Hoisting method of FPSO living quarter module

A hoisting method and living area technology, applied in the direction of transportation and packaging, load hanging components, cranes, etc., can solve the problems of increasing the production cost and waste of hanging beams, and achieve the effect of reducing dock cycle, reducing material waste, and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

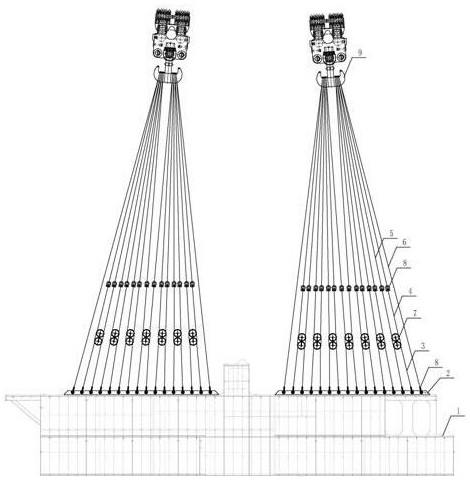

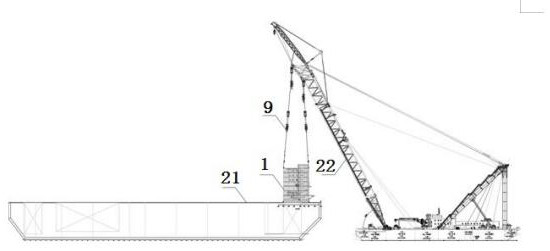

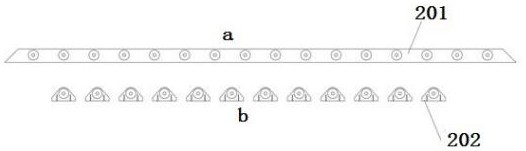

[0019] Examples, combined with Figure 1-3 , a hoisting method for an FPSO living quarters module, comprising a living quarters module 1, a floating crane 22 and a hook 9, the hook 9 being arranged on the floating crane 22, and an eye plate 2 and The triangular plate strengthening structure includes the following steps:

[0020] Step 1: The living area module 1 is carried on the slideway, and hoisted onto the ship using a floating crane. During hoisting, the connection between the eye plate 2 and the hook 9 on the top of the living area module 1 is carried out through four sets of wire ropes, double pulley blocks 7 and shackles 8. connect;

[0021] Step 2, the four groups of wire ropes in step 1 are respectively hook wire rope 5, eye plate wire rope 3, steering wire rope 4 and joint wire rope 6, and the four groups of wire ropes are respectively connected between eye plate 2 and suspension hook 9;

[0022] Step 3, the hook wire rope 5 is directly hung on the hook 9, the pipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com