Functional modular plutonium contaminated soil ex-situ leaching decontamination method

A technology of contaminated soil and functional modules, applied in the restoration of contaminated soil, etc., can solve the problems of groundwater pollution, difficult control of operating conditions, unpredictable decontamination effect and continuous repair time, etc., to save reagent costs and reduce secondary The amount of waste, the effect of achieving continuous operation and automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

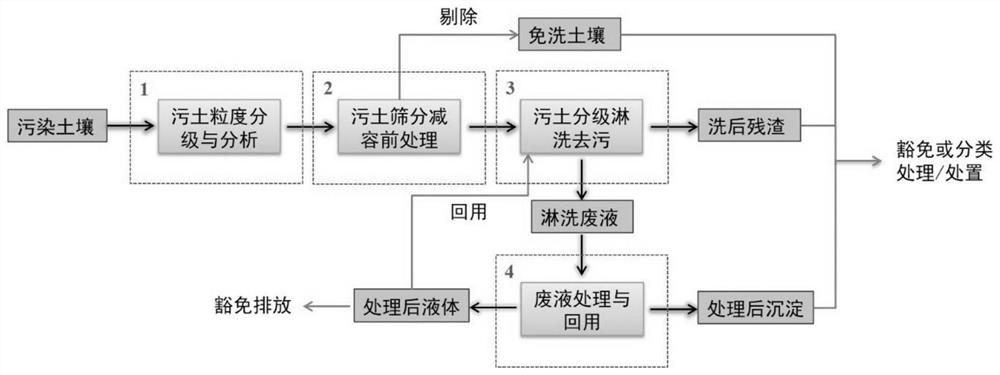

Method used

Image

Examples

Embodiment 1

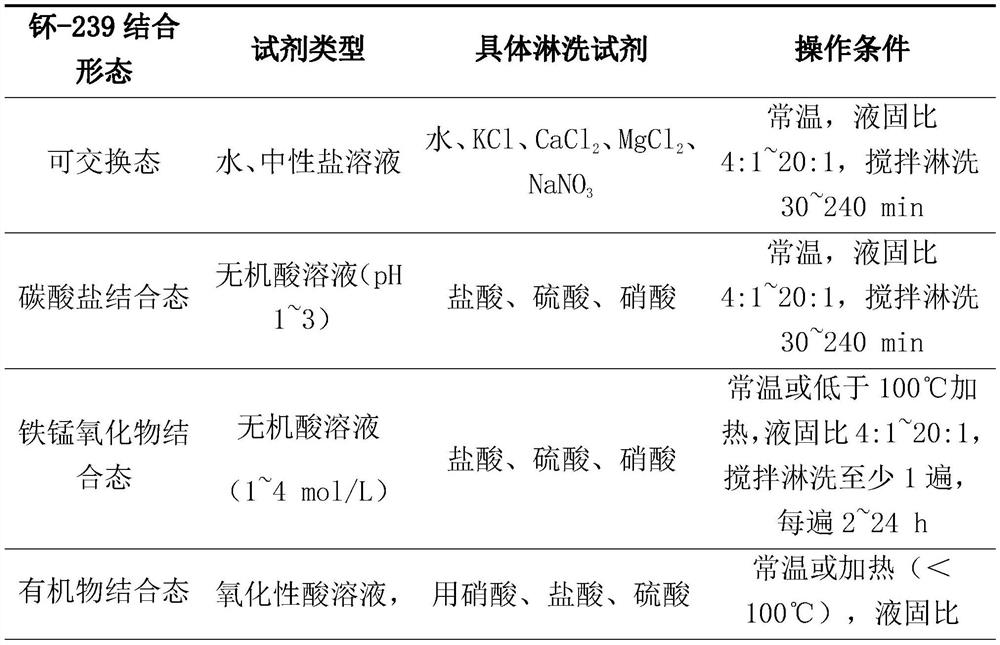

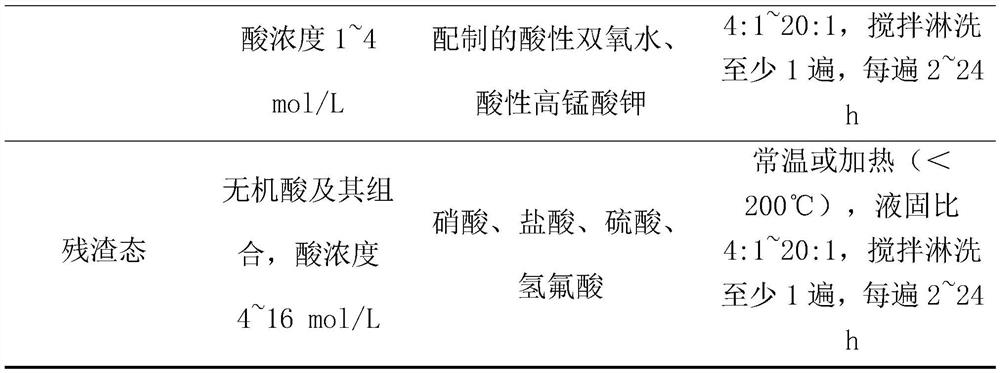

[0044] (1) Classification and analysis of soil particle size:

[0045] ①Take 2kg of plutonium-contaminated soil (plutonium-239 activity concentration>1×10 4 Bq / kg), after passing through a 20mm sieve to remove stones and sundries, use a vibrating sieve to divide the soil into 6 sub-samples of particle size ranges: ⅰ) stones and gravels, 2-20mm; ⅱ) extremely coarse Sand, 1-2mm; ⅲ) Coarse sand, 0.5-1mm; ⅳ) Medium sand and fine sand, 0.1-0.5mm; ⅴ) Very fine sand, 0.05-0.1mm; ⅵ) Silt and clay, <0.05mm ;

[0046] ② Weigh the sub-samples in each interval separately, and then use a ball mill to crush the sub-samples in the first four coarse-grained intervals to 160 mesh;

[0047] ③ All sub-samples were subjected to mixed acid full-melt treatment, and three groups of parallel samples were analyzed in each particle size range, specifically: Weigh about 1 g of sub-samples into a polytetrafluoroethylene beaker, add 10 mL of hydrofluoric acid, 5 mL of concentrated nitric acid and 5 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com