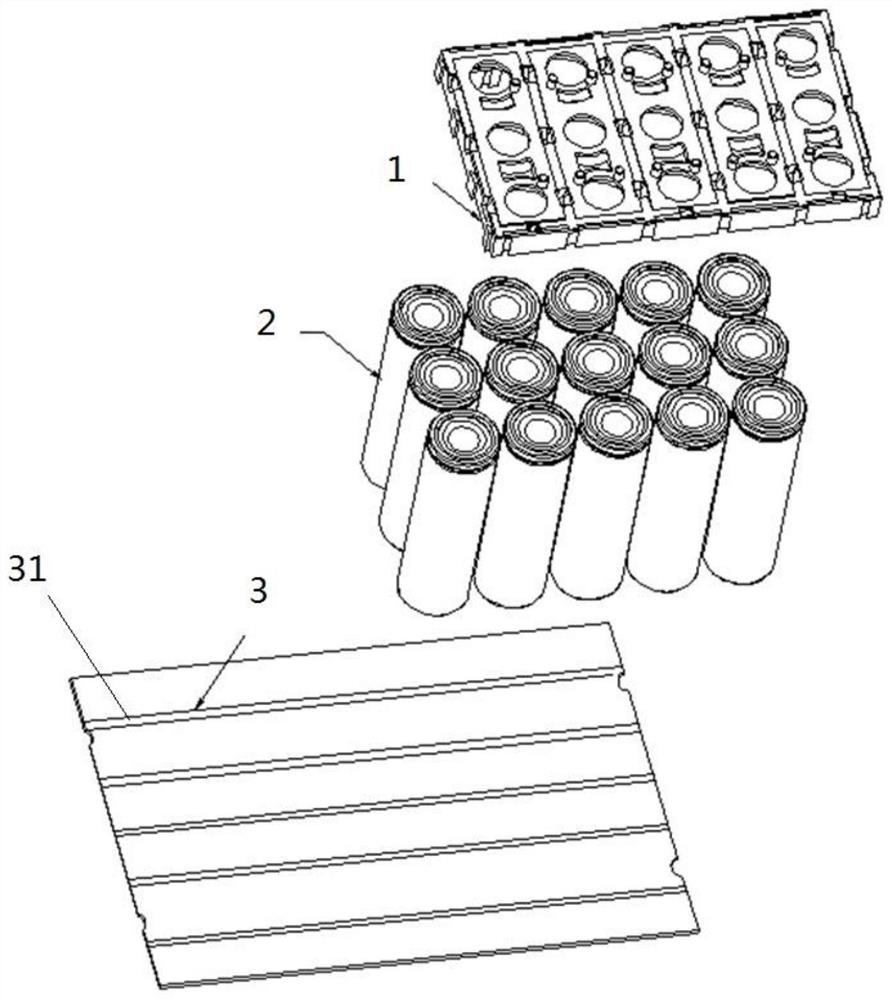

[0025] S1. Insert the battery cell 2 on the lower surface of the battery cell support 1;

[0026] S2, apply glue directly on the glue storage tank 11 on the upper surface of the cell support 1, so that the top of the cell 2 is fixedly bonded to the cell support 1;

[0027] S3, placing the bus bar 4 on the upper surface of the cell support 1 and curing it;

[0028] S4, applying glue on the bottom plate 3;

[0029] S5, fixing the bottom plate 3 to the bottom end of the battery cell 2 and curing and bonding;

[0030] S6. Bind the positive and negative poles of the battery cell 2 to the bus bar 4 through aluminum wires respectively.

[0031] It only needs to apply AB glue on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com