Line contact friction testing machine with pressure scanning function, and pressure detection method

A friction testing machine, line contact technology, applied in the direction of measuring fluid pressure, measuring device, adopting mechanical device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

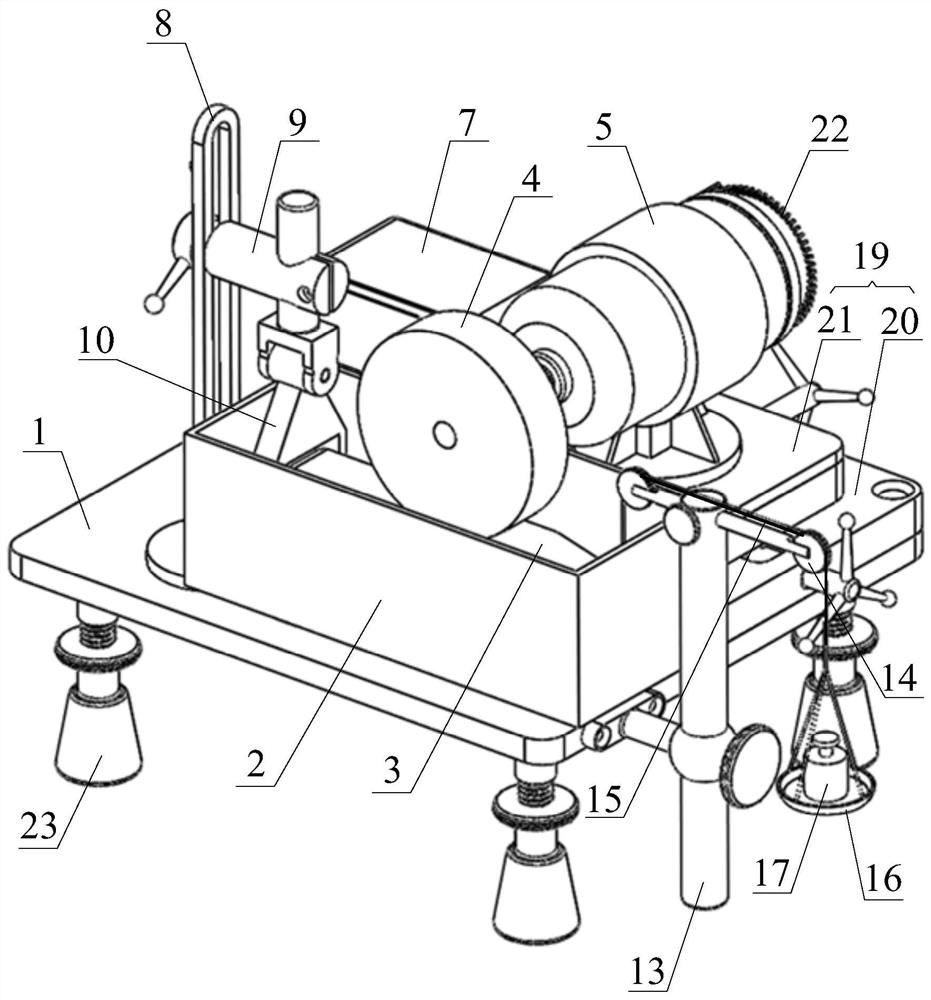

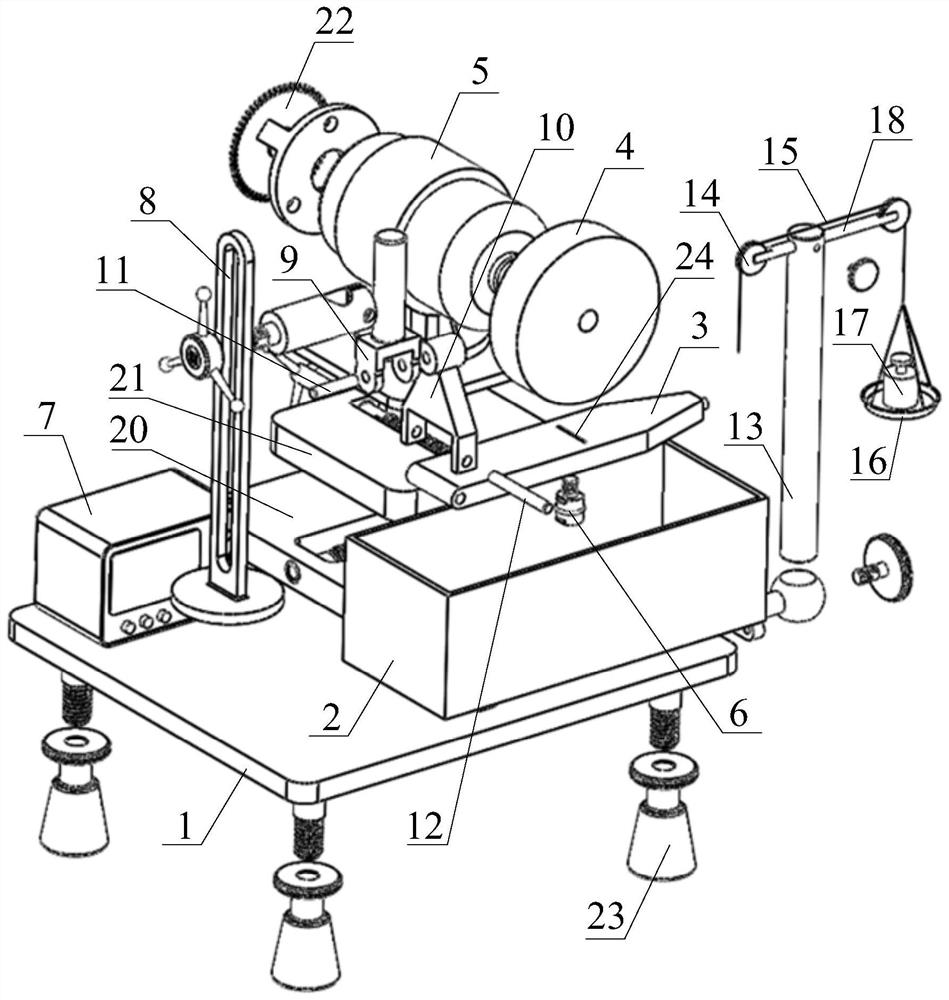

[0053] This embodiment provides a line contact friction testing machine with pressure scanning function, such as figure 1 and figure 2 As shown in the structure, the line contact friction testing machine includes a base 1, a lubricating oil tank 2, a friction plate 3, a friction disc 4, a driving motor 5, a hanger, a loading mechanism and a pressure sensor 6;

[0054] A lubricating oil tank 2 is installed on the top of the base 1; the base 1 is used as the installation basis of the line contact friction testing machine; in order to facilitate the adjustment of the base 1, multiple height-adjustable support feet can also be installed on the top of the base 1 23, at figure 1 and figure 2 The four corners of the bottom of the base are respectively provided with a supporting foot 23, and the height adjustment of the supporting foot 23 can be realized by threads;

