Application method of silicone rubber adhesive in optical variation welding goggles adhesion

An application method and adhesive technology, applied in adhesives, optics, optical filters, etc., can solve the problems of increased application complexity and difficulty, constraints of dimming welding goggles, unstable operation quality, etc., and reduce operating technology and experience requirements, to avoid man-made damage, to reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

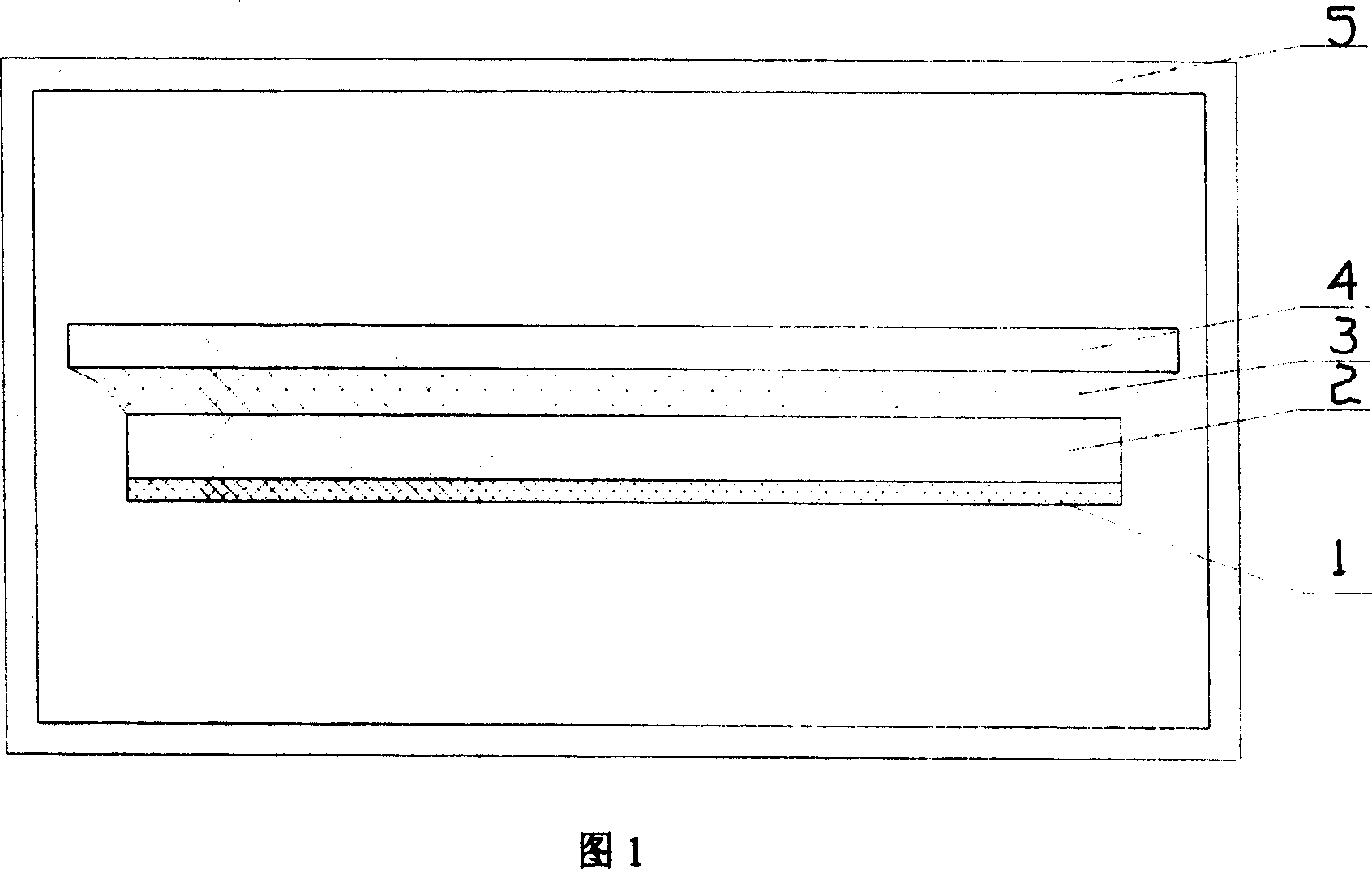

[0009] Because the bonding strength of the silicone rubber adhesive used in this program is not very high and can meet the optical requirements, the present invention adopts the silicone rubber adhesive to replace other traditional adhesives such as optical fir glue, epoxy resin glue, Photosensitive curing glue, etc. The silicone rubber adhesive in the present invention can be commercially available transparent one-component, two-component low-adhesive strength silicone rubber cured at room temperature. Since the bonding strength of these silicone rubber adhesives is not very high, they are just suitable for the bonding between the optical filter element of the present invention and the liquid crystal light valve. In this way, the filter elements and liquid crystal light valves with bonding problems can be disassembled and reworked. The above-mentioned silicone rubber adhesive does not need special treatment, and is cured by reaction at normal temperature and pressure.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com