Photocuring 3D printer screen light intensity adjusting method and adjusting device

A technology of 3D printers and adjustment methods, which is applied in the direction of manufacturing auxiliary devices, 3D object support structures, manufacturing tools, etc., and can solve problems such as the decline in the accuracy of printed models and the lowering of the printing quality of LCD light-cured 3D printers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]The method and device for adjusting the light intensity of the light-curing 3D printer screen provided by the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

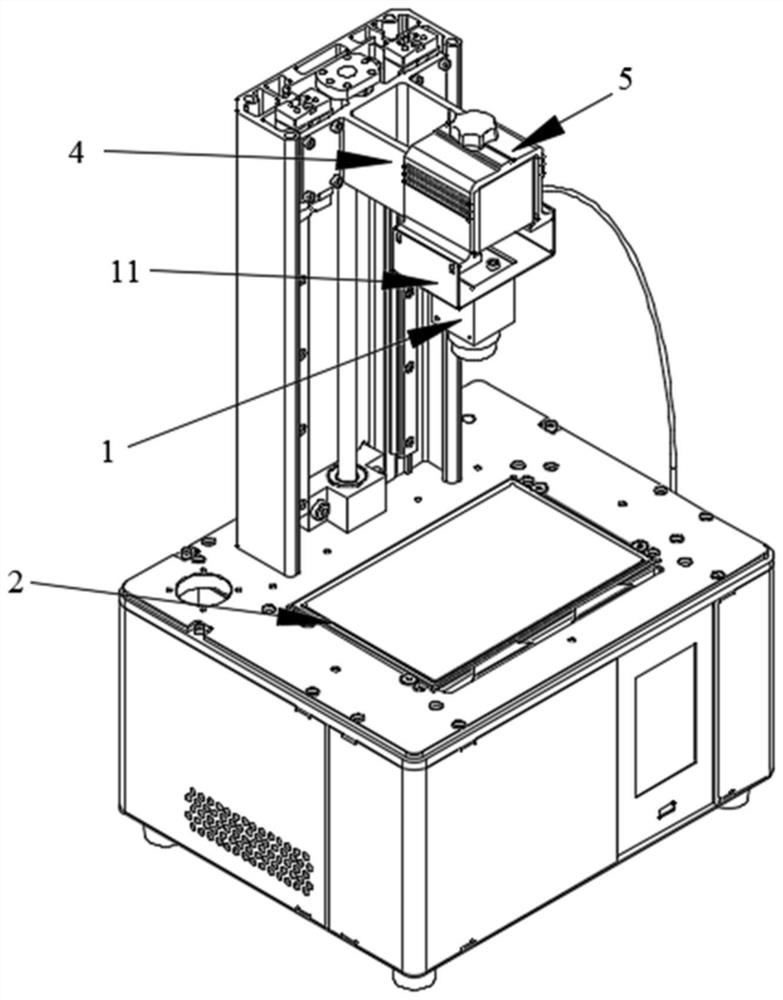

[0041] The present invention provides a device for adjusting the light intensity of the screen of a light-curing 3D printer, which is used to adjust the light intensity of the screen of the light-curing 3D printer, such as figure 1 As shown, the device for adjusting the light intensity of the light-curing 3D printer screen includes a light-intensity detection module, which is connected to the light-cure 3D printer. screen image processing.