[0055] Lubricating oil groove 2 is a groove structure with an open top, and lubricating oil and friction plate 3 ...

Embodiment 2

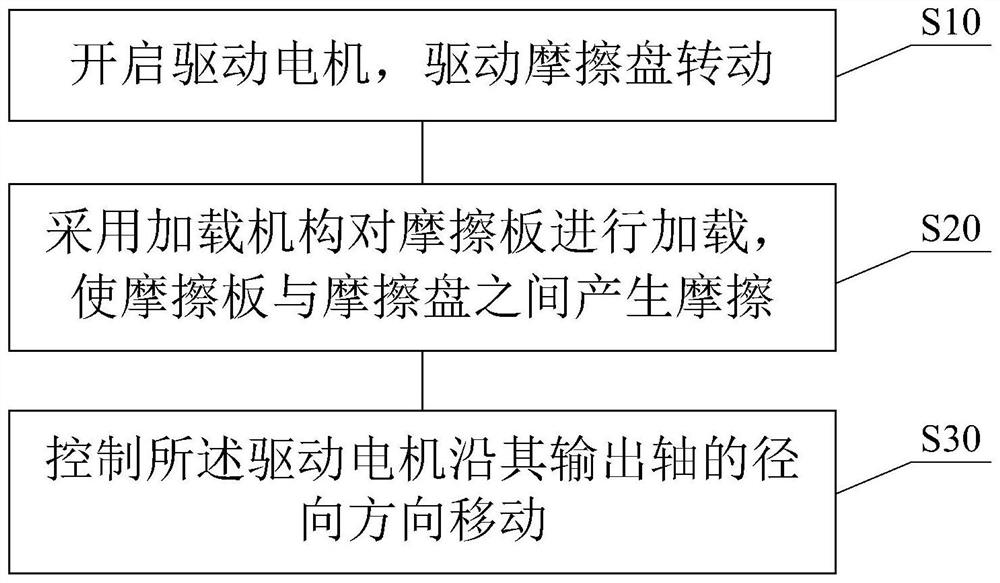

[0071] This embodiment provides a method for detecting the pressure distribution in the lubricating oil film. When detecting the internal pressure of the lubricating oil film, the line contact friction testing machine provided by the above embodiment is used. Refer to image 3 , the detection method includes the following steps:

[0072] Step S10, turn on the drive motor 5 to drive the friction disc 4 to rotate;

[0073] Step S20, using a loading mechanism to load the friction plate 3 to cause friction between the friction plate 3 and the friction disc 4;

[0074] Step S30, controlling the drive motor 5 to move along the radial direction of its output shaft.

[0075] The line contact friction between the friction disc 4 and the friction plate 3 can be realized by using the above-mentioned line contact friction testing machine, and the friction disc 4 is controlled to reciprocate relative to the friction plate 3 while friction occurs between the friction disc 4 and the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com