Temperature control and preheating intelligent control device for corrugated boards

A technology of intelligent control and corrugated cardboard, which is applied in the field of corrugated paper processing, can solve the problems of manpower consumption and low work efficiency, and achieve the effects of saving investment, improving work efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

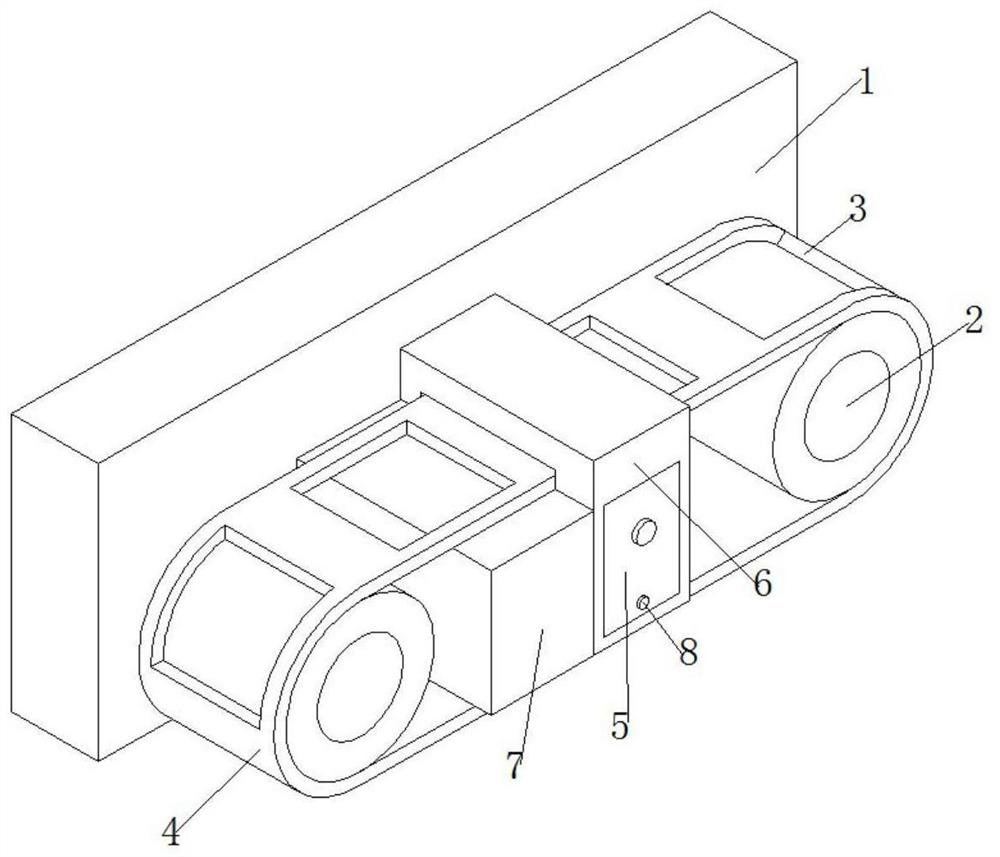

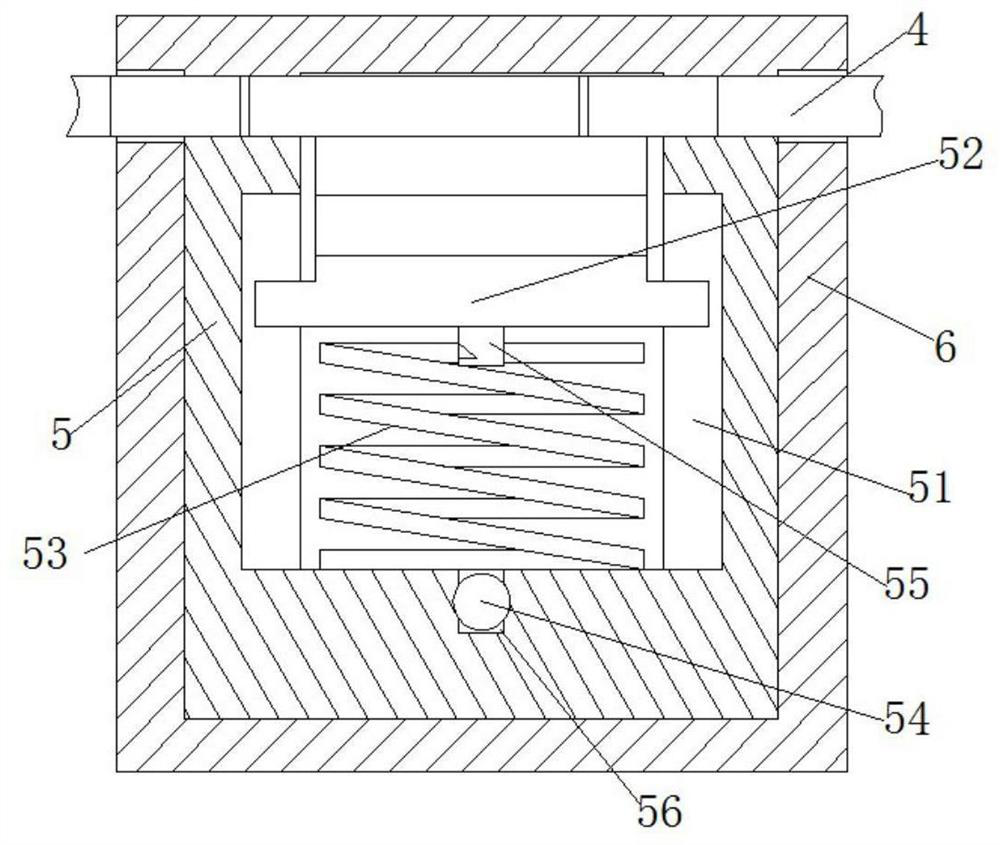

[0021] see Figure 1-3 , this embodiment provides an intelligent control device for temperature control and preheating of corrugated cardboard, including a mounting board 1, a temperature control board 7 is fixedly installed on one side of the The control board 7 heats up, and the side of the installation board 1 where the temperature control board 7 is installed is rotated and the transmission shaft 2 is installed, and the transmission shaft 2 is driven to rotate by the servo motor.

[0022] The radial outer wall of the transmission shaft 2 is attached with a transmission plate 4, and the transmission plate 4 is driven by the friction force between the transmission plate 4 and the transmission shaft 2 through the rotation of the transmission shaft 2. A packing chamber 6 is arranged between the two transmission shafts 2. One side of the stuffing chamber 6 is fixedly connected with the mounting plate 1, the transfer plate 4 runs through the top side wall of the stuffing chamber...

