Soil nailing wall support construction process

A construction technology, soil nailing wall technology, applied to sheet pile walls, foundation structure engineering, excavation, etc., can solve problems affecting the overall quality of soil nailing walls, groundwater seepage, etc., to reduce concrete holes and erosion , Improve the effect of installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

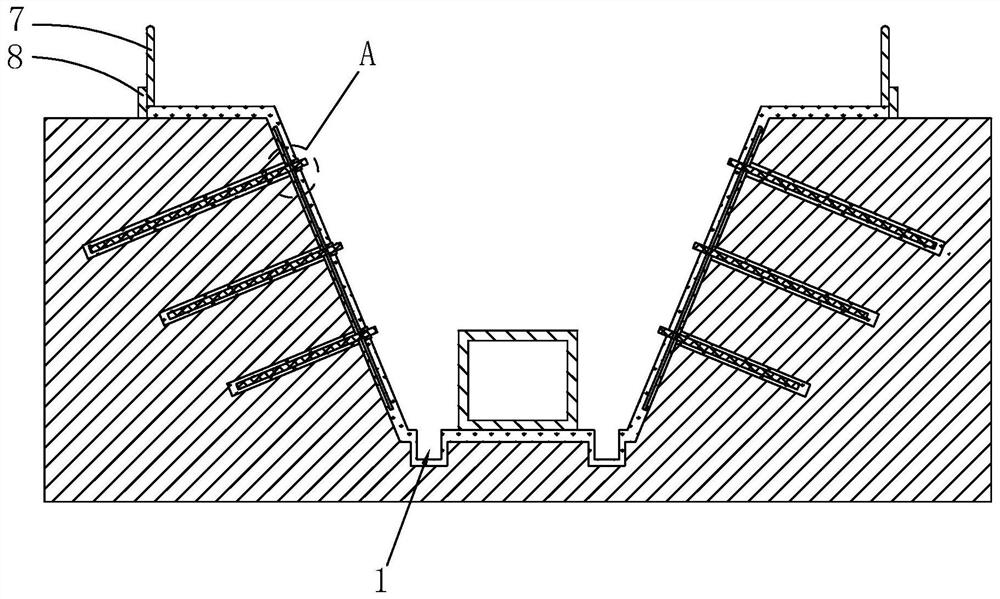

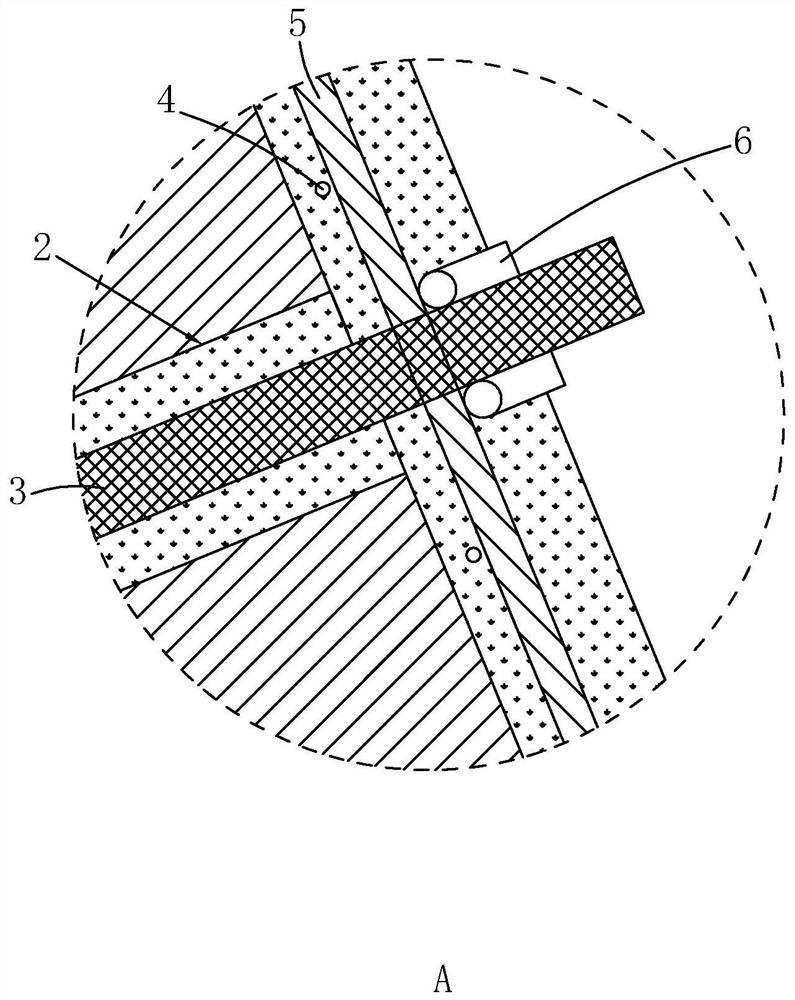

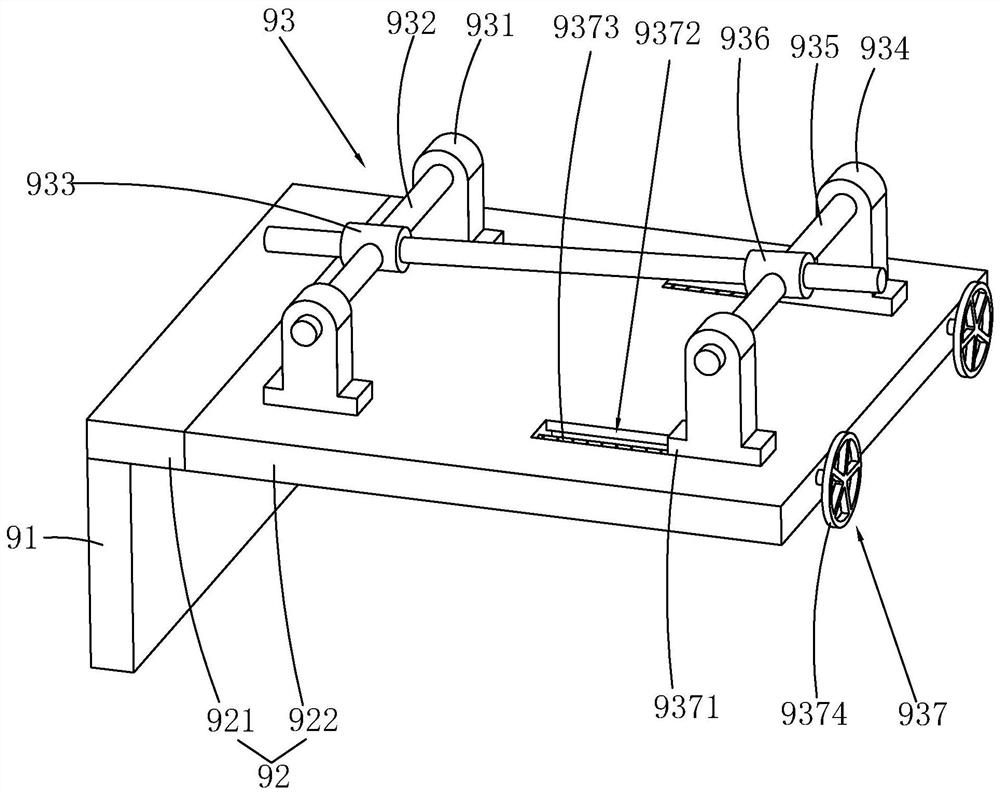

[0050] The following is attached Figure 1-3 The application is described in further detail.

[0051] The embodiment of the present application discloses a construction technology of soil nailing wall support, referring to figure 1 and figure 2 , the technical steps of the soil nailing wall support construction technology are as follows:

[0052] S1. Earth excavation:

[0053] S11. Excavation of foundation pit: Excavation combined with mechanical and manual slope repair is adopted. During the mechanical excavation, the underexcavation amount is not more than 100mm. Excavation, measure the slope and flatness of the slope after the excavation is completed;

[0054] S12. Manual excavation of weep holes and drainage ditches 1: According to the geological seepage situation and the construction requirements of weep holes, manually excavate weep holes, every 8m of weep holes 2 -12m 2 Open one, if the geological seepage is high, increase the number of weep holes, and excavate d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com