Automatic suspension chain spraying assembly line

An assembly line and catenary technology, applied in spray booths, spray devices, liquid spray equipment, etc., can solve problems such as long cycle time, poor spray paint effect, and serious personal injury, so as to improve spray effect and reduce physical handling , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

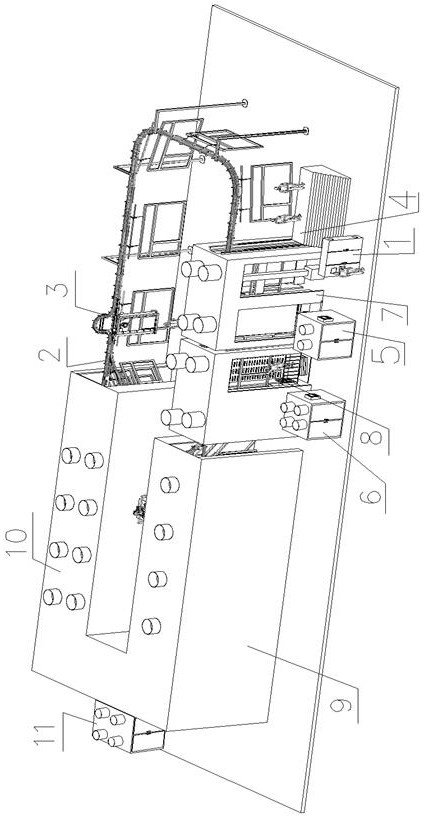

[0041] An automatic catenary spray assembly line, which consists of: base plate base 12, said base plate base fixes the master control cabinet 1, catenary spray line chain track group 2, chain feeding mechanism 3, manual feeding area 4. Electrostatic generator and pumping station 5. Industrial humidification room 6. Automatic spraying area 7. Manual paint repair area 8. Leveling area 9. Drying area 10. Heat exchange room 11. The heat exchange room is connected to the The drying area, the drying area is connected to the leveling area, the drying area is connected to the catenary spray line chain track group, and the catenary spray line chain track group is connected to The arrangement chain feeding mechanism, the leveling area is connected to the manual paint repair area, and the manual paint repair area is sequentially connected to the industrial humidification chamber, the electrostatic generator and the pump station, the manual paint repair area is connected to the manual fe...

Embodiment 2

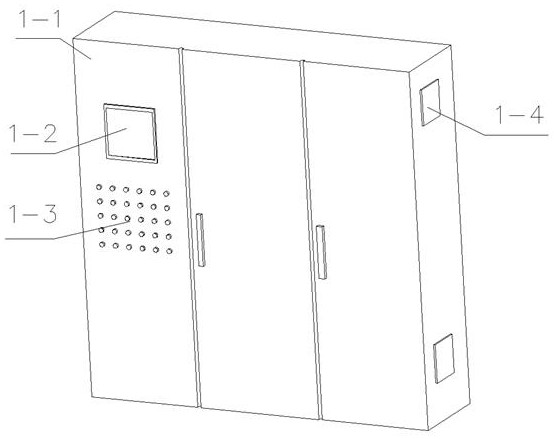

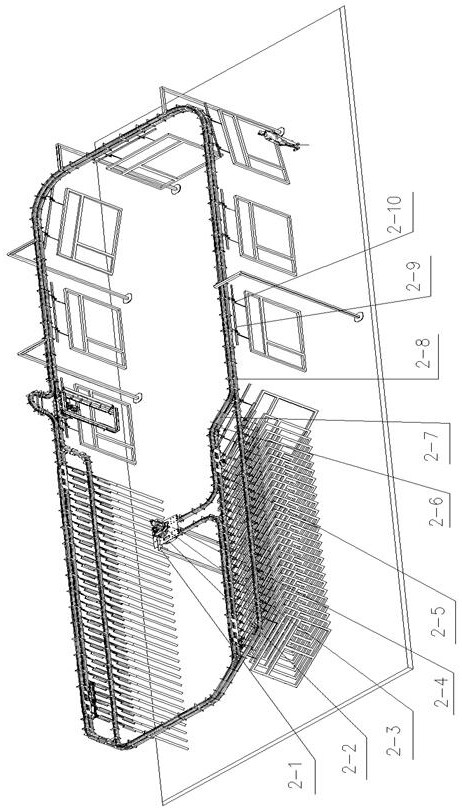

[0043] For the automatic catenary spraying line described in Embodiment 1, the master control cabinet includes a cabinet 1-1, the front of the cabinet is connected to a screen 1-2 and a knob 1-3, and the front of the cabinet is The side is connected to the ventilation fan 1-4; the catenary spray line chain track group includes a bracket 2-1, the bracket is connected to the connecting plate 2-2, and the connecting plate is connected to the drive motor 2-3 with a reducer , the drive motor runs through the sprocket 2-4 connection with the chain section 2-5 of the catenary spray line in the upper slide rail group 2-6, and the chain section of the catenary spray line is connected with a slide The dolly 2-8 in the rail group 2-7, the pendant 2-9 and the hook 2-10 walk.

[0044] The main control cabinet is mainly used to control the running speed of the entire automatic catenary spraying line, the spraying parameters in the automatic spraying area, the drying parameters in the drying...

Embodiment 3

[0047] In the automatic catenary spraying assembly line described in embodiment 1, the described distributing chain feeding mechanism includes a catenary spraying line chain section 3-2, and the catenary spraying line chain section is connected to a trolley 3-3, The pendant 3-4 and the hook 3-5, the pendant pushes the connecting block 3-27 to rotate along the pin shaft 3-25 on the bracket 3-26, the shaft of the pendant clamps the block 3-28, The chain link of the catenary spray line rises along the slide rail group 3-1 and separates from the trolley. The shaft on the pendant is pulled back and hooked by the hook 3-22 along the guide post 3-21, and the cylinder 3-20 drives the hook, and the motor 3-7 drives the shaft 3-17 on the reducer 3-8 to rotate; the shaft is connected to the gear 3-15, and the gear meshes with the rack 3-16; The bar drives the trolley, the pendant, the hook, and the open-type slider 3-19 to move downward along the cylindrical guide rail 3-18; the spring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com