Frequency-tunable microstrip chip resonators loaded with non-contact variable capacitance

A technology of microstrip patch and frequency tuning, which is applied to resonators, circuits, electrical components, etc., and can solve the problem that variable capacitance has a great influence on the radiation performance of resonators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

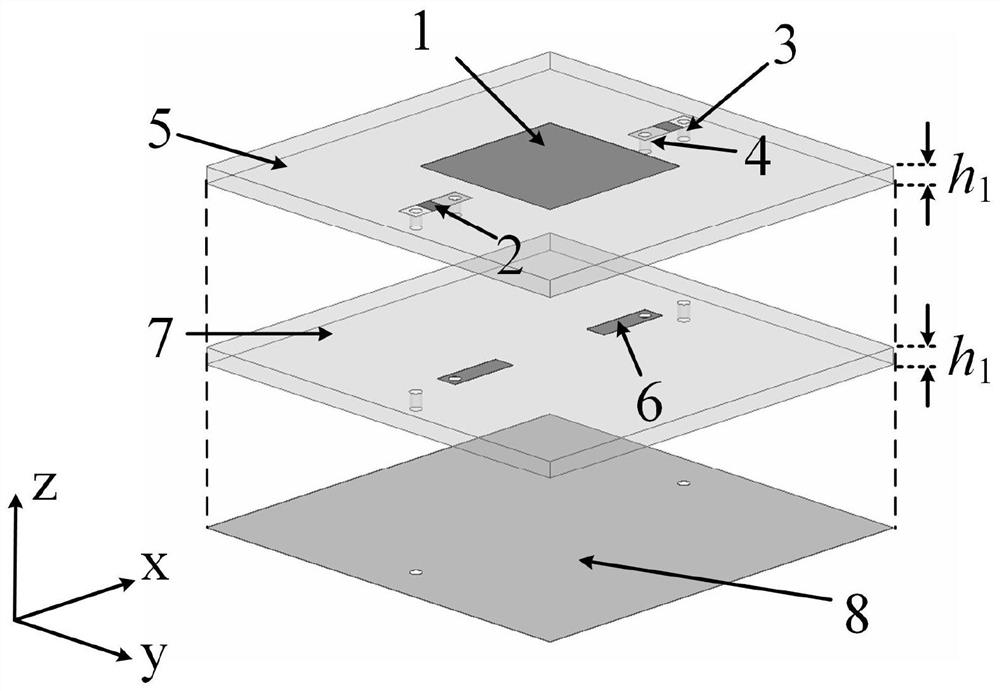

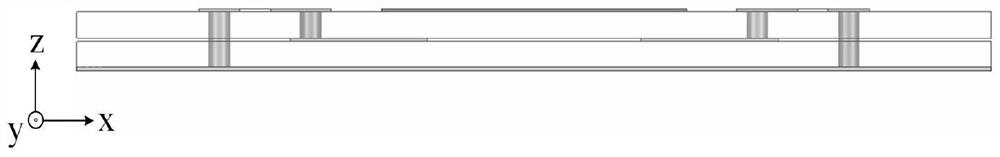

[0016] Such as Figure 1 to Figure 3 As shown, this embodiment is a schematic diagram of a non-contact variable capacitance loaded frequency tunable microstrip resonator implemented in the present invention.

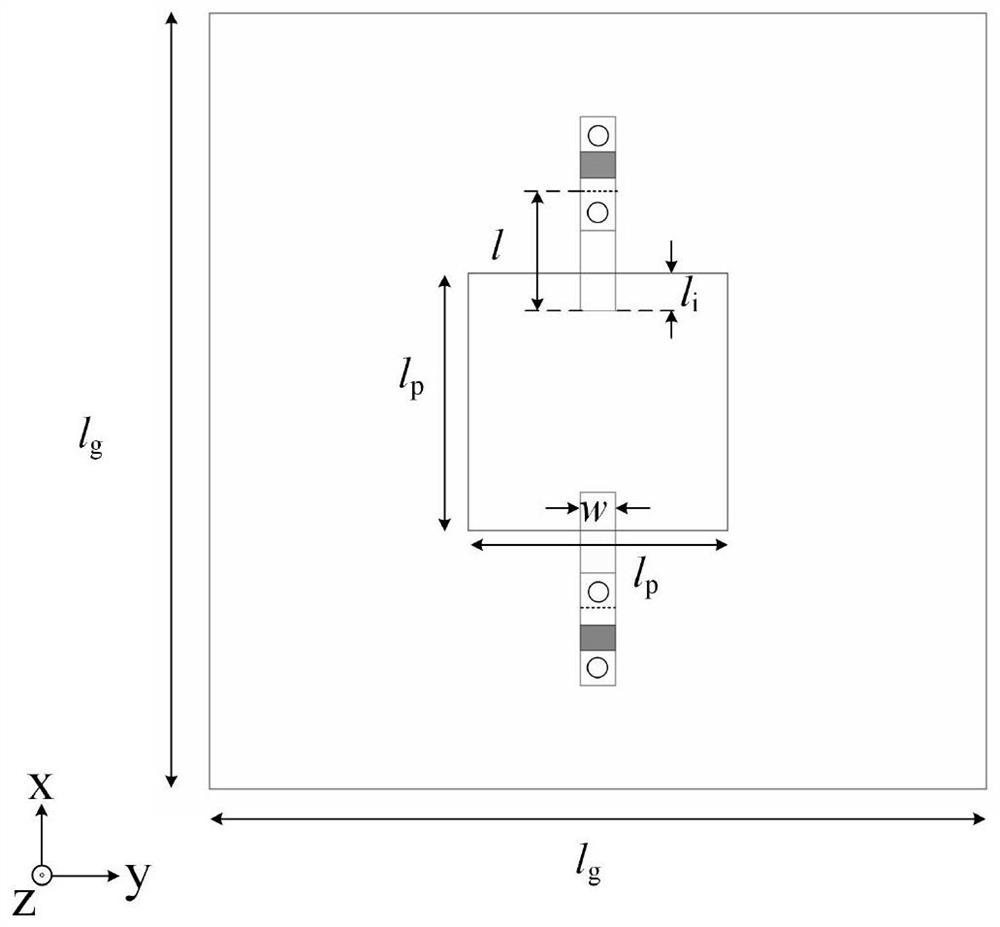

[0017] The microstrip patch resonator implemented in the present invention includes a metal ground 8 , a bottom substrate 7 , a top substrate 5 and a microstrip patch 1 which are sequentially stacked from bottom to top. The microstrip patch 1 is a rectangular microstrip patch, and is disposed in the center of the top substrate 5 . There is a pair of frequency tuning microstrip lines 6 between the top substrate 5 and the bottom substrate 7 , and the frequency tuning microstrip lines 6 are arranged along the centerline of the microstrip patch 1 and arranged symmetrically with respect to the microstrip patch. The microstrip line 6 for freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com