Logistics material prediction method based on gray model

A technology of gray model and prediction method, which is applied in the field of logistics material prediction based on gray model, can solve problems such as insufficient consideration of important parameters, lack of internal mechanism research of prediction objects, and high difficulty of mechanism models, so as to simplify calculation difficulty, The effect of small amount of calculation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

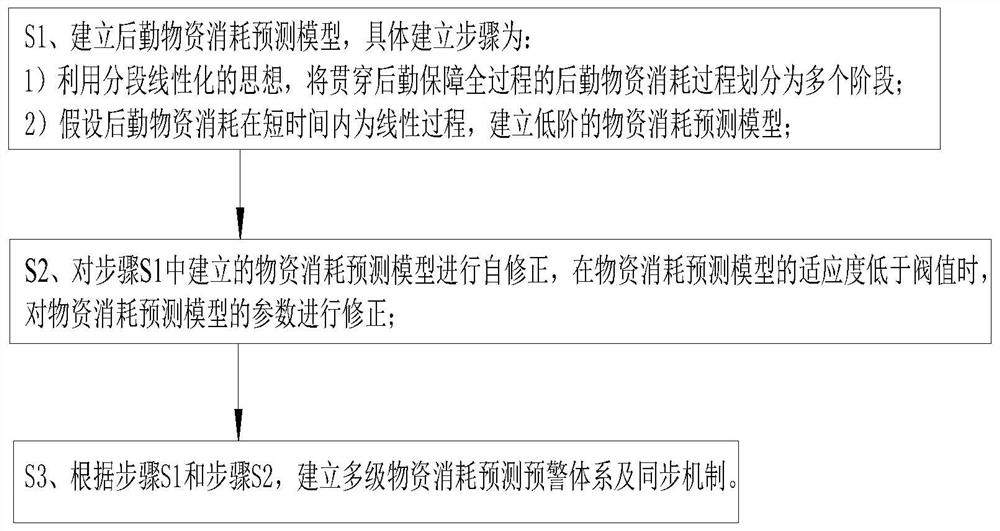

[0051] Embodiment: a kind of logistic material prediction method based on gray model, such as figure 1 As shown, it specifically includes the following steps:

[0052] S1. Establish a logistics material consumption prediction model. The specific establishment steps are:

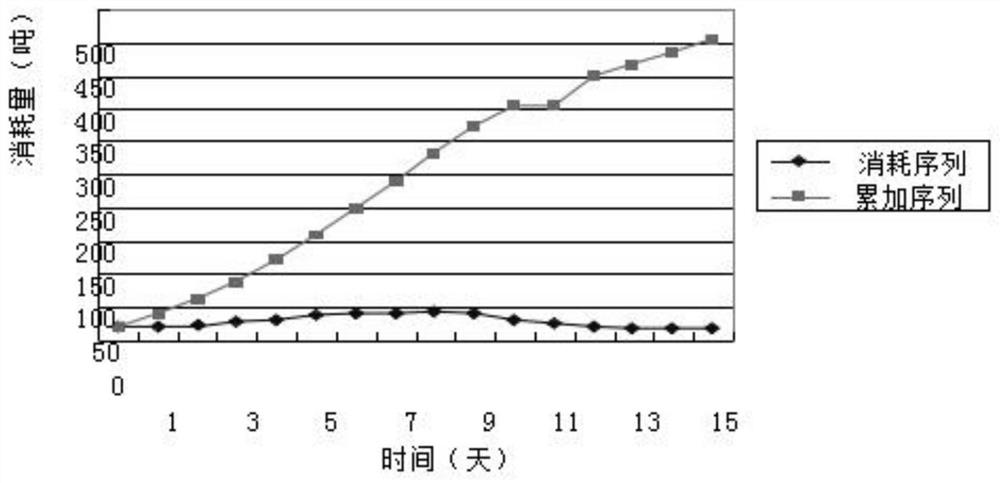

[0053] 1) Using the idea of segmented linearization, the logistics material consumption process throughout the entire logistics support process is divided into multiple stages;

[0054] 2) Assuming that logistics material consumption is a linear process in a short period of time, a low-level material consumption prediction model is established:

[0055] x k+1 =X k +V k Δt(k≥0),

[0056] Among them, V k is the material consumption rate between the k+1th data report and the kth data report, then: V k =Δx / Δt=(X k+1 -X k ) / Δt, through continuous acquisition of actual material consumption data, an approximately linear growth logistics material consumption curve is established;

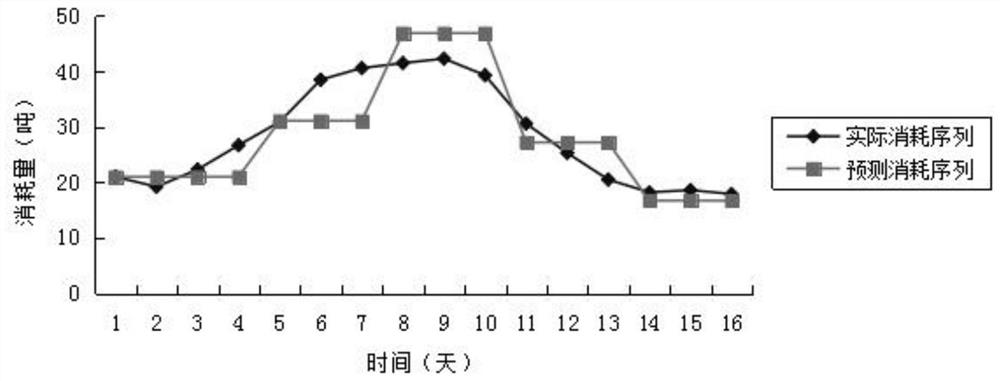

[0057] S2. Perform self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com