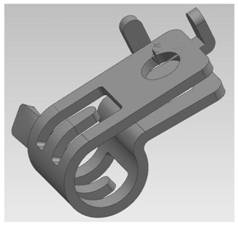

Progressive die design of hoop parts

A mold design and mold technology, which is applied in the stamping and forming field of parts, can solve the problems of many processing steps, difficult mold adjustment, small blanking gap, etc., and achieve the effects of simplified workload, extensive large-scale production, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

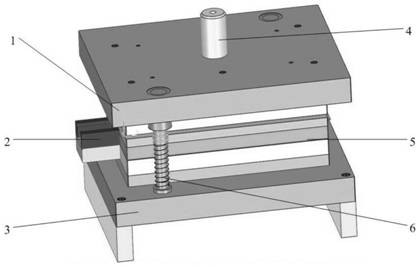

[0029] The inventive device such as figure 1 As shown, it includes a multi-station progressive die upper die 1, a stripper plate 2, a lower die 3, a guide pin 4, an insert 5 and a limit screw 6.

[0030] The device of the present invention assembles each part of the mold into a mold frame by means of assembly. The assembly of upper mold 1 and lower mold 3 fixed plate and stripper plate 2 plays a very important role in the assembly of multi-station progressive dies. The assembly accuracy of these three plates and the manufacturing accuracy of insert 5 determine the multi-position of the whole set. The quality of station progressive die. When assembling, select the datum surface and the datum hole as the datum, and the assembly datum coincides with the machining datum. The insert 5 should have an interference during assembly, and fasten it with pins or fastening screws after the embedding is completed.

[0031] Select the plane where the fixed plate of the die 3 is located as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com