A manufacturing process of facing small-diameter solid wood finger-joint board or molding

A manufacturing process and technology for finger-jointed boards, which are applied in the field of manufacturing process of small-diameter wood finger-jointed board veneer panels or veneer small-diameter solid wood lines, to achieve the effect of improving environmental protection level, good quality and high grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

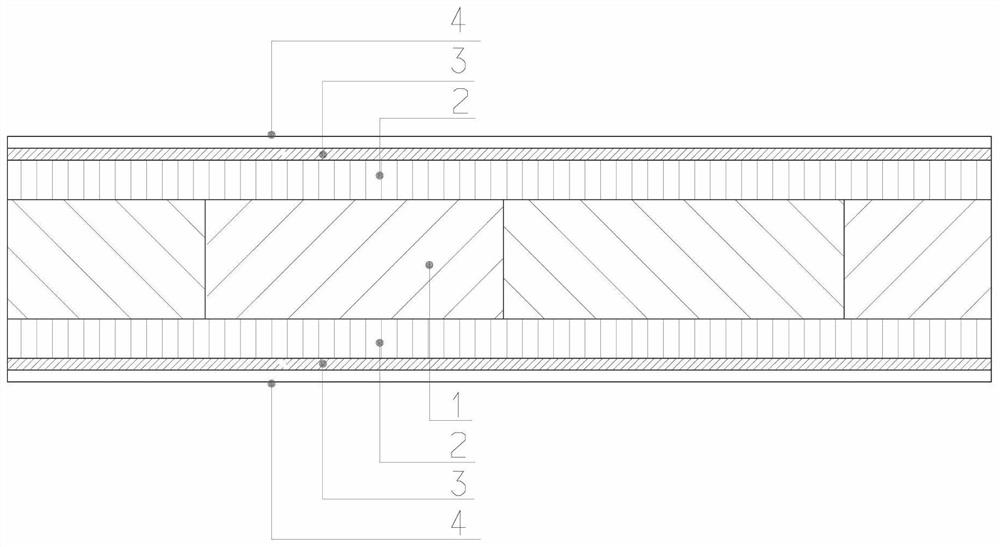

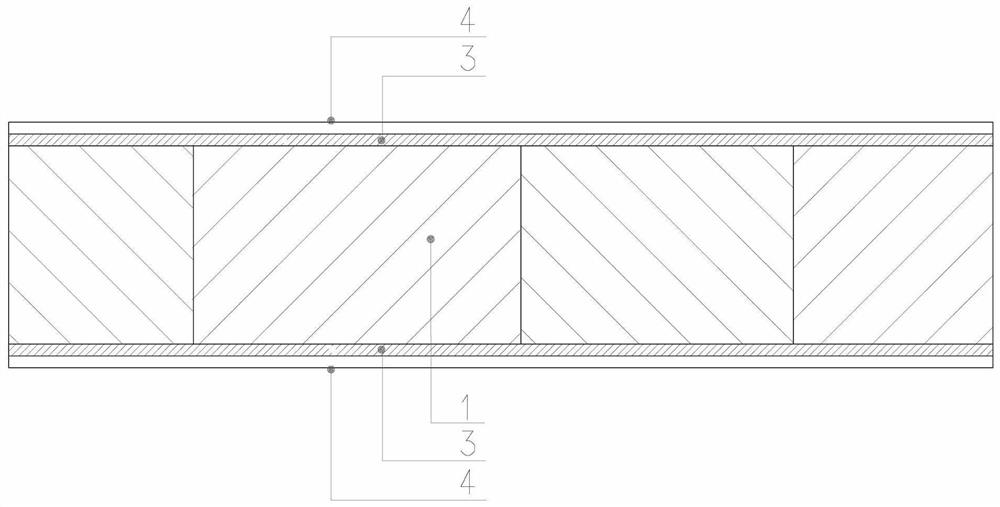

[0056] see Figure 6 ~ Figure 8 , a manufacturing process of facing small-diameter solid wood finger-jointed boards, the key technology of which is to include the following steps:

[0057]1) The specifications purchased from outside the factory are 2450mm long x 1230mm wide x 12-18mm thick or other specifications for the upper and lower board surfaces of small-diameter wooden finger-jointed panels with knots or small-diameter wooden finger-jointed panels without knots The blunt edges, ravines, gaps, and holes of the slats on the board are respectively treated on the surface of the board, such as: scraping putty or roller coating water-based putty to fill up;

[0058] 2) Add a wooden spacer 9.9 between the small-diameter wooden finger-jointed boards after the upper and lower boards have been processed, and stack them into a board stack 9.8;

[0059] 3) Move the plate stack 9.8 into Figure 6 The shown wood absorption water overflows and balances technical system 9 to form a h...

Embodiment 2

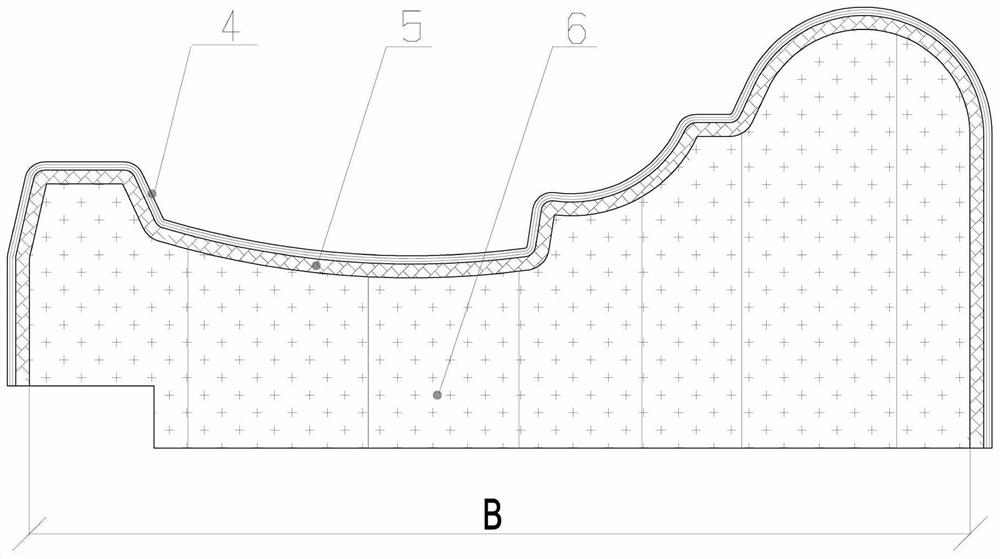

[0067] see Figure 6 , Figure 7 , Figure 9 , a manufacturing process of special-shaped veneer small-diameter solid wood moldings, the key technology of which is to include the following steps:

[0068] 1) Cut the health-preserving board without knots or the health-preserving panel with knots obtained by the method of Example 1 into required specifications and sizes with a panel saw. The health plank slats (flat type);

[0069] 2) Through four-sided milling and other processes, the knotless health-preserving board or the knotted health-preserving board is processed into Figure 9 The special-shaped wooden strip 11 of the health-preserving board shown; and the blunt edges, ravines, and cracks (especially small-diameter wooden finger-jointed boards produced when the technical treatment is carried out in the wood absorption water overflow and balance technology system) that appear locally on the special-shaped surface of the wooden strips. Wood cracks), holes and other natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com