Embodiment 2

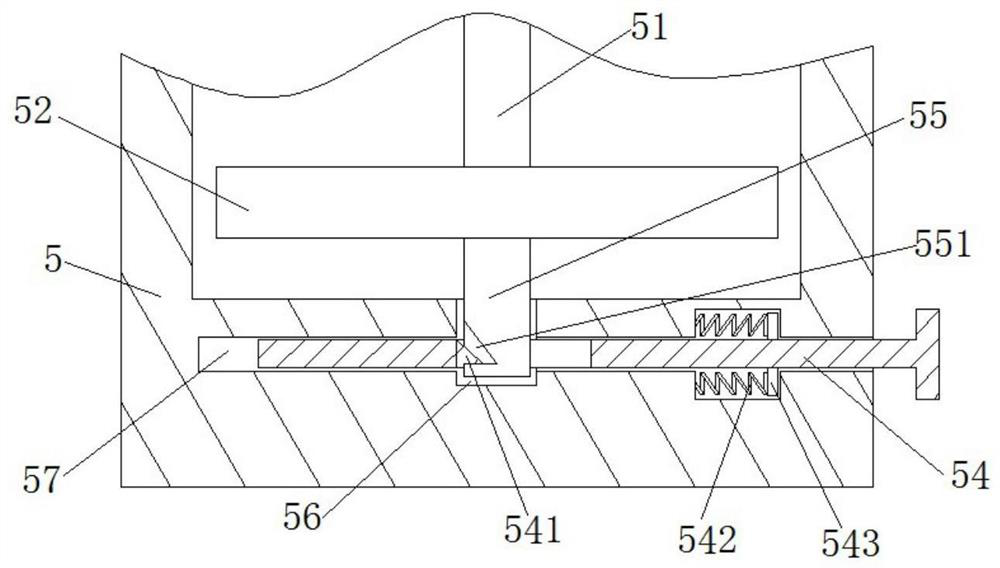

[0027] see Figure 2-3 On the basis of Embodiment 1, a further improvement has been made: the bottom surface of the inner cavity of the storage chamber 5 is provided with a fixed groove 56, and the side of the top plate 52 close to the bottom surface of the storage chamber 5 is fixedly connected with a fixed rod 55, and the tip of the fixed rod 55 is provided with a The wedge-shaped groove 551 fixed rod 55 is matched with the fixed groove 56, and the inner cavity of the bottom surface of the material storage chamber 5 is provided with a mounting groove 57 vertically connected with the fixed groove 56. Through the side wall of the limit rod 54, the side of the limit rod 54 close to the fixed rod 55 is provided with a wedge-shaped block 541 that matches the wedge-shaped groove 551. 52, insert the fixing rod 55 into the inside of the fixing groove 56.

[0028] Wherein, the limit rod 54 side wall is fixedly connected with a horizontal plate 543, and the horizontal plate 543 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com