Product press-fit device suitable for oil press

A technology of hydraulic presses and products, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems affecting product performance, insufficient press fit, excessive press fit, etc., to improve production pass rate, facilitate disassembly and assembly, Impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

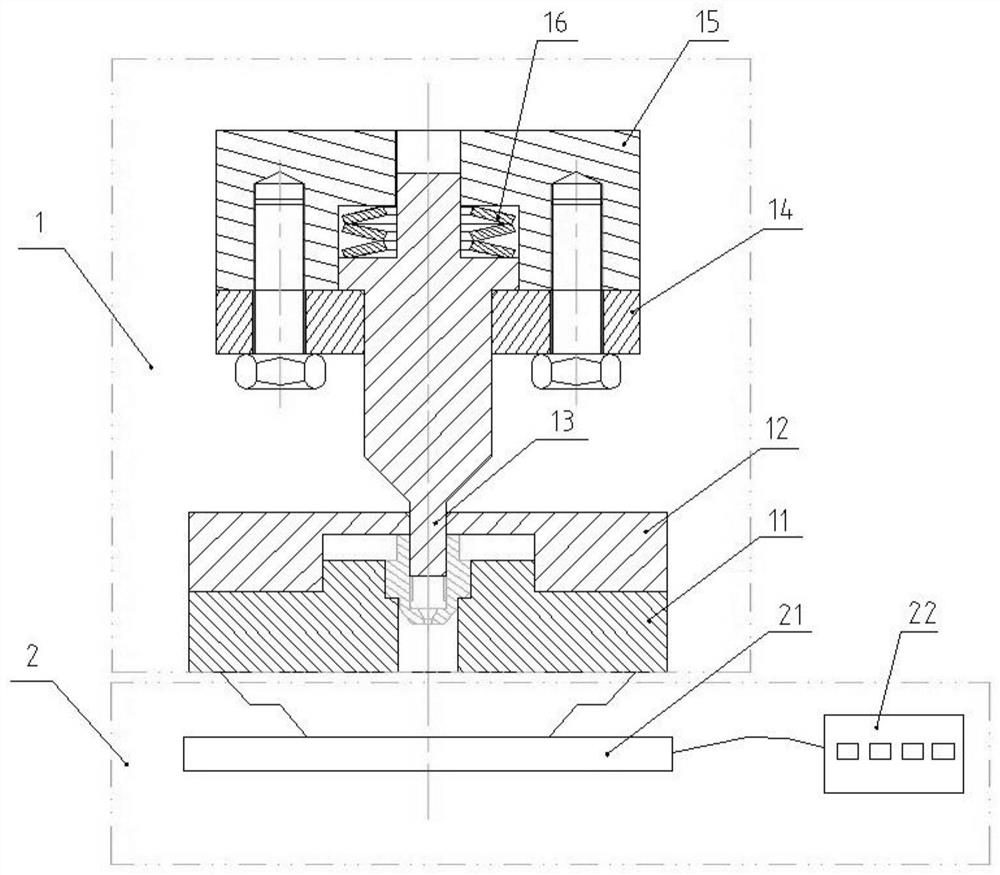

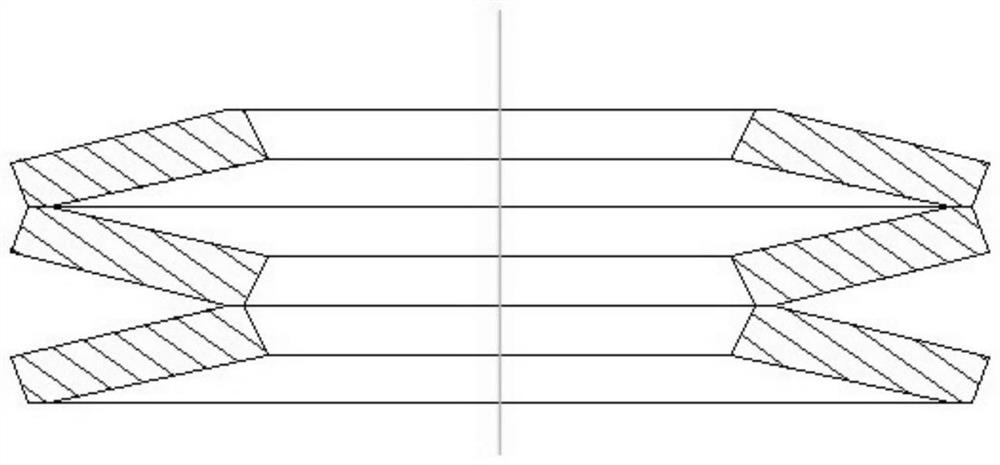

[0018] Such as Figure 1 to Figure 2 As shown, the present invention provides a product press-fitting device suitable for hydraulic presses, including: a pressurization module 1 and a display module 2; One 14, guide block two 15 and combined disc spring 16; the display module 2 is provided with a plane pressure sensor 21 and a digital display 22.

[0019] During the press-fitting process of the product, pressure is applied to the guide block 2 15, and the guide block 15 moves downward along the outer wall of the pressure block 13, and transmits the pressure to the combined disc spring 16; the pressure after the elastic deformation of the combined disc spring 16 is buffered The block is transmitted to the pressurized product, and acts on the plane pressure sensor 21 under the product, which is displayed on the digital display 22 and controlled by the upper limit alarm to realize the press fit and protection of the product.

[0020] The limit block 12 is located directly above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com