Aluminum alloy template cleaning equipment

A technology of aluminum alloy formwork and cleaning equipment, which is applied in the processing of formwork, on-site preparation of building components, construction, etc., to achieve the effects of low cost, convenient cleaning, and dust prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

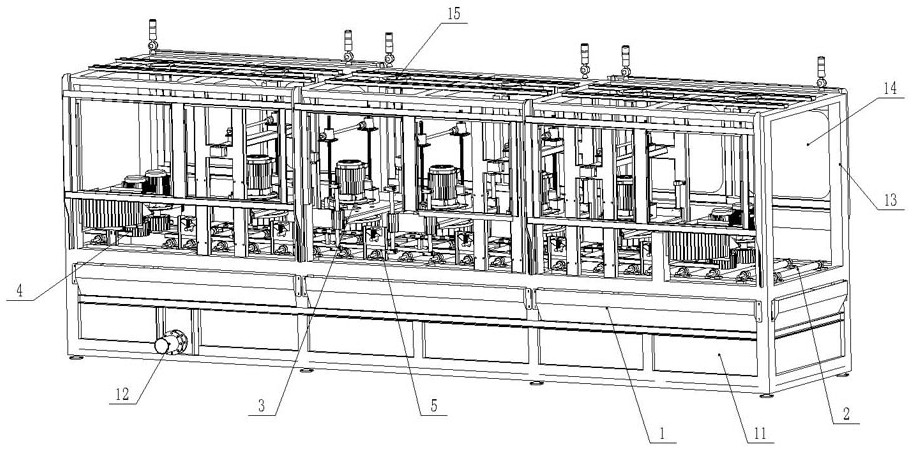

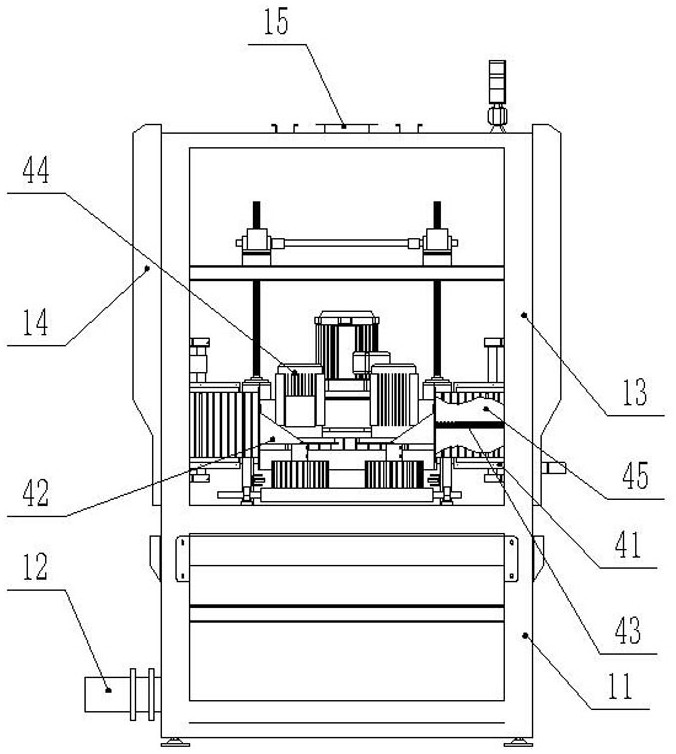

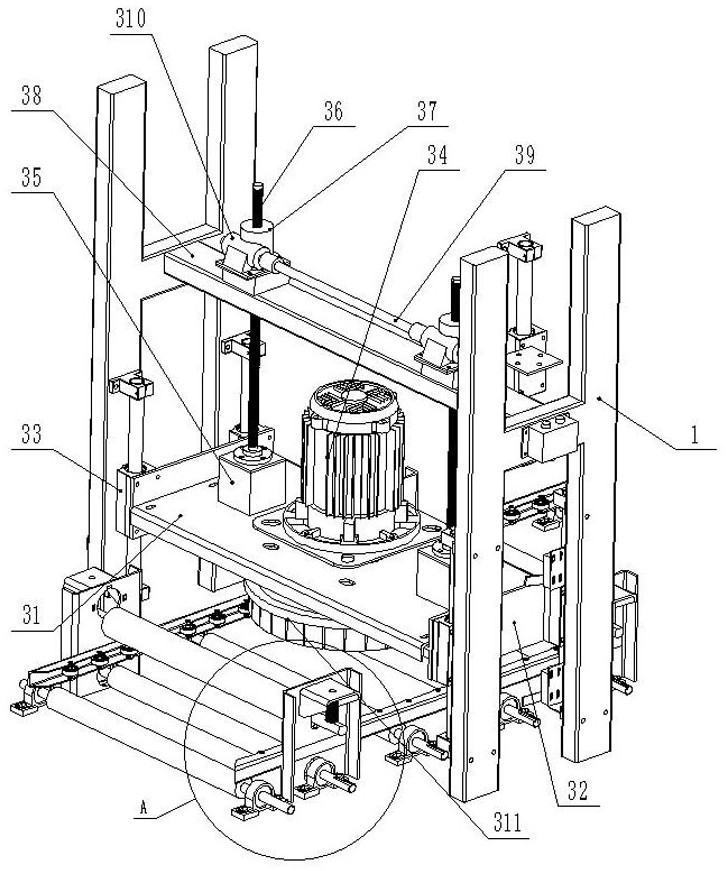

[0027] Such as Figure 1-Figure 4 As shown, the aluminum alloy template cleaning equipment includes: a cleaning frame 1, including a reservoir 11 for storing the cleaning liquid flowing out of the spray system. , the water reservoir 11 is provided with a drain outlet 12, and the top of the reservoir 11 is a mounting bracket 13 for installing other components of the cleaning equipment. The side and top of the mounting bracket 13 are provided with cover plates 14, and the side cover plates 14 can be opened and the side cover plate 14 is provided with an observation window, and the top cover plate 14 is provided with an exhaust port 15 .

[0028] A plurality of feed rollers 2, a plurality of feed rollers 2 are arranged side by side on the installation bracket 13 above the reservoir 11, the feed rollers 2 rotate under the drive of the feed motor, after the aluminum alloy formwork to be cleaned enters from the vault, The aluminum alloy template to be cleaned is placed flat on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com