Battery edge folding device and battery processing equipment

A technology of hemming device and battery, applied in metal processing equipment, cylindrical shell battery/battery, feeding device, etc., can solve the problem of low quality of button battery, etc., and achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The battery hemming device provided in the embodiment of the present invention is mainly used in the scene of hemming button batteries (i.e., "soft-packed round lithium button batteries"). The quality of battery production.

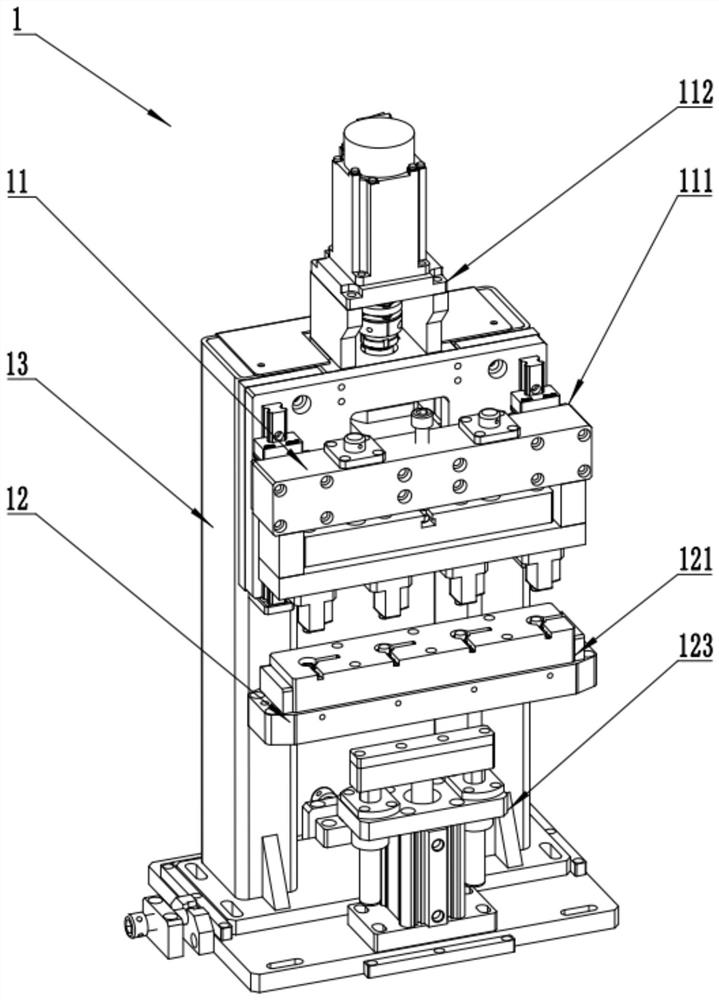

[0061] The battery hemming device provided in this embodiment includes a pre-hemming device 1, a fine hemming device 2, and a finishing hemming worker for transferring the battery from the pre-hemming station of the pre-hemming device 1 to the finishing hemming device 2 Bit flow device.