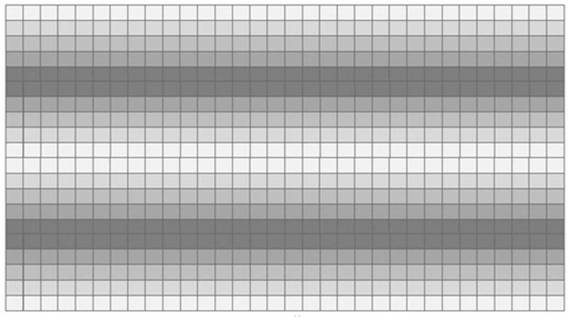

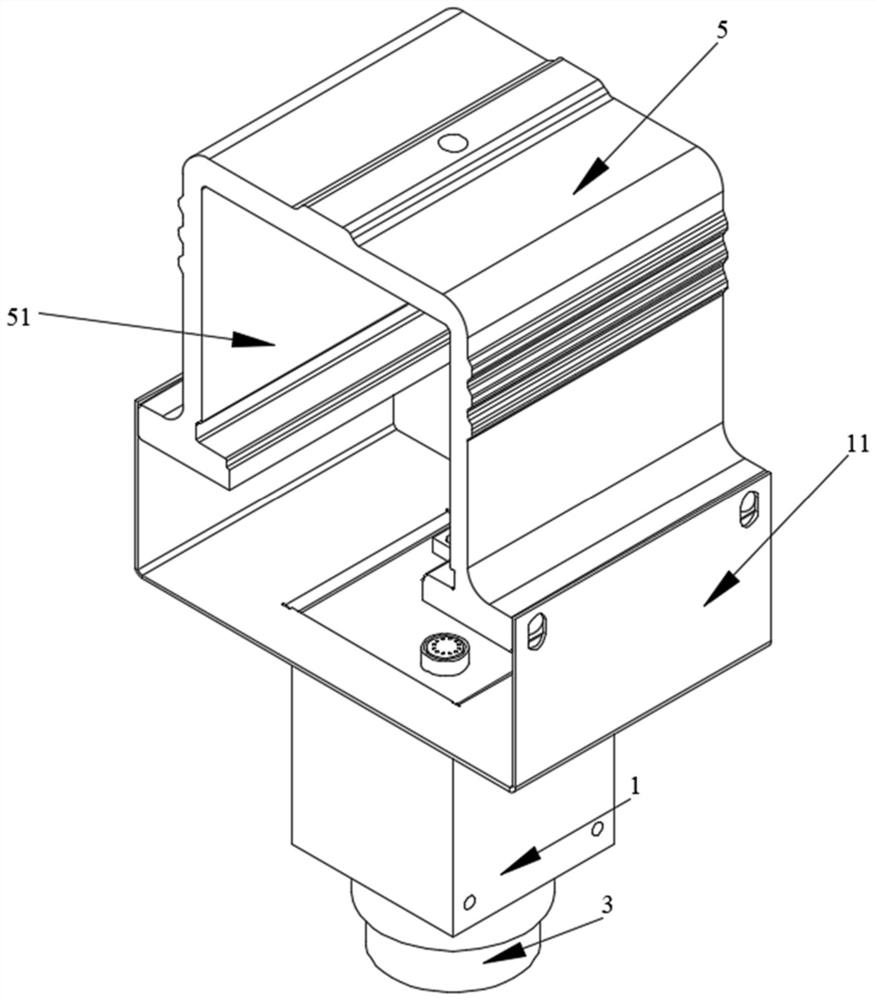

[0042] Preferably, the light intensity detection module includes a black-and-white camera 1 and a processing module. The black-and-white camera 1 is connected to the Z-axis column of the photocuring 3D printer and the black-and-white camera 1 is set toward the screen. The black-and-white camera 1 is used t...

Embodiment 2

[0051] This embodiment provides a method for adjusting the light intensity of a light-curing 3D printer screen. The light-curing 3D printer screen light intensity adjustment device provided in Embodiment 1 utilizes the light-curing 3D printer screen light intensity adjustment method to adjust the light intensity of the light-curing 3D printer screen. Light intensity is adjusted.

[0052] Such as Figure 4 As shown, the light-curing 3D printer screen light intensity adjustment method includes the following steps:

[0053] S0. Install the light intensity detection module on the photocuring 3D printer.

[0054] First, install the light intensity detection module on the cantilever 4, adjust the horizontal adjustment screws on both sides of the camera bracket 11, so that it can capture the entire forming range of the screen, and adjust the lens focal length of the black and white camera 1 to make the captured image clear. Then, use the USB data cable to connect the black and whit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com