Automatic drainage system and method for compressed air pipeline

A technology of compressed air pipes and automatic drainage, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of untimely drainage, troublesome operation, and increased workload of staff, so as to reduce labor intensity, Convenient control and timely operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

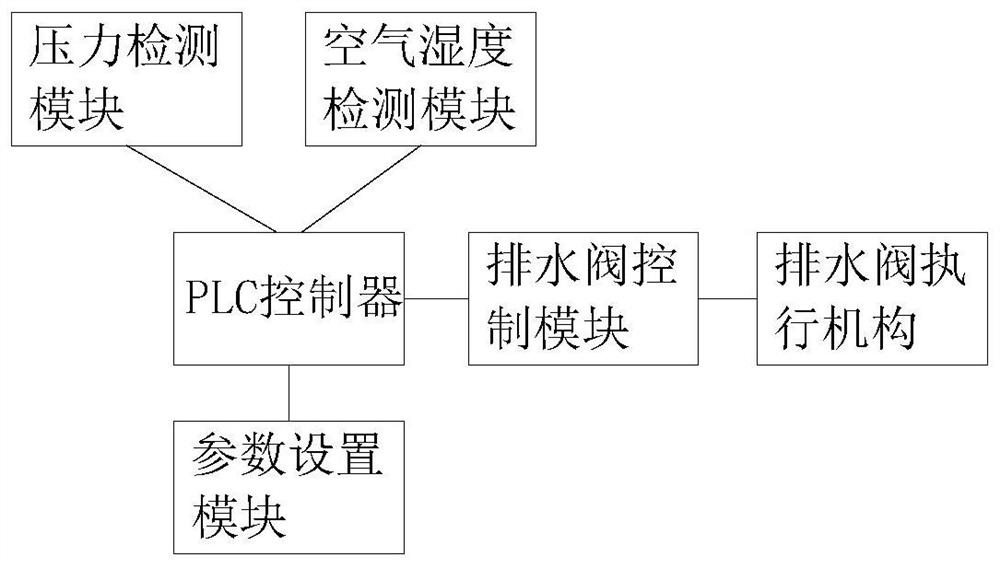

[0023] Such as figure 1 As shown, the compressed air pipeline automatic drainage system of this embodiment includes a PLC controller, the PLC controller is electrically connected to a drainage control module, and the drainage control module is electrically connected to a drainage valve installed at the outlet of the buffer tank of the compressed air pipeline, The PLC controller is electrically connected with a pressure detection module, an air humidity detection module and a parameter setting module respectively, and the parameter setting module is used to set the drainage time of the drainage valve, the drainage pressure of the drainage valve, and the drainage waiting time.

[0024] The pressure detection module can detect the pressure of the compressed air, and the air humidity detection module can detect the humidity of the compressed air. The parameter setting module can set parameters such as the drainage time of the drainage valve, the drainage pressure of the drainage v...

Embodiment 2

[0028] A method for automatic drainage of compressed air pipelines, comprising the steps of:

[0029] S1: According to the parameters including air humidity and compressed air pressure, set the drain valve drain time, drain valve drain pressure, and drain waiting time in the DCS system;

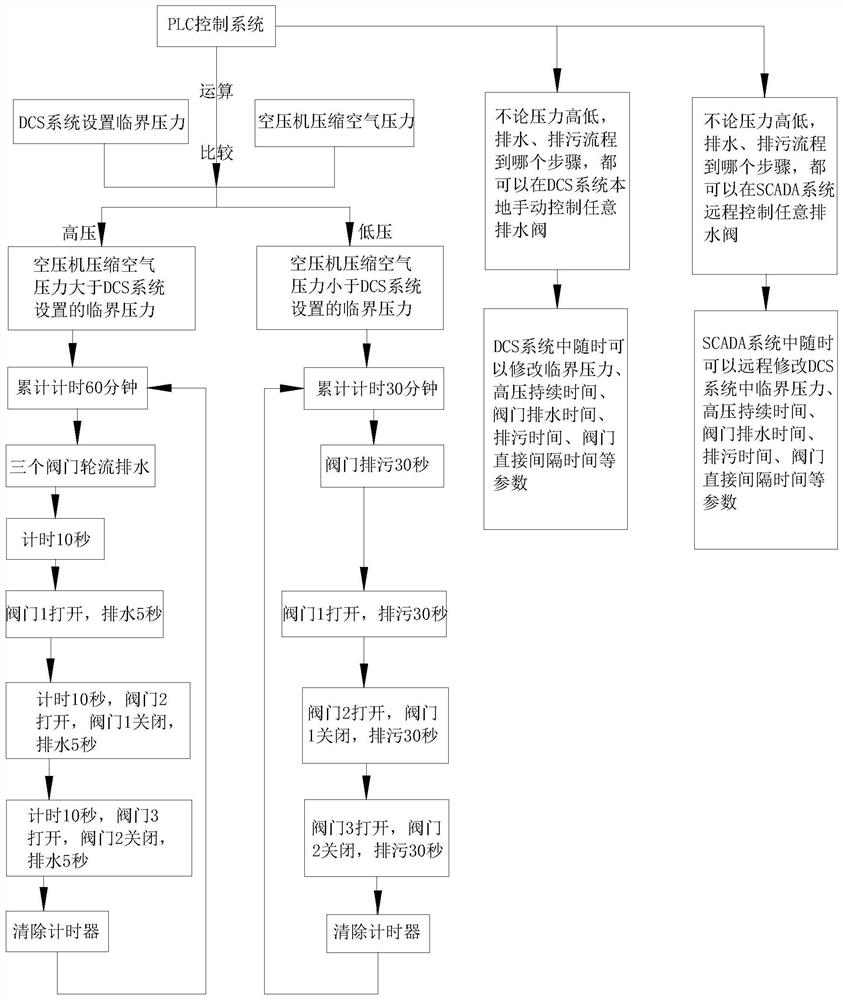

[0030] Among them, such as figure 2 As shown, when setting the drainage time of the drainage valve, the drainage pressure of the drainage valve, and the waiting time of the drainage valve in the DCS system, when the compressed air pressure is lower than the critical pressure of the drainage valve, the drainage valve is in the sewage discharge state. When the setting exceeds 30 minutes in total, 3 The valves take turns to discharge sewage for 30 seconds, and then restart the counting work; when the pressure is higher than the critical pressure of the drain valve, the drain valve is in the draining state. After setting the cumulative pressure to maintain the state for 1 hour, the three valves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com