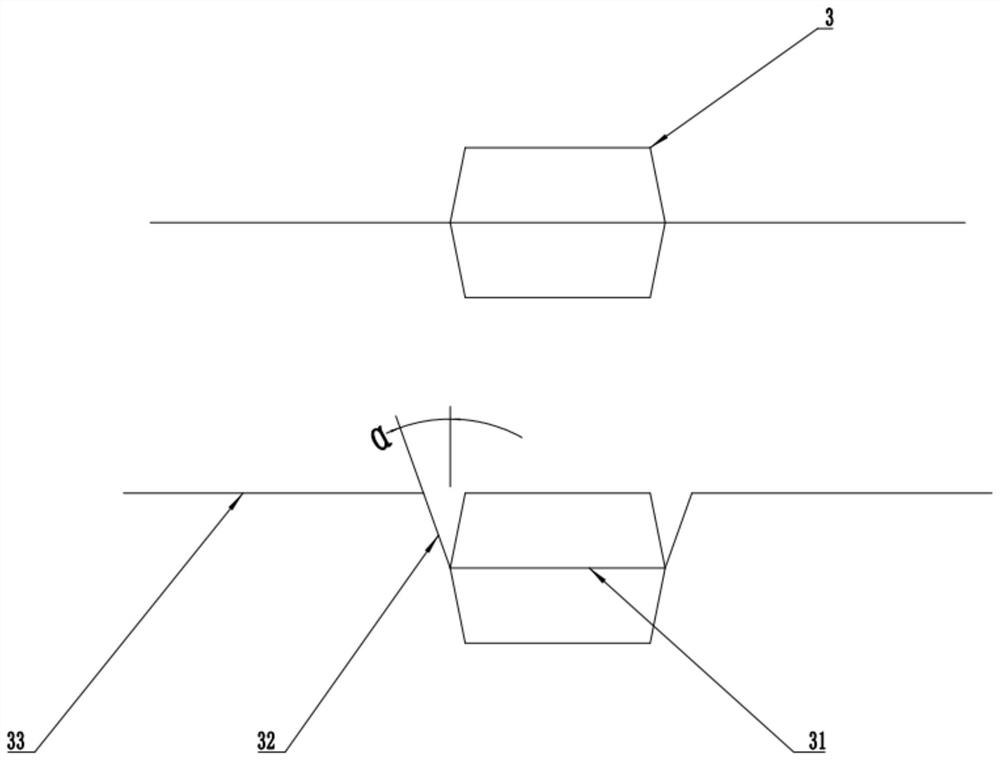

[0062] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the battery 3 includes a battery body 31 and tabs, and the tabs include a fitting section 32 connected to the battery body 31; fold.

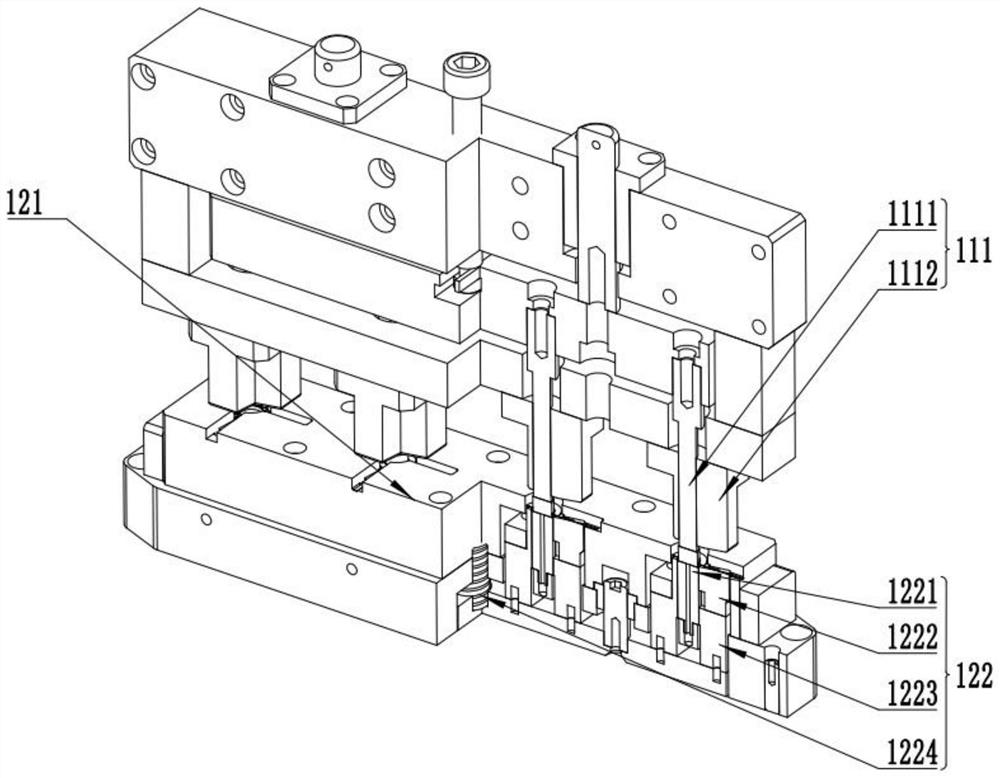

[0063] The fine hemming device 2 includes a hemming mold 21 and a clamping device 22 for clamping the battery body 31 ; the hemming mold 21 is provided with a through hole 211 .

[0064] The clamping device 22 is also used to drive the battery body 31 to...

Embodiment 2

[0096] The battery processing equipment provided in this embodiment includes downstream equipment and the battery folding device as in Embodiment 1; the circulation device of the battery folding device is used to transport the folded battery to the downstream equipment. Embodiment 1 describes the specific structure and technical effects of the battery hemming device, and this embodiment 1 cites the battery hemming device, which also has its technical effects.

[0097] To sum up, the battery processing equipment provided in this embodiment performs secondary folding on the tabs of the battery, so that the tabs of the battery after the folding process are more closely attached to the round body of the button battery, thereby improving the production capacity of the button battery. Quality, and has the characteristics of high efficiency, high precision, high safety factor and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com