Protective cover structure

A protective cover and double-layer structure technology, which is applied to electrical components, casings/cabinets/drawer parts, electrical equipment casings/cabinets/drawers, etc., can solve problems such as inconvenient use, poor protection effect, and heavy weight , to achieve the effects of reduced damage, low manufacturing cost, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

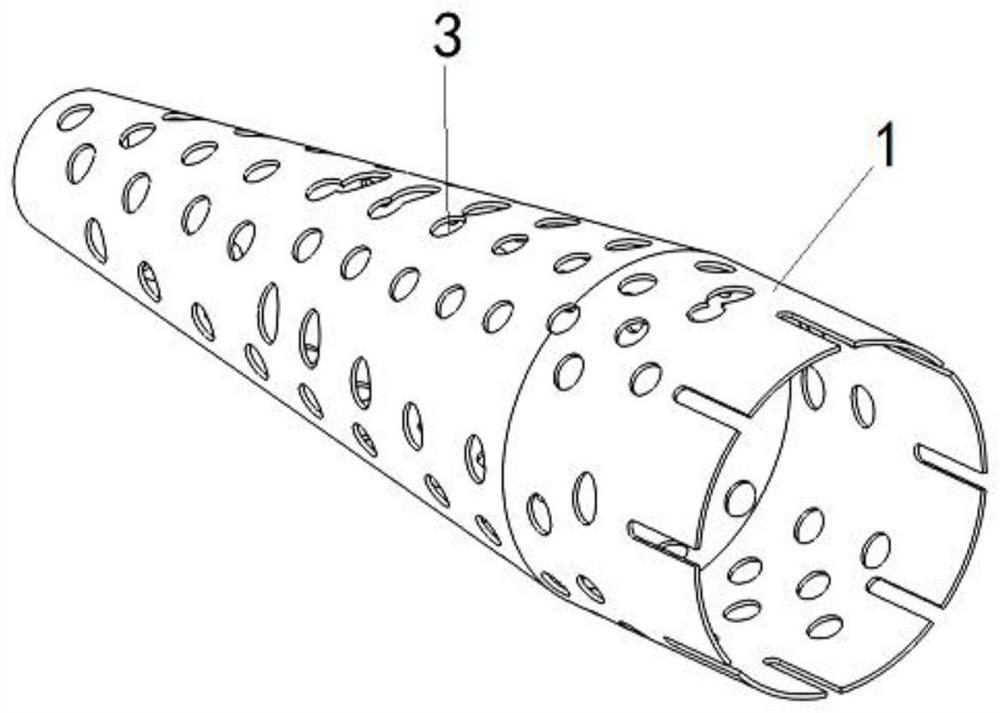

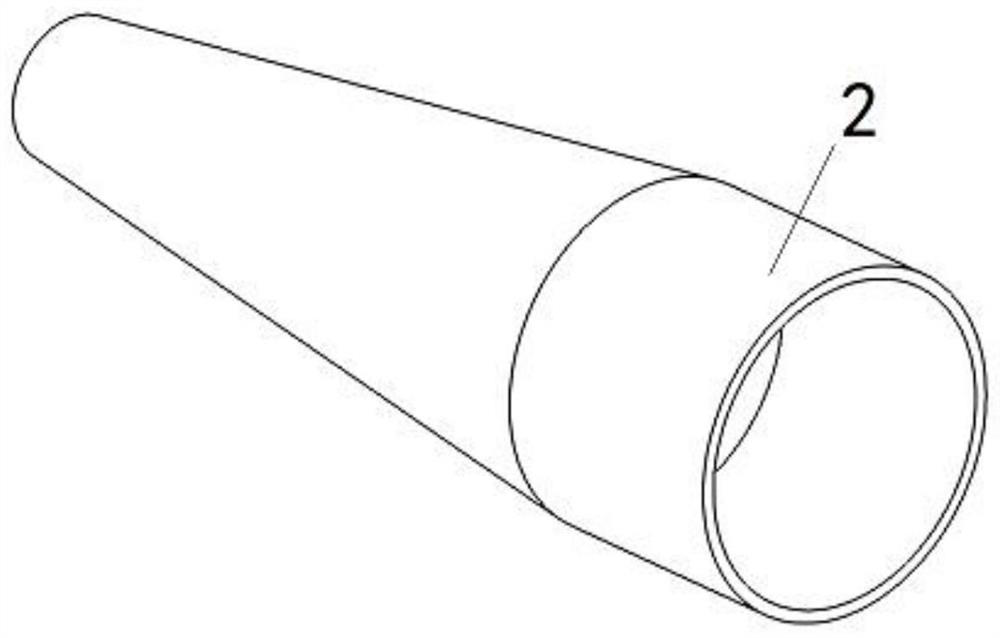

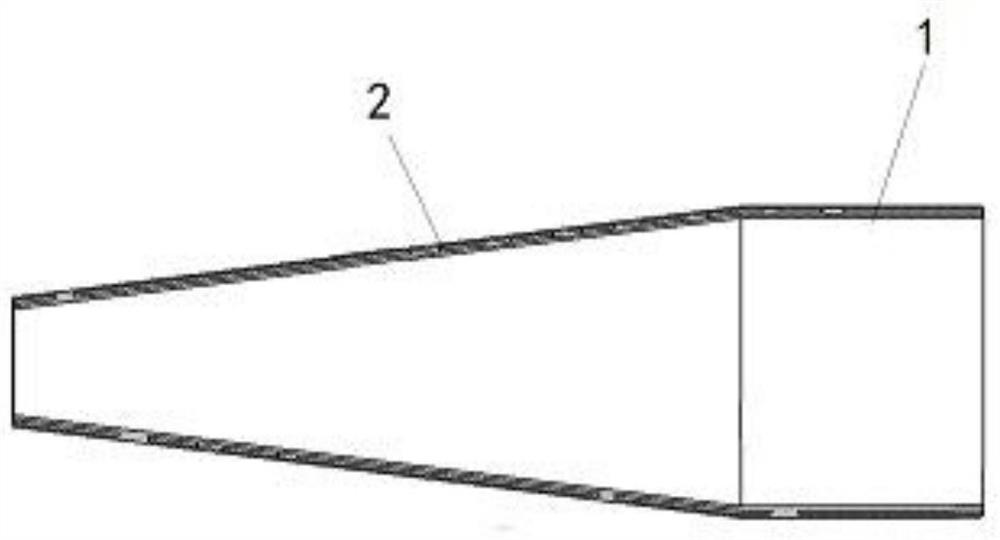

[0019] see Figure 1~3 , the embodiment of the present invention provides a protective cover structure, the protective cover structure is an integrated double-layer structure, the inner layer is the protective cover frame 1, the outer layer is the protective cover body 2, and the protective cover frame 1 is embedded in the In the protective cover body 2, the protective cover frame 1 is processed and formed by non-metallic materials, and the protective cover body 2 is foamed by placing the protective cover frame 1 in the mold and then injecting nano-reinforced impact-resistant materials into the mold forming.

[0020] As a preferred embodiment of the present inventio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap